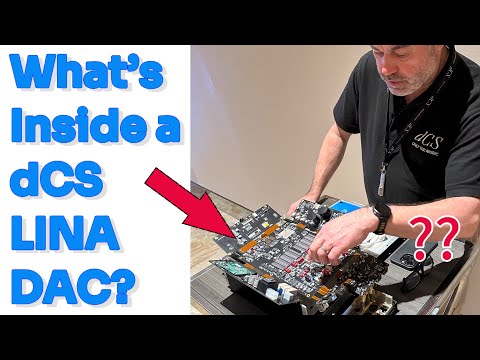

What’s Inside the $13,000 dCS LINA DAC?

The circuit board's really sharp and if i don't wear a glove I'll cut myself it's not that it's like very delicate or I'm going to do any magic or anything like that no no no it's not for esd this doesn't have a power inlet so we're we're we're all we're all good okay ready you want to get bring come a bit nearer so um I thought I'd just um do a bit of a reveal and show you what's inside a dCS Lina DAC so this is my constant travel companion Lina uh she goes with me all over the world and this is what she looks like inside and there were a couple of things about the way Lina is made that I wanted to show you guys So first thing I wanted to show you is that most of the electronics that you'll see here at this show the chassis are boxes and what I mean by a box is something that's made out of flat plates okay or or or maybe folded plates so the chassis of the leaner is mil from solid billets so this is the bottom plate this started life as a billet of aluminium this thick and then it's been milled out to make this shape you can see the the milling marks here but you can't actually feel them if you it's completely flat but but you can see where the milling machine has has gone around okay now one of the so this has a number of of benefits of using this this uh way of constructing firstly you can hear this has a very very low resonant frequency if you make the chassis from flat plates the resonant frequency is is much higher so this is much more inert um the second thing is we can make it exactly the shape we wanted to so in this case you imagine this is upside down so the circuit board is sort of folding around the transformer here and the transformer is a potential source of noise both mechanical and electromagnetic noise so we want to move the transformer as far from the circuit board as we can so what we've done is instead of having feet screwed to the outside we've actually used the the milled construction to drop the floor where we mount the transformer which brings the transformer further away from the circuitry that that can be affected by it um this part of the circuit board is the output uh sorry the uh power supply so this is all the regulators and everything uh that take the uh the voltage from the transformer and smooth it out into really nice uh dc um that can generate quite a lot of heat so what we've done is we've mounted it directly against the chassis which is the mil chassis so it's quite thick to it's probably 3-4 mm thick and this whole this whole part of the chassis which is again milled from one solid billet this is all heat sink the entire chassis is a heat sink so we don't need any discrete or external heat sinks the whole of the chassis is is a heat sink I was wondering why you didn't shut the contact another advantage of this construction let's say uh we wanted something we had something this side that was very sensitive to uh electromagnetic interference and we wanted to put a shield in between them well instead of putting a a separate part in we can just mill a wall into the case and put that the other side of the of the wall so we can basically configure the chassis around the needs of the of the circuit if you look at this end plate here spacers which you would normally need to mount a circuit board in a in a box chassis these are milled into the end piece not only milled in but they're pre-drilled and they're pre-tapped so i can put a bolt in i don't need a nut i just have the bolt and i put it directly into the chassis so you can see all the mounting points all the screw holes they're all built into the chassis so the number of pieces i need in this construction is much lower than if I'm screwing plates together if i if i have two plates like this and i need to put a bracket to hold them together and then i need two screws on each bracket and if i want to mount a circuit board i need spacers which are like little turrets that i put the circuit board on and a bolt goes through and a nut on the other end here i can just mill the spacers into the into the chassis so that's about the chassis if we look at the circuit board so sharp so looking at this you might think that this is six separate circuit boards this is one circuit board this is called a flex rigid circuit board so basically this is a 12 layer board so there are 12 layers of conductors inside this and then there's this solid substrate what this manufacturing technique does is it removes the substrate around these edges and then the 12 layers of of copper traces are encapsulated in a flexible resin which means that the whole board can now bend so we can take a 30 cm by 50 cm board and we can fold it up and put it inside a shoe box the other benefit of this for from a packaging point of view is we can take advantage of these features like i can i can fold a a heat generating component i can fold it up to a thick bit of chassis and mount it directly so that it can use it as a heat sink or if i if this is very sensitive to noise i can fold it down behind a wall that I've built into my chassis so the combination of the flex rigid board and the milled construction gives you really really interesting packaging alternatives the the second area where flex rigid gives us enormous benefits is electrically so anytime you have two um conductors meeting you get an impedance mismatch between the the two the two materials because this is one piece every one of those 12 planes is completely uniform impedance which means electrically this board behaves nearly perfectly it's it behaves just like the spice model there there are no impedance mismatches because we have two wires connecting together or we have a ribbon connector how many layers 12 layers 12 this ribbon cable is actually is 12 layers of conductor inside a piece of resin it's already inside so it's not additionally solder on or anything no no this is one board just one board it was ribbon cable yeah exactly that's that's why I'm explaining it because when i when i saw this i thought these are ribbon cables but it it's it's way clever so a ribbon cable if if any of you have seen a ribbon cable close up a ribbon cable connector uh consists of pins and like a spring that that goes down on them so the spring can fatigue and it grips less loosely it can there can be gaps the pin can get oxidized or there can be dirt so anytime you have a physical connector you have a potential point of failure with the flex rigid construction we have so many less potential points of failure because this entire board can be tested as one unit we don't have six boards that we need to then assemble together and then retest system test so this can be this can be tested by the board manufacturer and when it's delivered to us we know 100% that it's it's working so the interesting the most interesting thing from my perspective is the flex rigid construction especially with this size of board there's there are very very few board manufacturers who have the machines that can stuff a flex rigid board this this big it's very specialized it's very new I think we're the only audio company that's using flex rigid at this point so this is a much more expensive way of of building a board than if we use separate boards the milled construction from solid is much more expensive than using flat plates and and bolting them together but with this construction we can use one bolt size with one torque setting we need no spacers we need no nuts cuz they're all built in and the time that we save assembling the product the the our previous generation of products took 3 days to assemble and test this takes 15 minutes to assemble and test and the saving on the human costs more than offset the additional costs of the components so by making it in a much more sophisticated way that's uses much more expensive components we've actually made the product cheaper how much is this this Lina DAC is 20,500 Sing this is our entry level product if you have any problem with one of the connector this is not a connector it's just a trace yeah flexible pcb right before yeah so if you have one problem is cracked or something then you have to throw it it can't be replaced no but but we the failure rate with these boards on once they've been tested with the with the the by the manufacturer i don't we've been selling this product for i think 2 and a half years i don't think we've ever had a failure they are incredibly reliable because there is just nothing to go wrong is a new technology yeah it's really exciting technology so happy to answer questions that was what i wanted to to show you the the milled construction the flex rigid boards and what you get when you combine them is really really powerful really exciting these are resistors right yeah so this is these this is actually the DAC oh so it's r2r deck it's an r2r DAC so uh 48 uh resistors per channel and then the the the the the uh dCS uh kind of magic if you like our our proprietary um kind of yeah uh advantage um or uniqueness is the way we use these resistors we basically so we we have 48 per channel but the signal that's being passed through them is upsampled to 5bit 2.8 8 mhz so for maximum signal we're going to light up five of these resistors the reason that we have 48 per channel is because we want to move the signal around more or less randomly so that we're distributing the current statistically over time distributing it evenly among these resistors and so we have uh like a brain which is for every sample is deciding which and how many resistors to light up that's running in this fpga and the algorithm is called the mapper and this is like the brains of the of the ring deck every single sample is being sent to a different combination of these resistors which basically means that signal correlated distortion is being turned into non-signal correlated noise that's the job of the mapper and rather like the the background noise in this corridor your brain is able to filter it out very easily you all you're focusing on my voice my voice is the signal and the noise is easy to ignore whereas if i if i introduce distortion into my voice by having my nose that's very difficult to ignore your brain can't filter that out but all the background noise because it's not correlated to my signal it's very easy to to filter out so we're trying to and noise can be mathematically noise shaped you can kind of move it around hide it in the corner where nobody's going to notice a shield or that is a shield around the it's a toro so this is just a shield sd card is this sd card is it yeah it's a micro sd yeah it's a micro sd um so that's that's the um no the it could be actually for the firmware though i mean the firmware update yeah probably update yeah come to the update 16 has been famous you know you guys can always update your normal deck you can send it for effects update and all the things then this guy i think basically can't right yeah since on the well because it's flex rigid yeah so you can't upgrade the deck no exactly because the the deck is this part here the apex board is essentially replacing that part this is half apex so this i i hope buying this because all the other product was upgraded yeah yeah but so waiting for this guy to go full effect yeah so well it's it it's halfway there because the both this Lina Dac and the Apex upgrade were results of the r&d work done on the vess so vess is you know the the project the project the project is moving along and then the first branch eventually becomes Lina the second branch becomes apex so the first branch already has some of the r&d that went into apex but not all of it cuz apex came afterwards investment here so i was thinking wait for you guys to go full apex or you know yeah maybe we will you mean because it can be upgraded your the other day all can it can be it can be we just need to swap the whole board yeah yeah expensiveness your i saw that your rosina and all the other deck can be upgraded you know with at least partial not no but as i say there are there are like 16 good reasons why we went with flex rigid construction and you know it it's like everything it has this great everything has has you know advantages and disadvantages this is less modular but in terms of the improved yield we we get no test failures uh we get very very you know so far i don't think we've had a single one that needed to come back to the the factory so it's it you know it's it's very resistant to failures uh gives us the packaging advantages um the ability to to utilize the mil construction much more flexibly to it and and you know and the electrical advantages of common impedance the uniform impedance so it's half effect that some of the technology more or less half those or is it just uh no the so the clocks this is the dac so the clocks in the dac are both vcxo because we have vcxo voltage control so in the master clock we have one ocxo and one vcxo i i always curious you know isn't a better clock in a deck better than external clock i i just sometimes i don't get it no so the excellent question um and the answer is the the so the the clocks are like a conductor in an orchestra yeah they're beating the time he's the last guy yeah he's he's he's yeah he he is governing him this is the mapper he's making the decisions which resistors and he is telling him now now now now these clocks always manage the digital to analog conversion always even if you have a master clock that's why i say i i somehow i this is a three-piece design you know i was considering this set for a long time so it's three piece design i always don't get it if the tech clock is good enough why do we need a master so the DAC so so the the let me answer so the the clock in the DAC is as absolutely as good as we can make it but it has an fpga next to it running at six mhz okay it has a transformer it has all this circuitry around it in the master clock we we have been able to scale down the environment to only what's needed for the clock crystals so even if we use the same crystals in the master clock we don't we use one ocxo and then one vcxo but it's the same as as this vcxo it's exactly the same crystal but the environment that it's running in is so much better yeah there's an envir advantage here but then the cable loss no i mean clock it's it's a ttl signal we can we can we we can recover it perfectly with the plll the fact is it's a it's a less jittery clock we're not sending the clock signal over an audio interface it's not embedded in in in audio we're just sending us ttl square one of these rj45 connector right i mean you no it's it goes through the bnc's oh the bnc's yeah just a 75 ohm bm bnc so the the the fact the the i mean you can hear the improvement i can i can i can play upstairs they have the master clock in the in the in the i hear it i hear it so start playing a track yes with with the with the with the master clock and then just pull the cable out in the middle of the track and then put it back in i do this at shows and you can immediately hear the difference it's making the amazing part that technically is very hard to understand yeah but the main thing to understand is these clocks are always the ones in charge the master clock just puts a hand on the shoulder and just steadies these clocks these clocks your design is different because the rest of people design they just cut off these two clock and then they use the external clock i i don't think you can do that i i i can't speak for other people's designs what they do is that they also using the master cloth they do a pl or whatever they do it and then after that they it's 10 10 mega then they come in and then they just you know just drive the thing yeah people who do that we've been doing clocking for 30 years you guys there is a chance that we ask you this question because you are here so now i learned something you do something different but trust me these clocks are always in charge yeah you guys do something different than than than your clockwork and these clocks are very very accurate clocks but there you know there is so much going on in this chassis that there will be a little little bit of emi which will be affecting them which we can eliminate in the in the master clock just because it's in its own chassis you know clock crystals are incredibly sensitive to mechanical vibration temperature fluctuations emi they're sensitive to everything they're like they're like the most sensitive woman you've ever met they break out crying at the least least thing yeah well and temperature i mean the the resonant frequency of the crystal changes for every you know tenth of a degree uh dcs is always so expensive it's also a mystery to every one of us that we never got a chance to try it you know so this is the most basic entrance level thing that at least i dare to ask question so you're saying that you your the master clock and this clock you have some secretary to take in the master clock and with this as a reference still as a reference and do some compensation to correct exactly that's why so that's why interesting so that's why we use vcxos vcxo stands for voltage controlled crystal oscillator so you can change the resonant frequency you can tune the resonant frequency of this crystal by changing the voltage if we used ocxos's here we would we wouldn't be able to use a master clock because they're always at the same frequency because they're tuned by temperature and they have a they have a resistor inside them which which has something there you go around exactly so the voltage that is driving these is what's tuned by the master plan that is different from other people other people just don't do it i thought it was obvious no they don't yeah they just i don't know whether they yeah most of them they just chop off the and then just take the external clock and then they go through some repro and then just generate back the the the the master clock mclk or or the the eck something you just general back yeah it's different

2025-06-01 21:40