Research for Industries (RFI) Lecture Series: Matthew Realff & Christopher Jones

[Music] hi everyone and welcome to the research for industry talk today and i'm conor kelly a project manager in the azure global energy team focused on environmental sustainability software engagements with our customers in the energy industry and before i introduce the speakers i'd just like to point out the q a and so if you have any questions during the talk just go right ahead and put them into the tool and and after the talk we'll start running through those in a live q and a session so next i'll introduce the um two speakers today so the talk is out of thin air which is focused on direct air capture and we're privileged to be joined by professor matthew ralph and professor christopher jones and so professor ralph and works on the areas of energy and sustainability complex systems and biotechnology um and so both are out of georgia tech and professor christopher jones um is a professor of chemical and bio molecular engineering at georgia tech um directing research programs focused on catalysts of on co2 separation sequestration and utilization both have very extensive publishings and research programs and so we're really glad to have you here today and um i'd just like to introduce you and ask you to go ahead with the talk so thank you very much and over to you thank you for that introduction connor uh so the talk today is out of thin air direct air capture of carbon dioxide to walk our carbon footprint backwards and i'm delighted to be here with my colleague chris jones so as we get going i would like to start with our main messages of this talk uh just in case any of you don't get the opportunity to to join us for the entire time the first of those is is that we typically as scientists and engineers solve problems and create new ones in the process so the most classic example of this in the chemical engineering field is the fact that before the invention of the harbor bosch process which fixes nitrogen from the atmosphere we would have regular and repeated global famines but with the ability to create uh fertilizers from nitrogen fixed from the air we have essentially solved that problem which led of course to an explosion in population and as a result of an increase in population substantial increase in energy use second is is that history shows that we can respond in rapid and focused ways when we resource the science and engineering to do so and here are three examples of this obviously the manhattan project in the 1940s the moon shot in the 1960s in the human genome project in the 1990s climate change is the defining challenge of our current era if we don't solve this people will look back on this and hopefully reflect on what contributions we didn't or did make to this problem we need to solve this problem we need to solve it now in fact today there was a report by the u.n eep on the emissions gap which would demonstrate that nate that the national climate privilege uh pledges that have been made to this point would lead to global warming in the 2.7 degree c by 2 20 100. so this is a very pressing problem

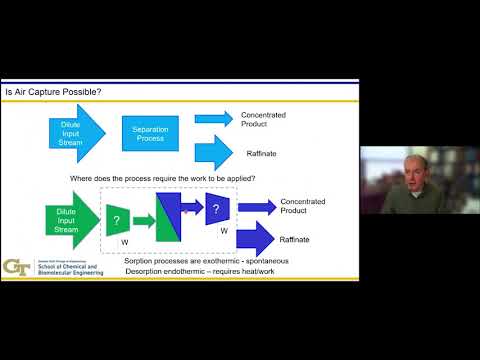

negative emissions technologies which are ways of pulling co2 out of the air so that we can reduce the concentration of co2 along with renewable energy are the answer to solving the problem of climate change in other words we have to be able to walk our climate our carbon footprint backwards and in this point i would say there is all of the above no one technology is going to solve this problem we're going to need a variety and one of those will be direct air capture direct air capture is a technological approach to removing co2 from the air and it's a very scalable negative emission technology and that's really what we're going to focus on today in this talk is really to explain how we can achieve direct air capture why it's feasible and the outlines of technologies to do so so direct air capture is today's manhattan project or moonshot so i'm sure we're all familiar with this uh keeling curve that shows the increase in co2 from 1960 here to the present day and if we look at today's concentration or the average of last month it was 413 parts per million a substantial maybe 150 ppm increase above in pre-industrial levels now if we were to make um a an estimate of what we might be able to achieve with renewable energy our current emissions today are about 40 giga tons of carbon dioxide per year and if we were able to hold that steady through 2040 which with growing population and growing gdp is is quite challenging in and of itself and then we were able to ramp that down to maybe a residual level of 10 gigatons per year by 2070 this is probably one of the most ambitious of the emissions targets that we have on the table today what would happen to our atmospheric co2 is it would rise from its current level of roughly 413 all the way up to 520 parts per million and that was one of the reasons i mo i mentioned that our current pledges which would lead to emissions profiles that would not actually match this but be higher would lead to global warming in the 2.7 degree range which is significantly above the targets of 1.5 and 2 is a more modest target so how do we walk our footprint backwards if we end up having a lot of co2 in the atmosphere we're going to have to have negative emissions technologies even if we're able to achieve fully 100 carbon or fossil free energy we still will need to bring this um concentration back down so i like to think of this as as the problem of stopping the flow and draining the tub so i have live in a victorian house and i actually have one of these clawfoot tubs and what we have to do is we have to work on capturing co2 from point sources but if we do so we only change the rate of accumulation we only change how fast the water is accumulating in the bathtub and if we accumulate too much we're definitely going to need negative emissions technologies which will remove co2 from the atmosphere and this was um outlined in a in a report from the national academy of of sciences and engineering where they looked at the negative emissions technologies and reliable sequestration and they did so across a variety of different technologies examining each of their scales and actually professor chris jones was one of the major authors on this study where he examined the topic of direct air capture along with other authors who examine things like mineralization of co2 the enhancement of art systems in the ocean the enhancement of afforestation and changes in agricultural practices if we take a look at sort of the emissions profiles that we've seen to this point what we would see is again this idea that maybe we could hold it flat and then bring it down or maybe if we went as business as usual we would have an even greater increase in our co2 and that to cut to essentially avoid having a large residual amount of co2 what we need to develop is a negative emissions technology that will bring down the emissions um from their um residual level and actually potentially create net negative emissions by the end of the century so we're going to do this through the conventional renewable energy use we'll do it by reducing the amount of emissions and then we will add our carbon removal technologies but the and then we will add does not mean that we should not start on on these technologies now if we had these technologies in place we would be able to potentially avoid some of the negative potential consequences of having high co2 levels in the middle of the century so the estimates it provided in the national academies report talk about having 10 gigatons per year removal by mid-century requiring 20 gigatons per year removal by the end of the century now if we think of this in terms of the industry that this would support this is 25 of the 2020 fossil fuel industry in 30 to 40 years and 50 percent of its size in 75 years so basically we're talking about creating a new industry that is of of a comparable size to our existing fossil fuel industry so that's a very significant opportunity for technological innovation so as i say let's look at the various different opportunities one is coastal blue carbon this has got low cost but ultimately the amount of shoreline that is suitable and the amount of of biomass we can accumulate on that shoreline is relatively limited on land we have the idea of afforestation which is relatively cheap and soil carbon enhancement which is also relatively cheap and can be scaled up to moderate levels we can also think of a combination of natural and technological systems such as biomass energy with carbon capture or storage which is referred to as bex now this particular technology again is going to use the biomass produce some energy from it and then sequester the co2 both in the form of of putting it into rock formations and also possibly by creating a biochar that is used again for soil enhancement the focus of our talk today will be direct air capture which removes co2 from the atmosphere using technological systems and again puts it down for sequestration the last remaining technology is the idea of accelerating the weathering of rocks by essentially creating greater surface area and this technology is is very nascent we don't really know how this will actually end up on unfolding but does have significant potential if it were to work out that it that it actually um can sustain the rates of capture that people would like it to if we grind the rocks up fine enough um so where have we come with direct air capture to this point so really the the original use of director capture technologies was for spacecrafts and submarines where you have enclosed environments where the co2 will simply build up if you don't remove it from the atmosphere one will remember the apollo 13 mission and and maybe the film where that in fact is a assembled by the team uh in in flight based on designs developed on the fly at nasa in 1999 one of the pioneers in this field klaus lachner proposed that large-scale direct air capture was feasible as a climate mitigation strategy and really since that time point it's really sort of bubbled around in the background and now eventually is starting to come forward as a possible technology so in 2008 to 2010 we had the first demonstrations and formation of companies of what is called temperature vacuum swing absorption processes and we'll come back to describe those in more detail as the talk unfolds and really there are three leading companies in this space carbon engineering global thermostat and kleinworks which is a european company which has engaged with microsoft or microsoft is engaged with them to actually buy some of the outputs of their of their direct air capture plants in 2008 2009 global thermostat and georgia tech married the technology that global thermostat was developing from a process perspective and absorbent technology that chris jones had actually developed here in 2011 there were the first sort of reviews of the direct air capture approach and this 2011 american physical society report was it was hugely influential basically it claimed that director capture of co2 with um amine sorbents using the conventional technology was about a thousand dollars a ton and unfortunately this report received a lot of press and actually a lot of people felt that this meant that the only way we were going to do direct air capture was to have costs of roughly that level but of course in fact if you think about inventing technologies that are different from the conventional technology there are ways to bring this cost down and that's something that we'll talk about as we go through this and in 2016 this comprehensive review of dac materials was published and this has a very very wide set of materials that actually are being used or have been used to explore for direct air capture so why is direct air capture possible so i'd like to take a moment to sort of talk about thermodynamics thermodynamics is possibly the foundational topic area that we need to be able to understand this and what it turns out is is that if we have a feed which has a certain concentration of co2 in it such as the 400 parts per million in the air or the 14 in of 10 to 14 in flue gases we can actually work out how much energy it takes to unmix a certain fraction of that the co2 with a certain purity and reject the raffinate or remaining stream if we look at this we actually find that this energy scales not with the concentration which is a factor of a thousand but really um actually scales logarithmically so that the amount of work required per mole of co2 is only 20 kilojoules relative to 10 kilojoules for post combustion capture so this gives us the possibility that in fact if we only double this that it means that we really essentially can solve this problem at this level and we don't have to rely on trying to do it from post combustion capture only and this is a very significant fact in the overall system analysis and design so if we have a dilute input stream and we want to design a separation process to produce a concentrated product what is really the the basic outline of what that process needs to do and the question we have to ask is where do we apply the work in this case so if we require to apply the work on the dilute input stream what will happen is we'll spend a lot of effort here and that will be extremely expensive and extremely energy intensive however if we can apply the minimum amount of work here such as for example pushing the air and actually have a spontaneous process which is exothermic that captures the co2 and then we put the work in on the desorption or removal of that co2 from the material then we essentially concentrate our work on a much smaller amount of mass than if we do it to the dilute input stream and this is really the difference between something like a direct air capture process and a mining process in mining you have to put the work in on the dilute input stream to remove the ore from the ground crush it up grind it to be able to get to the gold but in the case of direct air capture we can just move the air through a contactor and that can be our driving force to then essentially remove the co2 and then apply the work on the other side so do as little work as possible on the feed stream i.e move the fluid which we know as

air is relatively lagging in density and moves fairly easily we have windmills windmills in fact are roughly the same size as you need for a direct air capture system although often implemented with smaller spinning fans use the spontaneous exothermic process to absorb it and then apply the work or heat to remove the co2 to produce the concentrated product so with this as a rough outline of what we need to do i'm now going to move into just describing the the essential components of a direct air capture system before i turn it over to my colleague chris jones to talk about the more of the details so the first thing that we need is we need a material that will actually capture the co2 so basically what that comes down to is something that at 400 parts per million co2 in the in the gas stream will actually enable a certain amount of of co2 to be removed and then we must be able to vary the temperature or or some other property to essentially allow that co2 to be removed from that material at a different condition so that's the the fundamental thing we have to have is a material with a high capacity for co2 at low concentrations the second thing that we need to do is we need to avoid this high amount of work going in on the front end so what we need is we need something that has a very low pressure drop so that we don't have to put a lot of energy into the air to move it through the contactor and so that leads to the idea of having structured contactors with large porosity to allow the air to flow through them with low pressure drop but we also need to have contactors that have large surface area so that we can present this material to these co2 so that it can be captured and we've basically explored here monolith structures and hollow fibers we'll come back to what those are later and then lastly we have to design a cycle that will go between this absorption and desorption to be able to com apply this contactor to capture co2 and what we want to do is we want to have efficient absorption for long time periods and then relatively fast desorption so that we can then send our material back into our absorption this will allow us to keep the productivity of tons of co2 per meters cubed of of structured contactor per hour as high as possible okay with that i'll turn over to my colleague chris jones all right thank you matthew so um with that outline that you gave for what a typical process will look like i want to walk through five individual elements that i i believe are the key elements that have to be put in place to achieve a practical dac unit essentially recapping one slide for each of the key topics you introduced on the previous slide so here talking about designing a material that is selective to the very dilute co2 in the air versus nitrogen oxygen and water and all the other species that are there we can imagine doing that by designing a binding site that wants to selectively grab that co2 and the amine site shown in the center of the slide here is one where the chemistry for binding with co2 is outstanding and it leads to very very high selectivities and large uptakes as men manifested in the absorption isotherm on the left-hand side so on the left-hand side with this absorption isotherm the amount absorbed on the y-axis versus the concentration on the x-axis and what we see is that the isotherm shown in black for the chemisorbing amine material gives a very very high capacity even at these low con partial pressures that are corresponding to 400 parts per million co2 in contrast the conventional sorbents that have been used for a long time to capture co2 some things like zeolite 13x with the red isotherm which is a fizzy's orbit works very well at high concentrations and in fact is the basis for industrial gas separation processes today but is not very efficient at the low concentrations necessary for direct air capture so one of the first and counter-intuitive desires for this type of ultra dilute separation compared to existing gas separations is to use a chemisorbent with a strong binding energy that gives you that high selectivity at low partial pressures next slide so we'd like to then take that sorbent and coat it onto a structured contactor like you introduced previously so that you could get very high gas throughput with very very low energy expenditure and we're going to talk about that energy expenditure in the context of what we refer to as pressure drop in chemical engineering if you can minimize the pressure drop required for flowing gas you can minimize the amount of energy you have to put into the system so these low pressure drop high surface area contactors are ubiquitous today in the world and anyone who has a gasoline or diesel-powered car owns one of these because these are the contactors that exist in the catalytic converters of our cars and in our cars they're coated with precious metal catalysts that clean up the exhaust coming out of our cars and remove hydrocarbons and carbon monoxide what we would do for direct air capture is coat these with the type of amine materials or another suitable material that i showed on the previous slide and then we can get very very high gas velocities with very very low pressure drops so we can get pressure drops on the order of 0.02 pounds per square inch even with the gas velocity of 5 meters per second which is the wind velocity that you would experience on a stormy windy day outdoors minimizing this pressure drops important because based on a techno-economic analysis for a dac process that matthew and some other colleagues did earlier if not properly designed the cost for moving that air around can be as high as 30 or 40 percent but with a properly engineered system with low pressure drop you can reduce the cost of moving the air down to the order of 10 or 15 percent as shown on the right so next slide please so i said that we had to have a assortment that captures a lot of co2 and that's a representation of absorption thermodynamics we also want to be able to remove that co2 after we've captured it as quickly as possible so we'd like to adsorb and desorb very quickly recognizing that this process is cyclical alternating between absorption of co2 and then collection and desorption of co2 and um we can achieve that using these adsorbents on a monolithic contactor as shown on the bottom right hand side and what we would typically do referring to the plot on the left hand side which shows the total capacity normalized to 1 at the maximum as a function of time we wouldn't wait to completely fill the entire monolith rather we would stop early in the process at the blue line where you're exiting the linear regime where you could get 80 percent of the total achievable capacity in a reasonably short time and we show you here on the laboratory scale equipment that short time is on the order of hundred minutes that's relatively long for an absorption cycle and that's why we need to move out of a laboratory scale contactor and into a contactor like the monolith shown on the right hand side that's designed to give us very very high gas velocities on the order of 5 meters per second and if we do that we can shorten that cycle time from about 100 minutes down to about 15 minutes so getting a lot of air through the system is very important because as a figure of merit if we consider the desire to remove one ton of co2 and if we're going to remove 70 of the co2 that passes through our process we have to process 3 500 tons of air to get that one ton of co2 owing to the ultra dilute nature of air and this is why fast gas throughput through our process is critically important next slide please so as professor ralph indicated we essentially in some ways get the absorption of the co2 on the sorbent for free we design a selective sorbent shown in yellow that can selectively bind co2 shown in red and so it'll pass through and as soon as it hits the surface it'll stick to the surface and that happens spontaneously as long as we're efficiently moving the air through the process but we do have to put energy into desorbing and collecting that co2 that is the endothermic step the nice thing about a lot of the sorbents we have studied at georgia tech is they only require low temperature heat on the order of 60 to 120 degrees c uh which is considered waste heat and is uh available in some manufacturing processes for example so we can imagine bringing that heat in the system to liberate the co2 from those yellow absorbent spheres on next slide method by bringing in steam and the steam then would contact the sorbent and break the bonds between the co2 and the solvent producing a mixture of now instead of co2 and air now co2 and steam and if we cool that steam we can then drop out that liquid water as shown in blue giving us a nearly pure co2 stream in red that we can then use for sequestration or other uses and so we do have to put energy in to desorb this is where it's going to cost us some money and we want to design our process to minimize the amount of steam that we're going to use in this step next slide please and so we at georgia tech have been working for the past 10 years with a startup company there's about six to 12 startup companies in the world now that i'm aware of that are looking at room co2 removal from air working with global thermostat uh then we have uh built uh several generations of pilot or commercial scale equipment one generation shown on the left is from early 2011 2012 and menlo park california another one shown on the right is circa 2018 in huntsville alabama and so global thermostat uh this technology startup uh used to have their r d labs in atlanta uh co-located with us at georgia tech and the company's grown so quickly recently they've relocated to uh their own facilities in brighton colorado and i'll point out that i have done research with global thermostat for a long time and have a small financial interest in in the corp company and for that reason i'm required to share the conflict of interest statement at the bottom of this slide next slide please so if we consider putting these four steps together now in that process that has many individual steps the steps can be boiled down to two main steps on the left hand side an absorption step and a desorption step so that's one and four that he's pointing at now and in between we have some steps whereby we would evacuate the uh sorbent chamber uh bring the storm chamber chamber to pressure we would desorb and then finally cool the system after we've heated it up so that we can repeat that cycle and we've modeled the techno-economics of this type of process using a combination of experimental data as well as process models and we did it for a particular absorbent a metal organic framework film supported on a monolith contactor um we took experimental isotherms for absorption measured in my laboratory and used that to parameterize the model and then studied this removal of co2 from 400 ppm air at 25 relative humidity using a 40-minute cycle time and we calculate an energy of separation for what is effectively an nth plant so a mature plant that has moved significantly down the learning curve as having on the order of 0.15 megajoules per mole of co2 of energy use this type of process if we compare it to a point source capture so a flue gas capture where you're turning off the faucet in that tub rather than removing co2 from the tub we see that the total energy is only one to three times higher than it is for that higher concentration post-combustion solvent separation and so while it's 400 times more dilute in co2 concentration the energy penalty the excess energy penalty is actually quite small and that's one of the reasons why we believe that low-cost direct air capture will be possible in the future next slide so we have these five elements that i think are required for a practical process and every single one of these elements has been demonstrated on a laboratory scale by multiple different groups around the world at this point in time and what really needs to happen now is that these five elements need to be put together in a practical processes that then get deployed and operated at scale such that we can learn how to operate the processes more efficiently and effectively move down the learning curve so if we think back to solar energy in the 1980s it was very very expensive but then through deployments and learning uh altering the technology deploying and learning altering the technology etc we've moved down the learning curve to where solar energy is very cheap in many regions around the world today and we can imagine a future for a direct air capture that's quite similar next slide so two questions that i get quite often when i talk about this i'll just answer right now one is with regard to land area so can we actually do enough air capture to um to make a dent with the amount of space that we have on earth because we've heard about land limitations for other types of energy technologies in the past and so if we do a thought experiment we take that mid-century negative emission target of 10 gigatons per year and this and we asked the question what if we were to do all of that doing direct air capture well we don't think we want to do that we we want to do it with the whole suite of techniques but just for the thought experiment if we did it all with direct air capture using numbers from the startup companies that are out there how much land do the startup companies think would need to be devoted to get that 10 gigatons per year and the calculation works out to be about 150 000 square kilometers which is roughly the size of the state of georgia so i'm not arguing that we should take the state of georgia or any state and turn it into a dac um deployment zone but what i will argue is that amount of land somewhere on earth whether it be in five locations or five thousand locations is is not a show stopper we definitely have that amount of under utilized land around earth we could also imagine doing this on oil platforms and other locations actually in the sea and so we definitely have enough space enough land to deploy this technology second question that i commonly get is why don't we use natural systems like trees well one one answer to that is that as a species human beings have not demonstrated yet the ability to reforest we've only demonstrated that we can deforest on a global scale so until we can reforest on a global scale this will play a small part in the equation we would like to do as much of it as we can because it's natural and low cost however even if we were to ask rather if we were to ask the question how does a dac technology compared to a tree is a tree much better much worse so matthew did a nice calculation using literature data looking at a tree at the equator and how much co2 it removes as a function of the ground area that it occupies and he gets a number on the order of 20 micromoles per second per meter squared ground area and your typical dac process if you do the same calculation has a 25 times higher flux of co2 so if we design these uh mini chemical plants that take co2 out of the air we can do it more efficiently than a tree at the equator which means that it's a reasonable amount of efficiency using that as a benchmark next slide so matthew turning back over to you and then we'll do q and at the end thank you chris um so uh just to to talk a little bit about what we're doing here at georgia tech as chris has alluded to we have been involved in in dac technology and materials since about 2008 we have a large collection of faculty at georgia tech who work in the area of gas separations and particularly even in the area of co2 separations and we've recently established the dirac center which is a direct air capture center that is looking at essentially across the broad range of topics that are of interest or connect to direct air capture and we have a uh a strong infrastructure and history of academic industrial partnerships in this area i just want to highlight some of those aspects so the first question of course is why call it dirac well um paul dirac a very famous 20th century chemistry chemist and physicist actually articulated the thermodynamics of dilute mix mixture separation and that is of course the inspiration for why we think direct air capture is a potential technology that can play a role in climate change is because in fact dilute mixture separation theory uh points out that we only need a relatively modest increasing energy to separate a dilute mixture compared to a concentrated one so that's the one of the reasons why we we decided the center should have the name dirac if we look across who is in the center essentially it's a multi-disciplinary center that consists of folks like chris jones who work on materials design and fundamentals along with david scholl and ryan lively we have uh folks in physics and mechanical engineering who work on the on the fundamentals of contact and design and then there's myself along with my colleagues in process systems engineering fanny bukavala and joe scott who work in the area of process design and control and then we've also got an active uh set of individuals looking at utilization for example yong shen chen in civil engineering is looking at coupling direct air capture with uh co2 conversion using algae and then in the area of sequestration and in particular the seismic monitoring of sequestration we have and then in the policy and life cycle analysis assessment area we have three individuals working at looking at how to translate these technological advances into looking at how that should impact policy and also to look at some of the broader issues around life cycle assessment now i'd love to talk a little bit about the work in seismic monitoring of sequestration as that connects uh directly with some of the topic areas that microsoft has as a as a company so what do we need for low-cost seismic monitoring to make sure that our co2 stays in the ground where we put it and what we really need is we need some open transparent system that can enable us to lower the risk to society and those risks come both in terms of where we should locate it to start with and then making sure once we've put the co2 in the ground that it stays there so basically seismic monitoring technology can mitigate hazards and account for the mass of injected co2 so that not only can we make sure it's there safely but we can make sure we know exactly how much we put there so the approach here is to create an open platform and it's modeled over after the open ai type of architecture and what we want to do is use this open platform to lower the cost of development to deploy this monitoring system avoid the replication by multiple governments and multiple agencies to come up with this monitoring capability so that they can simply reuse the the capability that's been created and accelerate the innovation around this by creating the access to the code data and high performance computing now the type of questions we want to answer are how often do we need to monitor by shooting seismic uh images to to figure out how the long-term risks can be mitigated and when we can and how can we adapt as the as the sequestration project matures in other words how often do we need to to do this can we in fact lower the rate once we've established how well the uh the the system is sealed and what is the seismic detectability of co2 plumes can we actually observe movement of co2 in the rocks should we need to so for example the density of the of the sites where we have to take the seismic measurements and also how much we have to replicate the surveys to be sure that we have a real effect and then what are the scenarios under which we can feasibly acquire the information so to outline this in a bit more detail what we start with is a is a seismic model which which represents the rock in terms of the wave speed and the density of the uh the wave speed of the of the seismic measurement and the density of the rock and then we have to convert those measurements into the porosity and permeability of the rock to be able to understand for example how co2 will move inside this particular set of rock formations and what we do then is a flow dynamics simulation based on the permeability and porosity of the rocks and here you can see where a situation where co2 in this uh area here actually finds a way to break through a crack or or a fissure in the in the system and actually release into the upper rock layer and so the question is is could we monitor and detect this type of behavior in this system so what we can do then is take the flows and convert those back to the changes in the in the rock and actually be able to figure out using a seismic model how that would uh how that would evolve and then we can take seismic measurements to essentially recalibrate to go back from our flow fields back to the density and wave speed of the of the system by essentially creating time analyses of the uh of the rock by um seismic measurement and that seismic measurement can then reveal not only the structure of the system but also what are the changes that have occurred and you can see here that this is a situation where the change is being is detectable through these seismic measurements and so this enables us then to build this open platform of seismic monitoring that enables us to de-risk the sequestration of co2 as we move forward and this is the type of activity that the dirac center wants to support so that we can actually complete the supply chain from materials development and process development through to the monitoring of the of the sequestered co2 so um here are the key messages again i hope you uh have uh have absorbed or had the opportunity to absorb some of them history shows that we can respond in rapid focused ways and we believe that director capture is the next one in this line of of projects that we've undertaken as humanity and then we believe that we need to undertake this because it's the defining challenge of our current era and we have to tackle it or we may well end up in a situation that is irretrievable with respect to some aspects of society we believe that negative emissions technology along with renewable energy are the answer but we need all of the above we need a variety of these scalable negative emissions technologies but the direct capture will play a substantial role in this and i hope that the last thing that we've managed to do is to convince you that admins orbits supported on these types of structured contactors offer a practical scalable approach to dac so as long as orbit lifetimes are sufficiently robust now back to chris all right so we'll finish here and if you're interested in this area and it's a new area to you i want to encourage you to consider attending this conference on the fundamentals of adsorption in broomfield colorado next may this is the largest absorption separations conference that occurs on a three-year cycle and a major emphasis this year will be on co2 removal from point sources as well as from the air and given that several of the startup companies in this space are also located in colorado we anticipate opportunities to see direct air capture facilities as part of this conference so with that we're very happy to have the opportunity to share uh what's going on in this space uh globally as well as at georgia tech and at this point i think we're ready for questions great um thank you so much that was an incredibly valuable insight into i think the fundamental issues to be solved around direct air capture and then zooming out to the scale required you know on the face of it 152 000 square kilometers does not sound insurmountable so that's promising um so i'd like to introduce philip at this point to start with the q a and then we'll um interleave uh one-on-one and through the q a for as long as we can yes um thanks so much connor i encourage the audience to keep sending the questions we have quite a few in the chat so i'll just kind of work my way through it um based on upvotes so one question that that came up was what happens with the co2 after it's uh captured so we know from industrial ccs plans that they usually they compress the co2 and they ship it away or they put it in a pipeline but presumably you cannot build a pipeline to every individual direct air capture plant so i'll take that one so we do believe that sequestration will be something you'll have to do with direct air capture but one of the advantages of direct air capture is is that you can potentially position the direct air capture technology directly above the co2 sequestration site so if you were to do sequestration on land you could certainly think about locating the um the dac plant either on top of or very close to the place where you wish to sequester it now if you believe that offshore sequestration is going to be the uh the approach um unfortunately probably building 150 000 square kilometers of direct air capture above the ocean is probably not something we want to do but you could imagine again locating the direct air capture very close to the uh coast and then using uh pipelines to to move the co2 to ocean um bed uh capture uh locations so we believe that capture and and sequestration will be a valuable part of this but we also believe that this is the situation where co2 capture at the scale of maybe a few a hundred thousand kilotons might be something that we could actually use and convert uh profitably profitably into other chemicals for example so coupling it with renewably produced hydrogen to produce um fuels and chemicals is certainly another alternative that is being looked at chris did you have any add anything to that so it would make sense to kind of cluster the i guess the direct air capture plans you wouldn't just have like an individual vice in the landscape somewhere it would make sense to kind of put them together i guess into clusters yeah i mean putting putting them at the level of 1 000 say tons a year or or smaller really implies that you have a use for the co2 and you find that if you examine the amount we have to capture we rapidly run out of uses of co2 at that scale there's only a certain amount of fizzy drinks you can you can you can have and and that really just doesn't scale with the problem of co2 capture for for climate change great and i'd love to hear so this was a question that came in but i'm personally curious too so what role can a technology partner like microsoft play in direct air capture and where can technologies like cloud computing ai and machine learning help um so i can i can step in i'm the process modeling and simulation person and so i would say that one of the things that we're definitely going to need to do as we move forward is is understand how high performance computing can help us design these systems one of the unanswered questions at the moment is exactly how arrays of contactors will behave if we set them up so you can imagine flowing co2 past an array of contactors and the co2 will be removed from the air how quickly does it recover on the far side of the contactors how do we space the contactors on the landscape how do specific features of the landscape affect the performance of this and this will require a substantial computing power to be able to work out those kinds of ideas also we want to design more effective contactors and although we have the models necessary to do that i'm carrying out the the sort of computational fluid dynamics simulations coupled with porous material behaviors is actually quite uh compute consuming did you have anything to add to that chris just to re-emphasize that on the uh sequestration and monitoring side where felix is working is very very well aligned with um the needs and the opportunities in the high performance computing space okay yeah that makes a lot of sense i think um then we have another question that says um i'm curious about the amount of air that has to be moved could the farm of these dac systems cause localized weather phenomena and i guess that's also a question where maybe uh the simulation aspect can come in again there you do some kind of forecasting simulation to actually model this but yeah so the answer is yes well the answer is we don't know the answer to that question and it's something that we would like to examine again to de-risk the deployment of direct air capture i mean to take a classic example we really at the moment don't understand how for example uh pollination all right when we when we have trees the in the in the spring releasing pollen if these were near direct air capture systems we don't really understand how the pollen might interact with our direct air capture um changing its performance uh one of the things we're looking at at the moment is how does air temperature affect the performance of these systems do we need different capture materials different device designs if we were trying to do this for example on antarctica as opposed to doing it in florida so these are these are all questions that we would like to analyze using modeling and simulation with the limited lab experiments that people like chris are able to carry out because you know building these systems and then going oops that didn't work it's probably not a great idea great so there's a question on economics as well um i know from reading through some of your papers before this that you've looked in depth at the economics of direct air capture also and so the specific question is where does the misconception of the thousand dollars a ton come from and then it would be great to hear any commentary you have on the evolving economics with reference to the increasing carbon prices um in places like canada and the eu and how you see that stacking up as the technology advances and hopefully costs come down why don't you take that one chris sure so um with regard to the components of the cost so the original estimate of say a thousand dollars a ton uh was gain was achieved by taking a process that was designed and commercialized for high concentrations and applying it to low concentrations of gas and i think the economic estimate for that type of process was a reasonable estimate so what what the startup companies have done in the in the interim is to design processes that are specifically targeted to the unique challenge of the unique of the low concentration gas that is that is air and what that does is it reduces the uh cost of the contactor um it reduces the cycle time um and it minimizes the uh to the extent possible the amount of energy that's used in that second step the the endothermic desorption step which is a high operational cost step and then finally by having a system that's designed for these ultra dilute mixtures you can thereby reduce the capital cost by making the cycles be as short as possible so that you can deploy your equipment and cycle it as quickly as possible and all of those individual elements go into creating processes that can be i think today if you talk to the startup companies the the technologies can be you know 400 to 800 a ton and the idea by using the uh learning curve models that exist in other fields you can project these costs over a period of 10 or 20 or 30 years dropping down to the vicinity of a hundred dollars a ton or or maybe lower um and so what was the second aspect of that question again it was about uh and economics like with respect to say the existing carbon prices in canada which i think around like 60 to 80 a ton an eu i think something similar all right so yeah so the fundamental thing that's different from uh the previous example that i gave about learning curves and cost reductions with with regard to solar is that solar produces a product that everybody on earth wants to buy every single human being on earth wants to buy energy and right now the product of negative emissions of co2 is not one where markets are well developed and so for a long time you saw a stall in the development of these startup companies and and these technologies and i feel like the word the world's shifted seismically around 2018 in the united states with the uh consideration of negative emissions for uh credits in the california low carbon fuel standard which typically has uh trading on the order of 100 to 200 per ton uh and then 45 q is the federal tax credit at 50 a ton and then you have carbon markets whether they be in canada or parts of europe that are also bringing in ways to monetize that carbon and those things happening quasi simultaneously really has increased substantially the momentum for new ventures and new companies uh moving into this space because there now becomes clearer paths to try to monetize the technology in the early stages when it's still not that efficient which is critical getting the technologies down the learning curve to the point where costs are now coming down enough that you can imagine widespread global monetizing of these technologies via hopefully what will be at some point in time global costs on carbon um thank you so there was two questions relating to the location of capture plans and i'll combine those questions i guess into a single one so one ques uh the question is um does it make sense more sense to cluster them or do would you get in a similar i guess effect if you more spread them out evenly and are there some geographical regions that lend themselves more to the installation of these capture plans than others so i i guess i'll jump at that first um i think that uh taking a um a bird's eye view the nice thing about co2 removal from the air compared to conventional post-combustion capture at point sources is that your feedstock the air is in principle the same from a carbon perspective everywhere on earth so that means that large installations versus scattered installations that's a that's a systems optimization that's the area that matthew works on and he can talk about that in a moment whereby i think any of the solutions uh in principle are feasible because of the fact that co2 is the same everywhere there are however there is there is also um the difference in climates in different locations and that's something that we at georgia tech have started to think about trying to exploit so for example when you're capturing co2 if you co-capture a lot of water that comes with an additional burden to process that water from an energy perspective and so if you're operating in louisiana or in florida you have to have a process that's suitable to to manage that high humidity which is going to be different from if you're operating in a more arid climate in arizona or eastern washington or something like that and furthermore you can imagine also temperature variations right so in florida or louisiana the amount of water the air can hold is much higher than in montana or north dakota as a consequence of the change in the absolute humidity as a function of temperature and so we think that the varying climates could lead to a future where we imagine 20 years from now there might be five or ten different technologies that also take co2 out of the air but are specifically optimized for operating in a particular climate regime where maybe the florida process wouldn't look very good in arizona and the arizona process might not work in massachusetts for example okay look um maybe a bit of a follow-up question there too um so one aspect i read about this claimworks facility that they're building that they built it in iceland if i remember correctly because they wanted to use some of the passive heat from uh geothermal energy to to do some of that strip it or to use it in the stripping process um so i thought that was very interesting i guess a lot of people have the question there are other sources of heat or energy um where you can kind of take advantage of that i think some people mentioned oh data center generates a lot of heat i guess it's probably not enough for direct egg capture since you mentioned something 60 to 120 degrees celsius i guess the data centers are a little bit below that but are there other maybe possibilities to take advantage of existing energy sources so so let me just step in and say that we have actually thought about data center integration and the answer is is that um what you can do is you can circulate a uh uh organic rankine fluid uh through the data center to cool it and then with uh with a vapor compression cycle you can actually upgrade that heat into the range necessary to make direct air capture work so it's a little bit harder but basically think about a heat pump you can effectively use a heat pump because the amount of temperature you have to raise system buy is not so much that you can't use something like a heat pump so a heat will be effective in the case of of using it for example coupled to uh to data centers so so we have actually considered that that particular source of heat but again you recognize that the amount of heat required here is is significant even for modest scale implementations and again is is do we have the space uh to to build a lot of direct air capture contactors near data centers that i don't know about but if it's possible certainly that that source of low-grade heat can be upgraded using heat pumps to make this kind of system work yeah there's a lot of low-grade heat and manufacturing processes that you can imagine using but if you're going to do that you're also going back to a previous question envisioning a future where you have a lot of smaller scale installation installations that are scattered around because the economics might tell you that using that heat is valuable but then you've got to transport the co2 as a product or you might model and say that co-locating by the sequestration site and minimizing transportation of co2 outweighs the advantage of having a little bit of free heat with these distributed type systems and this is why sort of a systems-wide optimization is needed the other the other approach would be and this has been has been discussed is you know now you've captured the co2 and now maybe you can bring in um either a a methane or something like that um basically be able to capture the co2 coming off the methane in the same way or do something similar and combine the hydrogen that you're getting there or make the hydrogen renewably from a fuel cell i mean from a from an electrolysis cell and take that hydrogen and combine it with the co2 and actually make uh locally fuels or chemicals i think that turns out to be very very energy intensive in compared to just capturing the co2 itself but it would allow you to move to an energy system that was much more distributed in terms of its of its production of liquid fuels that might be useful um ways of cutting down uh use or or removal of fossil fuels from the ground uh as some intermediate strategy to generate uh useful products great and perhaps we could finish with one final question there are a few questions that have come up in the chat related to portfolio of technologies and standardization and i'd love to put a microsoft specific slant on that and you mentioned earlier that microsoft have some existing relationships with climb works and the wider um fact that microsoft have a carbon negative goal by 2030 so we are out in the market today purchasing carbon removal and so i'd love to hear any advice that you have from a technology point of view as to how that microsoft carbon removal team could direct their um purchases to have the most positive impact on the technology and to drive it forward and then and whether the different offerings like the energy the major energy and companies enhancing carbon removal like for example eggs and mobile are they all using the same technologies or are they using different ones why don't you have a go at that one chris okay well i'll i'll tackle the the latter question uh first and then uh have the first question go back to matthew so um in addition to the startup companies that are in the space there are a lot of what i'll call conventional energy companies whose core technical expertise within their organization is very well aligned to remove co2 from dilute mixtures so if you're talking about a major chemical company a major oil company major gas processing company all of these companies have had have the expertise in order to work on this topic but they haven't necessarily deployed that expertise in the past to deal with these ultra dilute type separations so what you see them doing now is pivoting reorganizing developing alliances to deploy those those experts on this ultra dilute challenge and um i know that uh in some cases these large energy companies are also you know partnering with startup companies and trying to find synergy there as well so i think there's a lot of activity in this space they're not all using the same approaches for sure there's a there's a fairly good variety of different approaches but there's i would say a handful approaches now that i think are most attractive for near-term and medium-term deployments and so that's why you see some some companies clustering around particular approaches because they they might be perceived to be more quickly deployable but i think there's also plenty of room for this long-term problem to look for the wild and crazy out there ideas as well and matthew do you want to tell microsoft how they should invest their uh their negative admissions dollars well so i'm going to come back to my statement all of the above i think it's really important that we support a portfolio of technologies uh some of which will be cheaper and nearer term and some of which will be more expensive and longer term uh we do need to to start buying direct air capture so that we can start moving down that learning curve and i would applaud microsoft for stepping up and buying um some of the product from from climb works at high dollar numbers that's i think that's really really important that we do that um i think the the lower cost options are are important i would my one concern about some of the lower cost options is is of course the permanency of the uh of the storage um that is one of the things that you know along with seismic monitoring to be able to figure out that it stays in the in the ground is one of the advantages of doing direct co2 capture and and sequestration is is that you do have a pretty good guarantee that it will stay there whereas enhancing natural systems or or growing more trees one one does have the concern that that might not persist over over geological time scales necessary to really remove the co2 but i think it's in all of the above and i applaud the idea of going for a portfolio that supports multiple different approaches at multiple different scales great thank you and why don't we hand over to philip given the time perhaps we could wrap up there so i want to thank the speakers again uh thanks everybody for attending this was amazing talk super informative um yeah and i know we already have been over time um i know this may be the leftover questions i made for those via email and yeah thanks again for the speakers and um i think we do have an upcoming rfi lecture series talk um please join us on november 11th for um adversarial models from options pricing to trade execution and this is a talk that's going to be given by chaitanya bandi uh from the kellett school of management at northwestern university so that would be another amazing talk please join us for that and thanks again

2021-12-02 18:43