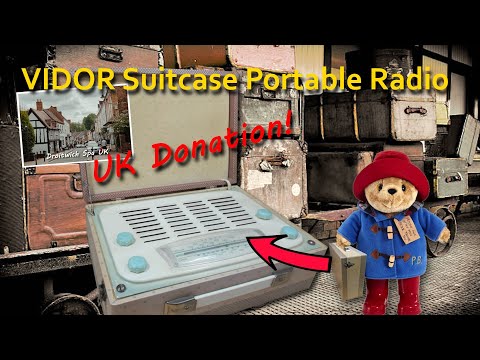

Vidor Suitcase AC/Battery Henley Portable Radio - Model CN426 - 1953

[Music] G'day and welcome back. Today I'm going to work on this little suitcase. I think it's a radio. This was sent to me by Darren in the UK. Darren lives in Drotwich Spa which is around about a 30-minute drive from Tipton in the UK, which is where my family originated from.

We did a four or five week driving trip through the UK back in 2015 and we dropped into Tipton to have a look around. So Darren sent this radio to me, so let's have a look at it. Now it's a very neat little suitcase shape. In fact you would not think that was a radio. I'll have a look inside. I haven't done much to this. I haven't looked at it for

a couple of months actually. It's a pressed steel fascia and it's got little cooling grills there for the speaker. The dial is nice and clear and the markings on there are good too. Vidor. Vidor is the brand and it's got

long and medium wave. So assume that's volume. That's tuning. On off maybe. Oh it's

on here. Look battery. Battery off and mains. So it's a mainset as well as battery. So that must be long and medium wave. I noticed there's some wires going up here in the bottom right hand corner. Thinking this is an antenna. There's two

screws down the bottom. If I undo those I guess I can lift this panel up and we'll see where the batteries are and the radio itself. This screw was probably captive if you lift it up. Oh gaw it

doesn't want to come up. There's one two three four valves. That'll be 1.4 volts I would imagine. Tuning gang. There's a capacitor there. Transformer. Transformer there.

So it's probably not a hot chassis set. Metal rectifier. There's a speaker. Not terribly big.

And over here's all the front end. On the side is a smoothing cap and I think that's the battery mains selector there. There's some battery plugs pushed into a block of wood there. There's the mains lead and Darren said he'd remove the plug. I don't think they're resistors. They're just a spring with wires attached. I'm not sure what that's about.

And down in the corner here is the socket for the power. There's the corresponding pins. So when you lower this top plate down it engages in the socket there. There's a sticker on the bottom.

It's a Vidor and the model number is CN426. That's what I need. I'll go and see if I can find some info on it. I found plenty of information on the internet and I've downloaded it. One thing I did find out was these two springs are actually a switch. And there operated

by the stay attached to the lid so if the radio is still powered and you close the lid the little stay shorts the switch out and you get a feedback signal through the speaker. Another thing I found out was it says stand this on its left edge to open it but I should have had it down there. Oh, spare parts. So yeah that makes it a bit easier to work doesn't it? Okay. I've undone the mains cord and it says to thread it through this gap here.

The voltage selector is on 230 250 so that's fine for us. So I'll close it up and we'll try putting some power on it. I'll give it a test. I put it on mains which

is there. Medium wave is over there. I'll put some power on. Dim bulb of course. This should come on almost straight away. I'm not making any noise.

Just pulling a few watts. Should be something down here. Nothing. Nothing at all. I've repositioned the mains plug from the bracket down here onto the radio so I can power it. I'm going to put some power on.

According to the schematic this should have about 110 volts on it. It's got nearly 100 so that should be enough to make it work. These valves are in a series string so I need to check to make sure they're getting their voltage. I think I need to

take this chassis away from that front plate. I can't get the knobs off. I'm using my normal cloth method to pull them off.

They will not move. They will not move and I do not want to break the knob itself from the stem. So I'll try something else. I'll undo the screw again.

The black ring there is the spring that's going around the knob shaft. So I'll see if I can lever it up. It's got to be better than trying to pull on it. It's off. It's not damaged. No cracks. So

I'll do the other three the same way. I ended up removing the entire chassis, the aerial, the speaker. Everything's out of the radio so I could work on it. I'll put power on. This is the plate. So that's got 81. There's the

screen next to it. 84. That's okay. The grid is number six. That one there I think. Oh that's got 14 on it. Yeah that's no

good. I'll turn the power off. That looks like the coupling capacitor. That is leaking. There's the

output valve. There's the grid and there's the coupling capacitor there coming off the plate. So that's C19. C19 is a 0.01uF. So I'll put a new one of those in.

I've put a new cap in. I'll try that out. Already the Watts have dropped so it was about 11 or more I think. Let's have a look here and we've got zero volts. So

that's working fine. I'll change that valve because it's probably cooked it by doing that. That's a 3V4, that one there. So I'll just change it over. Okay I've changed that valve. Put the power back on again. Got my generator here.

We'll actually put a little signal into it. Oh yeah that's working. Okay so let's come back one. So that's the plate. That one there is the grid for the detector. Nothing there. I can just hear it. Just hear it. Here's

the volume control. The signal's going through this coupling capacitor onto the grid of this triode, no, pentode detector and it should have come out the plate eventually but it's not doing it. So maybe that valve's crook as well. I decided to test all the valves so I've taken them out. I tested them. Some are a bit weak so I

replaced them with good ones. With the tested valves in I'll see if it's going to make any difference. I don't think it will because the old valves weren't that bad. Once again I've got my little generator there. I'll turn him on. I'll put the little test lid on the grid of the output valve. That's working.

It should be on this side too. Yeah now there's the grid of the triode and there's nothing. There's nothing there. I just touched that by accident. So I wonder why that's not working. This is the preamp again and I'll check the voltage across the filament and we've got 6.3.

6.3. That should be 1.4. I'll try this. Should be three volts or something shouldn't it? Two. That's three. It's moving around a bit. Now this one's the IF amp. What have we got there, one volt.

Well let's keep going. What's this one? That's 0.8 or 0.9. That's why they're not working. All the voltages in the filaments are wrong.

I've taken all the valves out. I've been testing these shunt resistors here that go across each filament and they're all tested fine within 10 percent. As a simple example there's one there. 150 ohm and it's reading 140. So they

were all okay. I also tested here and I've got B plus. So B plus is here. Needs a ground of course. So we should have the potential to power these filaments. The only thing I could possibly think of is this capacitor here is leaking and dragging down the voltage. I'm not 100 percent

sure on these string... you know filament setups. So I might I'll take that out. I actually replace it and it's a 0.05. Where is

it? 6. It's a 0.05. So I'll put a new one of those in and see if that fixes it. I've replaced that capacitor and refitted the valves. I've got my generator here. I'll

turn that on and power it up. All right let's see. So we should get a tone there. Tone there. And oh there's something there. It's not very good but it's there. This sheathing here has got

the wires in it for the volume control. This is the center of the volume control. So I've put a little clip on there. I changed over the signal tracer to tracer mode and I'm on the volume control coming in from the front end of the radio and I'll try and tune it. Well we're listening to the speaker in this now. So there's

something getting through. There's something getting through. It sounds like the oscillator is not running but I think what I need to do is just replace all the paper capacitors that one that I changed up here was completely shot. So too hard to troubleshoot with so many areas with faults in it. I'll get rid of all those. I'll come back

and we'll see if it'll work then. I've replaced the paper caps. There's a couple down there. Another one there and of course the one that was across here. I haven't finished that one yet.

I've left some of the electrolytics in but I'll get to them later. I'll just show you something I found. This is the 3V4 output valve and this had that red capacitor up here before. It's now sitting under here. When I touched the

audio generator on here and over here the signal got through but if I put it on the grid it didn't come through. So this valve wasn't working. So I had a look around. All the solders are okay but I turned it over and I found the pin on this one here is broken off. This is the top of that valve socket and this is the pin that I was looking at from the bottom side and it should have one of these silver contacts on both sides like this one here. This is broken off and you can see the little brass end where it's broken off there. So I need to fix that somehow.

One of these contacts in here isn't being used. It's either that or that one and I can maybe extract it and put it back into this one. Here's the broken one here. This is the spare and with a bit of

luck if I straighten and push it back I can overcome the little barb that'll be in there and we can get it out. Let's try and un-solder these two wires here. Probably easier to cut them off actually.

I think I'll cut the top off. That'll make it easier. I'll use a bit of solder wick here just to get off any residual solder that might stop it going back through the hole. All right let's have a go pushing it. There

we go. Oops, now I split it. I'll straighten that up again so hopefully it will push through. There we go. I should be able to

grab that and pull it straight out. Here's the replacement one and that's the one that's broken. You can see the tine's broken off. So I'll put this one back in and hopefully that valve will start working. I'll make sure I put it in the

right hole. There's the end of it there. I should be able to grab it and pull it through. I hope.

There it is. All right I'll solder all that back together and we can try the radio out again. I've soldered these two wires back on. I've got a tube in there now, or a valve. I'll put some power on. Now this was running at about eight watts before with that faulty socket and we didn't have that amount of noise from the speaker. It sounds like it's trying to

receive but it's not. I'll check that the local oscillator is working. That's it there and that feeds into pin four. I think I think it's four and here's the antenna signal, the grid. So that's going into six. We'll check those. I've got the scope running.

I'll put an earth on here. It's picking stuff up. It's working. This is the base of the mixer. This is a DK92. One, two, three, four. It's either three or four. It's a bit hard to look at the

diagram. There it goes. So let's pull that back. Oh not very good. Try it on four. That looks better. Now if I tune this it

should tune. So that's the oscillator. So the oscillator is working. This is the antenna wire going in. So that's the grid. And we're not getting anything. Now

that'll be a reflection of the oscillator here. I'll try injecting a signal through the radio and see where it's cutting out. I've got my frequency generator here at 470 which is the IF frequency. (It's really 475) This is

the grid of the mixer. So that's the antenna signal coming in and there's nothing coming out. So that's the plate going into the first IF. Oh nothing there either. This is it coming

out of the IF transformer. And there it is. So it's there. Not there. That would indicate there's something wrong with that IF transformer. If I put my voltmeter here I can check that coil there and that coil's okay because it's running 90 volts through it. So 90 volts there. It's

going through the coil and coming out here. I'll take the transformer out and check it and just make sure it's okay. I have the transformer out. I'll have a look inside. I'm really not confident with this whole idea. Anyway let me bend these back and that should allow me to take the cover off. We'll

have a look inside. There it is. Pretty simple. I can't see anything wrong with it. I'll test the resistance across the primary there. It's supposed to be 20.3. That's 22.8. And this is the secondary and that's the same 22.6. It's a bit high but I don't

think that's an issue. The only other thing would be the capacitors. I could try lifting one off or one end off and test them I suppose. I've lifted one of the legs on each capacitor and the schematic says they should be 63 pico farad. What's that? 63 isn't it? It's exactly 63. I'll swap it around. We'll try the other one.

I've swapped onto the other capacitor there. So that's also 63 and that's 64. I don't think there's anything wrong with it. I'll reassemble it and do some other testing. It's a little hard to see there. I've got the transformer mounted in a vice. There's the two capacitors.

I've resoldered them and I've got a load of clips on here. This clip here is the generator going into the primary. This is going off to the oscilloscope so I can measure it. I can see it.

The earth is going to the second side of the coil there. The other side is connected to the second channel of the oscilloscope. So we'll be able to see what's going in and what's coming out. I have my generator set to 470 still. If we look at the scope now we've got a very good sine wave. I'll switch on the second channel.

That'll be a blue line. There it is. There it is. Now I'll just adjust it. We should get something. There it is. It's not very good. That's about maximum there. So I'll adjust the frequency and that blue line should increase. There it goes.

All right so 410. So if I put it back on 470 I'll put it on 475. I had a red clip lead on here but I don't need it because it all gets grounded in the oscilloscope. This is the primary end of the transformer and if I adjust it that blue line should get bigger and bigger. Or the blue sinusoidal wave and it's moving up. That's about it there. That's about all I

can get out of that one. About maximum there. I'll go in from the other end and this is the secondary.

And that's that's adjusting okay. Okay that's peaking okay. I'll turn that down. Yeah of course when this is fitted to the radio its frequency is going to change. It's not going to be the same as it is sitting in a vice. So it'll have to be adjusted again when I put it in the radio. Something I noticed was this lead

here is sticking out past where the case would go. And I thought maybe it's shorting to the case but it has a liner in there so I don't think it would. I'll bend it back anyway. I'll bend them all make sure they're clear. I'll put the cover back on. I don't think it'll make any difference but when I soldered the capacitor back onto one side of this coil here the coil wires have made up three strands and one of the strands wasn't soldered onto the leg. So I cleaned it up and

soldered it back on. As I said I don't think it'll make any difference to the operation of the coil. Now another thing of course is I could have dislodged it when I unsoldered the capacitor. And I also replaced the IF valve. I went and pulled all the valves out and made sure all the sockets were okay. And I thought

I'll change this one because I got one yesterday from a friend. So I'll stick that in. It's a new old stock one. So a couple of changes there. We'll see what it does. Oh that's a different sound. Oh look at that. It's coming through.

Oh I'm excited. I'll put the generator on. I'll see if I can tune that IF can. I'll put some power on. We'll see what happens now.

Oh yikes. I'll turn that down. Wow. I think I might have sorted it. I'll

put it back on again. Yeah I'll adjust the IF again. See if that makes and it is. Oh wow. All right. I'll flip it over and do the top bit. Okay I'll do the top bit.

Yeah that was a long way out. All right that looks good. I'm ready to test it. I've taken the generator off and I put an antenna on. Some power. It's about right and it's making noise. It's making good noise.

Oh look at that. It's gone. [Music] I love it. Wow this has been such a challenge for me. I'm not even sure what fixed it. Was it changing the valve was probably the most likely. Of

course we had to repair the base on that valve there. I repaired a wire in there. I'm not sure which one was the one that made it work but it does work so. Oh it used to work. [Music] Okay anything up here? No that's the end station. Before I get too excited and put all back together I need to go and change the electrolytics. There's about two or three

that need to be done. So I'll do that. I don't know that I need to do an alignment. It seems to be working all right. But I'm very happy. I just went and said

to the wife I don't know what's wrong with this thing. Yeah but it's working so fantastic. I'll do those last few electrolytics. I'll come back then. I'm not sure what to do with this rectifier. It is working. I can't imagine this radio is going to be used a whole lot. I'll see how hot it is once I turn the power off. I'm not touching it

while it's running and maybe decide then. The power's off. I put a ground on it. It's not even warm. Yeah hold the side on that. You know quite happy to leave it there if it's not getting too hot. Yeah all right. I'll do all those things.

I'll come back. I've replaced the three electrolytic capacitors. I've left the old ones in situ so it looks original. But I've just got that one sticking up the top there and there's another little one around the side there. You can

barely see that one. And I've restuffed this main one. It's got two capacitors inside. I've restuffed these a number of times so I didn't show it in detail. I'll just quickly run through what I did. So as usual just grind off around the edges there and then remove it. Now this one gave me

some trouble. I couldn't get the end plug out. I ended up drilling two holes through the plate and putting my long nose pliers in there and twisting it out. The

insides wouldn't come out as one lump so I had to keep picking at it but eventually I've got it cleaned up. So I put two capacitors together and I've put the ground out through a hole in the bottom of the can. Because I had such large rivets on the end plate I put a little insulator plate in there to make sure I'm nothing shorted out. Just a matter then of winding the wires around the terminals and soldering them up. And then back to the workshop and just roll the edge over again. So that's

it and it looks good. It's come up nice. I'll set the radio up now to align the IFs using a meter. I've set the chassis

up so I can get to both ends of the IF transformers. I've got a meter on here. I have my generator set to 475. I'll put some power on and we should hear some noise. There it

is. So as usual just doing the IF alignment at the moment. So all I'm looking for is maximum deflection on that meter there. I'm not looking for any particular number. So I would think these will be fairly close. I'll get a little bit out of that one.

Try the next one. That one was right on. Right, I'm on the bottom side now. That one was close. Got a little bit out of it. That one was spot on too. So I'll run through them again and make sure they are perfect.

Then we can move on to the next step. The next thing to do is the radio frequency alignment. but I need the radio mounted back in the case. So I've cleaned it up and wow did that have some dirt on it. Look at that. It's come up like new. It is faded but it looks really nice. The sides

of the case are not going to come up. That's as good as I can get them but it looks pretty good. Doesn't look too bad anyway. I've put the radio back in its case so it's all assembled now.

I can now do the RF alignment and the RF alignment is to get the oscillator and the antenna gangs in the tuner here aligned with each other so that they both track exactly the same way and also it corresponds with the dial on the front here, the pointer. Now I do have the alignment instructions so that's pretty straightforward. First thing to do is align the pointer there with 2000 with the gang fully meshed. That looks pretty good. The next is to put it on to 500 meters on the top scale there and we put some power on and the signal should be there. I can just hear the signal and yeah it's off. It's out so I need to

adjust it. I'll put it back on 500. The adjustments are this one is the local oscillator padder. So I should be able to bring that up. There we go. Got the meter there. Okay so the local oscillator is aligned with 600 kilohertz.

Why is that? It's come right out that one. So now we're aligning the antenna coil with the local oscillator. That's about it there. All right so I'll put this on 1500 and 1500 is 200 meters so I'll wind this down to 200 meters and we hopefully will pick that signal up again. There it is.

That's a little bit out. These are the two trimmers we need to adjust. One's the local oscillator and one's the antenna trimmer. I don't know which one's which but you can check just by touching the tuning condenser here. So that's the

local oscillator because it's changing the tuning. This one will just kill it. So that's the antenna. So this one

should be the local oscillator. I'll adjust that and we should be able to bring it into the 1500. Okay that's got that and then we just trim the antenna. Because I've adjusted these two it may interact with these two here that I did earlier. So I need to go back to the 500 Meters and just adjust these again. Just check them. Come back and do these

again. If I keep adjusting once I finish adjusting I can call it quits. But if I keep adjusting I need to keep going back and forth. I'll do that off camera and we'll come back when it's all tuned up. I finished

doing those adjustments. I had to go back what three times I think just to get it right. So when I adjusted these guys here these two had moved. So I moved them then moved these two and went back adjusted them came back and they were okay again. So with that all done I remove all the test gear and we'll try it out. I put the radio

back in the case. I reassembled it. I locked it up turned the radio on and it didn't work. I

found that this valve here this is the one I changed in the end to get it to work and it's now it's working. But anyway that is intermittent. In fact there it is there I've turned it right up and nothing's happening. So it's intermittent

somewhere. I need to clean that and have a look at the valve base again. So I'll take it out. The pins aren't corroded but they do look a bit dirty. I'll clean them and one or two of them are a bit bent too as well. So I'll straighten them up and I'll just have a look inside the base there.

This is the socket and it looks okay. Some of the gaps look a bit big like that one there and that one there. So maybe I'll just try and close them up a little bit, retention them. I'll clean the pins up and reinsert the valve. I've found the problem this pin here is broken. So I'll have to replace that as well. So

maybe that was the problem all the time that socket wasn't making contact. So I'll repair that the same way as I did on the last one and I'll come back and we'll make sure it actually works. I repaired the valve base and I've put it back in the case. So we'll have a look and turn it on see how it goes. And there it is. It's cleaned up pretty well not too bad. I've got power on it so if I

turn that that way it should work. Now that's ABC radio and it's just above the or just below the 500 meter mark. So that's exactly where it should be.

So there's the sport channel now. TAB channel, the racing channel. Not going to get much up here. It's in the middle of the day so not going to pick up much. We'll go to

long wave and we should get the beacons up here somewhere. There's one. Another one here. There it is. So long waves working as well. Oh I'll tell you what what about

that signal to tell you that it's turned on when you shut the lid. Let's see if that works. Well you won't forget to turn it off. Okay so the idea of that was that if you had it on battery it would feed that positive feedback back into the output valve. All right. Where are we?

5.9 million. You've also got Linderman Island. So very nice. I'm really happy with this. I'll open it up. We'll have a quick look

inside again. Remind us what it looked like. Oh there's the inside. It's all very neat. I decided to

leave that rectify there. After running it for many hours yesterday that didn't get hot at all. So I'll leave it in there. If I take it out I've got to start putting resistors and all sorts of things in. So just easy. I'll just leave it there. It

seems to be working okay. There's a handy little holder here for the power cord. All right that's wrapped up. I can close

the lid for the last time. With that cord out of the way I can close this properly now. But this would have looked really nice when it was done. This would have been bright red. This would have been a cream color red down the bottom. Would have looked

really good. Once again thank you very much to Darren in Droitwich Spa for sending this over to me. I love it. It's fantastic. So I hope you enjoyed watching this and I hope you can join me next time for my next radio adventure.

2024-06-06 16:00