ASAP Webinar "Introduction into Aircraft Structures Design" with Andrija Ekmedzic

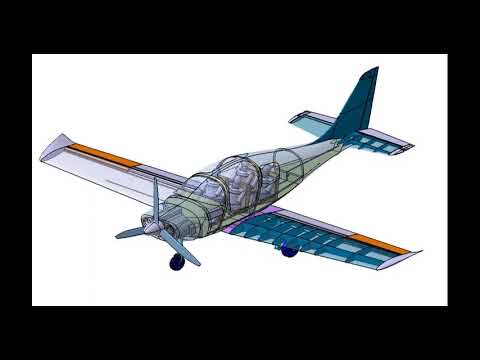

yeah okay okay yeah we can start in English then we can start in English in English then hello everybody and welcome to the new ASAP webinar uh which will be held by Andrea the PHD engineer and the PHD on faculty on aerospace engineering in Belgrade University and the theme of this webinar will be the introduction into aircraft structure Sandra please can you introduce yourself uh thank you very much we have decided to hold this webinar in English language in order to make this content available for international audience I would like to just quickly introduce myself and if you like to know more about me you can find you can Google me online or maybe on LinkedIn this is the best description of my professional career by now I have worked more than 20 years as an engineer in aviation aeronautical industry this is mainly in the design and manufacturing of various aircraft I spent around five and a half years in Utva aircraft Factory in Serbia which is responsible for manufacturing of the Piston powered trainer aircraft general aviation and then most notably I spent around eight years working for Airbus in the UK which is part of the largest and best civil aircraft manufacturing in the world I worked on all of the Airbus aircraft except military but I spend most of my time on Airbus A350 which is the most modern um wide body civil aircraft in in the US today and in many ways most modern and comprehensive aircraft in the world today and after this I formed my own company which is mainly involved in aircraft tooling but from time to time we do a little bit of engineering so in last couple of years I was involved working with CT engineering on uh wing of tomorrow on a folding wingtip for example this is a research project of the Airbus then with FACC on design of wing tips for Airbus aircraft and also for the Dassault Jets and most recently I spent nine months working on Lilium groundbreaking aircraft which is part of this new wave of electrical VTOLs which are thought to revolutionize the industry also very important is that I finished all my education on University of Belgrade where I got my PhD in 2008 so this is like the nutshell of my career but let's not talk about me let's jump directly to this content for which I'm sure you're very very eager to hear and maybe later on some people can rewind this content later on and maybe just reinforce what they heard initially so such short contents or what I'm about to say is I would like to explain during this content General task of the structural engineer which would cover a material selection structural requirements simplified structural layout of wings simplified structural layout fuselage I will talk a little bit about Shear Center we'll talk a little bit about Wing sizing and fuselage size uh just to let you know feel free to stop me anytime during this talk and if you want to ask question in Serbian uh feel free and I'll I'll try to answer in English so but you you can you can ask you can ask in Serbian not feel obliged to to ask questions in English okay the ends of this course is to give you an understanding of many drivers in structural design of the aircraft which includes the understanding of influence of material selection on aircraft design and to give listeners simplified explanation of the role of main wing and fuselage parts so what you will learn as a listener so on the completion of this course you will be able to define a proper material for the aircraft part of your need explain the most common aircraft manufacturing technologies. Explain structural drivers and durability drivers durability is sub part of structural drivers. Explain particular risk drivers then explain Wing sizing drivers and role of wing and Main of wing main parts and similar for fuselage you will learn fuselage main sizing drives and role of the main fuselage parts but first together it's rolling let's jump to vocabulary so main words in English that you need to know so we have a word driver which is a requirement in Serbian this would be this active uh structural driver is what it takes for parts not to crack this is a very very simple and plain terms durability driver Is What It Takes for parts not to crack over time so durability speaks about resistance of parts during period of time and particular risks talks about some special events for example like bird strike so this this is the example of of Wing crack so when we say structural drivers this is obviously an example in which structural drivers failed for whatever reasons maybe the loads were not correct or maybe the wing was too weak never mind we don't know but this this is the example of structural driver and this is this is the example of durability driver what it takes for parts not to crack over time so this this is actually a durability test which is testing Parts uh uh for uh resistance uh to loads over time so so I would like to ask you to to join me in any of you and if if no one if no one raises a hand I would like to ask closer and maybe Lydia to contribute uh can you can you guess which aircraft could this beep for example what they're confusing do we see on the photo seven five seven seven triple seven maybe no no no but you're close it's my my favorite airplane you figure it out right now I'm the Boeing guys no problem no no no it was very good guess okay so main words that you need to know are connected to the instructional parts we have Link skin or Wing cover and in Serbian language we call this o platter next verse that you need to know is being Spar which is one of the most important structural parts we call this Instagram manager uh we have examples here of wingsparent two locations uh next parts that I would like to explain to you the wording some of you or most of you already know this it's the wing Stringer so you have this here uh in a gray color a lot of uh small longitudinal longitudinal Parts the wing stringers and in Serbian we call this us or sometimes we also call this stringers and uh at the end we have Wing grip so here we have on this very photo we have Leading Edge rib uh Central rib and trailing Edge rips in this case Wing grip is split into three different parts so we call Win Win grips similar in something we call it terrible okay so but I'm guessing most of you already know this so in fuselage we have equivalent parts we have bulkhead which is the equivalent of wing grip or frame so bulkhead is a stronger frame frames are doing the same same purposes as doing grips we have Wing skin we have a wing Stringer same as sorry fusel Stringer which is same as Wing Stringer and we have longeron which is very very similar to wingspar so many inputs into aircraft performance so if we if we talk about complete performance I would like uh to get you to focus on on these two uh parameters which are very very important for complete flying of the aircraft so I'll I'll try to like very very simplify aircraft and out of all all very big complexity of uh of this very complex and beautiful machine playing I would like uh to focus in simplify this on only two different aspects and one is the aerodynamic shape and you can see here like how the aerodynamic shape can be in a simplified ways uh determined from uh initial sketch of the aircraft but what is important of the aerodynamic shape the outer shape of the aircraft uh is what uh defines how the aircraft will behave in the air so this is this is one of the main main factors because it gives aircraft the possibility to do all these beautiful movements in the air and take you from place a to place B but what is so so we can we can look at the outer shape is the is the driving positive factor and there's one big negative factor which is sort of uh working against the aerodynamic shape or the outer shape and this this is this is the weight so so these these two factors are very important Auto shaping the weight so Auto shape is giving you all these beautiful movements and the way it is uh is working against it so you want to have a good outer shape but there's low weight as low rate as possible so so how how do we how do we do all this together on or what is the task in hand well task is to fill this error shell the outer shape with the structure that will support this shape but keeping the weight is close to initial estimate or as small as possible so for example if we if we have created our sketch like this of some potential aircraft which will uh perform good on a market or Market needs for example four-seat aircraft with uh triple blade propeller uh we can for example design from this empty shell so you see here only the shell you don't see the internal part uh we we want to define the structural Elements which which would uh fulfill this shell and make it uh strong and rigid enough so this is for example the example how can we build all these uh structural elements uh to sustain the structure so it does not break in the air so so we are going to talk a little bit about this uh for how do we put all these structural elements inside and what what do we need to take into account and what what would this all these parts do okay so in some very very distant or not so distant future maybe maybe we can build this aircraft if we would have some very very uh perfect material maybe we can build it completely as a shell so it wouldn't have internal parts but today because of limitations of the materials and processes we need to build internal parts same as in human body human organism that will sustain and support uh all the uh outside loads and the aircraft most of the loads uh come from the air moving then from inertia weights uh then from propulsion Etc but we're going to to talk a little bit about the role of these parts and how do we make this uh perfect arrangement okay so how how to do this how to create this structure which would be as as light enough as possible to reduce the weights to the minimum so we have what is called the lightweight design and it has some universally accepted principles there in Aeronautics so so I'll explain what they are so one of the main things is that Parts should serve multiple purposes so if you have on one part which is serving two purposes then and you don't have to uh um multiply uh the different parts you would have less per account and uh therefore smaller weight so in in a typical aircraft design all the parts should carry loads so you you should try to avoid Parts which are on the aircraft which don't carry any load because they don't carry any load they know they're not serving the structural purpose so you should try to design Parts in such a way that they are carrying at least a part of the aircraft plug then use of the uh Advanced Materials with lower density this is obvious if you use some normal materials for example as a carbon fiber or some Advanced Metals then with lower density you can get a lower weight of your aircraft then load introduction in the in the uninterrupted and simplest way possible so it's not very easy easy for me to explain this in simple terms because uh knowledge of um structural mechanics and uh resistance of materials and strength of materials is required but basically if you're not introducing clothes in a more simple way you're generating some extra unwanted loads such as parasitic moments and this is loading your structure additionally and therefore you need to carry extra weight so this this is very important but you can only understand this with a little bit of practice and experience then additionally buckling design and the ultimate loads for metallics so buckling design basically what it is is you allow for aircraft skin uh to deform a little bit and for some structural parts you allow them to deform it at very very high loads and then later on they return uh to the normal undeformed state uh and then as much as possible uh add sandwich and core area this is for composite materials so Composite Materials they have sandwich area and course so sandwich and core uh they uh help with rigidity so sandwich and core you can you can think of it as for example bees uh honeycomb so honeycomb structure is a very very well and very much used in composite materials and then you have rules such as minimize the edge distances and Footprints so this is the distance from the center of the hole which is for example drilled in a part to connect it and to another part so if you try to minimize uh this Edge distance and the shape of the footprint of the part is as much as functionalize it then you you'll have a light Ray design and then you can use Advanced topology optimization for trust structures this this is like Advanced topics so I wouldn't cover it a lot you just need to know that it exists so I took four four main principles here uh from the University course from Professor Alexander pantovich so this is what he taught us when I was studying a long time ago foreign upper skin so you learned all this so now we jump to the material selection so we have material selection Manufacturing Technologies and structural requirements from the structural requirements you need to understand loads structural analysis which is static strength and durability which is fatigue and damage Stones we we cover this uh already so I move on so drivers uh I already told you about weight which is one of the main drivers and connect connected with proper structural uh sizing and design of structural elements we have corrosion so on on all metallic aircraft uh you have a risk of corrosion so all metallic parts are as susceptible to corrosion so uh there are ways to protect against corrosion but this this is one of the drivers for design of metallic aircraft then we have for example lightning strike protection so whenever every every single aircraft in average you have every two years lightning strike so this this isn't normal but there are ways to uh protect against damage of lightning strike drivers driver is also a cost then durability or fatigue we already mentioned this and then we have maintenance repair these are some of the main drivers for for the design of uh structure of an aircraft so material selection uh I'm guessing most of you have heard of all these different materials and maybe you know the usage and the roles of all these different materials in uh in the design in my picture of the aircraft but I'll just mention uh briefly a couple of words about all of them so you you get an awareness why we use some materials and why are they good and where they're bad in some application thank you so requirements in material selection are density for the weight obviously corrosion resistance we mentioned cost static strength fatigue strength or durability crack propagation electrical conductivity and there are many many other important requirements but they are listed here in I would say order of preference so if we start with with boot so you don't hear a lot a lot about today about wood in aircraft design but in the past this was one of the main materials used for aircraft design and manufacture uh so what what are what are some of the benefits of wood well it has low cost low density it has a fair strength to weight ratio these are all good things so even today there are some aircraft uh which are built in wood so I would mention for example there is a French manufacturer Robin I don't know if they are still in a in existence or not but up to maybe I don't know some time ago or this this aircraft there used to be used in service so so this is one of the relatively modern aircraft still building wood but what what is wrong uh with with the with the wood well it has poor fatigue properties poor propagation so this is always very very bad so what is good there's no corrosion uh then no electrical conductivity so this can be both good and bad uh today is almost obsolete but it gives slightly on uavs or drones uh what's interesting to know is the design and Analysis are very very similar to composite materials so if there are any of you who are involved in one or other way in the design or manufacturer or maintenance or whatever it runs in uavs just that you know that wood can be used in uavs and can have some benefits and a relatively low low cost and low weight uh then we switch um to aluminum and this is example of a civil aircraft fuselage sorry Andrea to to interrupt you but you said for electric conductivity that is and good and the bad okay and you let's explain in short short words yes what do you mean by that so good good thing is for example if you have lightning strike it wouldn't strike on uh on uh outer parts of the architecture made from wood but what is bad if you have some equipment inside then you cannot [Music] um you cannot distribute uh uh the effects of electrical lightning strike you cannot distribute this this discharge well and it would be difficult to protect uh the electrical equipment so you would need to make some fake electrical network from metallic Parts this is similar what is what is done on composite composite aircraft now because they don't have inherent electrical conductivity uh you have to create a fake electrical mesh in a wing and fuselage just for propagation of the effects of lightning lightning strike okay okay thank you no problem so we have uh we had to split this presentation into two parts because um we had some problems with the zoom account so this meeting is going to end up in uh about two minutes and then we'll jump to the second invite so just so you need to know that you need to log on on the second uh second link that you got from us so uh we have here example of similar to fuselage which can be aluminum and usually typically is aluminum except the latest generation of uh civil aircraft which are made a lot of composite materials but for example a lot of aircraft that you fly daily with or where you when you go on holiday for example A320 or uh Boeing 737 they all have a uh metallic fuselage so so this is still still very very uh applicable so you have here uh uh a sketch which is which is showing you how some different parts of the aircraft are sized and what is the sizing uh uh criteria what what is the drive so all the green is double internal pressure so you have internal oppression in the aircraft which is coming from the air and then you have some artificial over pressure which is applied to keep the passengers feel comfortable because if outside pressure would come into cabin it would be too low and too uncomfortable for the passengers so artificially you apply over pressure so you have this pressure difference and depending on which altitude you are this pressure differences uh loading the fuselage so everything in Black which you see on the underside of the fuselages are so-called loads from landing gears or Landing uh then you have uh colors for lateral Maneuvers elevator maneuvers gust which is sort of like the air movement violent air movement then you have side gusts it's also a violent air movement and you you have some miscellaneous factors which can be a range of many different factors okay so we are going to end now and I'll just uh restart uh the new uh New Link in couple minutes please uh be patient with us we continue with the explanation of uh aeronautical materials and material selection so to add what we said about aluminum we have here some comparison of the good and bad points or good bad sides of of aluminum as an aeronautical material so good sides are fairly low cost which is obvious that doesn't need a lot of explanation low density you all know this that aluminum is one of the most widely used materials in navigation so it comes the effect uh that it's very light comes from low density it has good strength to weight ratio it has good fatigue properties and good crack propagations so these two things they're connected in a way so fatigue properties it means that aluminum is resistant to repeated loads or cyclic loads which change its magnitude in time and crop crack propagation is connected to the effect foreign selection and we're going to talk a little bit about aluminum as aeronautical material so is is probably most of you know or or all of you know aluminum is today the most widely used aeronautical material for many of its benefits but it does have some uh bad sides as well so it's fairly low cost this is obvious doesn't need a lot of explanation low density this is connected to to the property of the chemical um characteristics of the material it has good strength to weight ratio and now two very interesting properties it has good fatigue properties and good crack propagation so fatigue properties they talk about uh thing that this material is very resistant to repeated loads so if you have some loads which change in magnet magnitude during time then this material would be your good choice there are different kinds of Alloys of aluminum some are even better in this respect some are like average or medium quality in this respect but generally aluminum is good for material if you want a fatigue strength crack propagation is connected in a way to fatigue so what crack propagation is uh is following sometimes we allow on aircraft either their civil or military or general aviation we allow on some specific parts for cracks to develop and these cracks we even allow them to grow on the aircraft up to some specific limit and then after this limit is reached this part is replaced in service Replacements of the parts in service uh due to fatigue properties is done in following two ways it's either done on a Time basis so there is a time limits for some specific part in this time limit is usually uh defined either by analysis or by testing or combination uh or the timing interval for um replacement of the part can be determined by uh in service uh detection and measurement of the speed of the crack propagation and this this is typically done by using NDT methods which is the acronym for non-destructive testing so non-destructive testing can be uh methods to test the material without uh physically destroying it so you do this by some means like you would for example expect inspect human bodies so everyone is um I'm guessing uh familiar with for example x-ray so the way x-ray is used to examine the inside of the human body there's a similar way to try to determine what's happening inside of the structural parts on the aircraft for example or you can use for example [Music] um ultrasound or some other different methods which can tell you if there is a crack developed inside the part and how big it is and how fast it's growing so you measure this over time Etc so this is this is why this crap crap propagation properties are very important then Fair corrosion resistance we have in aluminum so normally in general life you think aluminum is completely non-corrosive material but actually it does it does corrode but it it has a relatively good corrosion resistance although not perfect uh but there are there are ways uh to um to protect aluminum in service uh to uh make it even more corrosion resistant and this is done by um uh protection such as uh aluminum anodizing oxidation and later on painting aluminum is typically painted in at least one one or two layers of paint um then uh aluminum has good electrical conductivity and um why is this important uh because of the lightning strike protection for example so um typically every civil aircraft sees in every two years at least one lightning strike in average statistically speaking so when there's a lightning strike on the aircraft skin um it's important that this energy of the lightning strike is evenly distributed a long aircraft structure so there's no concentrated damage in one small local area or local point uh and this this is why aluminum is is good like to spread this complete energy and dissipated around the aircraft structure and some of the materials does not have this but aluminum does it it does um then some of the beds sides of aluminum especially in today's modern context um aluminum is uh corrosion incompatible with cfrp which is acronym for carbon fiber reinforced Plastics uh and uh in contact with the cfrp cfrp is making aluminum corrode uh aluminum is also a corrosion incompatible with titanium and steel so this is why we need to to coat aluminum in paint and protect it in this way when it's in contact with these materials and again what's what's good for aluminum is there is a good corrosion sorry there is a very big variety of processes available to make the parts today of you know aluminum like Machining sheet metal forming many many different uh processes uh on the trivia I wanted to ask you what the aircraft is in photo and we have here UTV last 95. which is uh almost like very high percentage of aluminum and this is an example of a general aviation trainer or piston trainer okay so we go forward uh to still so it's wrongly written this this is my typo um which should have stated still instead of aluminum so still is one of the oldest used aeronautical material or metals it's not most widely used in aviation but in general in engineering it's most widely used material so what are the benefits of Steel it has very very low cost even even compared to aluminum it has a high density which means High weight he has very strength to weight ratio uh extremely high static strength so this is for for the loads which don't change in time it has good fatigue and good crack propagation properties which we just explained uh um in on a previous slide corrosion resistance varies from good to bad so for example if you imagine every one of you uses Cutlery uh forks spoons and knives every day in your life to eat so you know like when you take uh your Cutlery and put it in a dishwashing machine you know that after after it's been washed the cutlery would not corrode so this is example that some yellow is some steel Alloys are completely corrosion resistant but there are some Alloys which which are not corrosion resistant and which do corrode in service still has a very good electrical conductivity and I explained on previous slide why why this is important and why it can help what's interesting about still is that there is corrosion incompatibility with aluminum which we already mentioned so in contact with aluminum uh there would be a bigger damage to aluminum than to still so aluminum would corrode faster there's a big variety of processes available and still is good the elevated temperatures so still can be used for example in jet engines or anywhere in the vicinity of jet engines so this these are some of the good properties of steel and the trivia is which aircraft Landing here we see on this photo and this is this is the landing gear of so good foreign company [Music] located in the territory of Bosnia here to go in and at the time it was in former Yugoslavia uh and Ultra and aviane are located in Serbia and Romania so this aircraft was made in cooperation between former Yugoslavia and Romania uh and it's still used in Air Force Serbian Air Force and Romanian Air Force here he has withdrawn this aircraft type and generally in appearance is a similar uh to uh jugular aircraft um so now we jump to Titanium so titanium is uh my personal uh best preferred aeronautical material and for sure it's the for in general it's the best of of metals used in aeronautics so it has some of the very very interesting and uh good properties and also it has some some bed size which we're going to briefly uh explain so it has a low density so it's even even lower density to aluminum and lower weight it has excellent strength to weight ratio so the best of metals it has very high static strength good fatigue and good crack propagation properties corrosion resistance is good corrosion resistance when I say it's good it's it's even it's even better than aluminum and we're going to talk a little bit about what that actually means a little bit later on it has Fair electrical conductivity uh what's interesting it has a good corrosion compatibility with carbon fiber which is why it's used on uh almost modern aircraft in use today because carbon fiber is is material of today in future and it's uh gaining in market so so-called market share so it's or percentage of uh news on the aircraft so it's used more and more on the aircraft because of great properties we have a low thermal expansion in titanium which is com which is comparable and compatible with carbon fiber it has good vulnerability it has a lower resistance when uncoated so if you need very resistance then you need to to take these two into account so where is usually um uh present when you have some parts in contact which are which have a relative movement between each other um what's one of the biggest uh dead sides of aluminum is that it has very very high cost and um processing making making composite parties not that easy it's not as easy as as uh still an aluminum just to get to the to the titanium part uh it has a good elevated temperature properties and this is why it's used generally on jet engines a lot and we have here the example of the aircraft on the photo it says aircraft Landing here but it we actually meant aircraft here and this is the photo of Lockheed s371 black bird which is made uh in very very high percentage in titanium almost all structure is made out of titanium uh this is this material Choice was made because uh uh because this aircraft is flying at very very high speeds and at these very high speeds uh the heating becomes important factor factors of this aircraft is hitting a lot and this is um why it was used but also for uh for lowering the weight so it's combination of a couple of uh uh good uh properties of this metal is why it was used on this like very very um high-speed aircraft okay so we have here an example of an aircraft landing gear um this is landing gear of modern civil aircraft and we had a trivia question here what is the common way to protect the surface of the titanium parts from corrosion aircraft so the options would be uh primer paint plus top coat paint uh primer only top coat paid paint only no protection and passivation on so correct answer for this question is passivation on so passivation is the means to three uh three to the titanium chemical process in which you don't change it physically appearance and you don't apply any material on top of it but you just uh changing uh the electrical charge of the surface part of the metal in such a way that it it doesn't react it becomes uh less reactive in contact with other materials but why is this important is because like it's cheaper process and you don't even own aircraft when you see landing gear sorry when you see a titanium Parts such as on this Landing you you can see this that it has this uh bright metal look and finish without any visible layers of other materials outside such as coat of paint so it just shows that the the titanium has the this great anti-corrosion capability and it's very very stable against corrosion and for example landing gear that you see on a photo has uh very tough in service life in which you have lot of water rain mud humidity and even even it is very very tough locations you can use um Titanium without any external paint and if you ever wondered what aircraft Landing you we see on this photo this is this is the landing gear of Airbus a350 so other materials in aviation which are used maybe less frequently but still used a lot so we have cap relies they're um very much used on the aircraft but maybe not in that bigger percentage but they used for some important parts such as bushes and sacrificial parts and we use copper Alloys in this application because corporealis are softer than steel and can be easily replaced in service so everywhere where you have a couple of Parts relatively moving to each other and you have where then you choose copper as a sacrificial part which would vary in service and then after some uh time limit or inspection you can replace the copper parts or copper alloy parts then we have nickel Alloys so we have internal in Canal is used for for Fasteners because it has higher strength even even than uh titanium Fasteners and it's used a lot in jet engine because again it has high strength and it's also resistant to high temperatures uh then we also used from Nicole Ellis for example alloy called monal so monol is used a lot for Fasteners even even in general aviation aircraft it's very very widely used um then we have magnesium Alloys which are a little bit less widely used uh they you used uh a little bit more in jet engines so main reason is is lightweight so um they have uh 66 percent of density of aluminum and only 25 density of the steel uh there is wide range of fellows available they again similar as some other Alloys have good temperature compatibility uh General corrosion performance is uh competitive compatible incomparable to aluminum alloys ease of processing by casting Extrusion forging and machining is available it has good availability by Mig and tick processes and it has high dumping capacity if you need this specific performance summer then there are Composites but they require uh separate separate presentation because there's they're very different to metals and it takes a little bit longer time to explain what the Composites are and what are there main characteristics and we have forms which are used in in Composite Materials but sometimes they're used also not connected to Composites and they're used a lot on uavs and drones such for example as polystyrene okay so we come now to the Manufacturing Technologies ah now we're going to talk a little bit about Manufacturing Technologies which affect structural design quite a big way so available Manufacturing Technologies affect structural choices in a following way so more Machining and CNC Machining intensive manufacturing resources drive integral build so what does that mean so so if if you look at the the picture uh on the bottom and you take a look at uh examples f and g which are integrally machined web and integrity machine truss so these are for example the shapes of the aircraft part in this case it's a Wings bar and these parts are uh best uh made using Machining in CSC Machining so if you use some other processes you wouldn't be able to get parts which are formed like this which has the exterior shape like this so what's good about for example integrally machine Webb and integral machine truss is that they can be for example made as one single part from one single block of metal and these These are typically examples of of the shapes of Parts uh which are built in metal in some other materials you would build them in a different way although although integral machine web and integral machine trust can also be done in wood if you want to choose wood today for example I don't know for some drone UAV or something like in this some unmanned application would can be Fair choice so what's good about integral Parts is I told you they're one single part and you don't have uh the weight of connecting elements so if you if you look at the example a which is built up web built up web it's not actually Single part it's in an assembly so disassembly uh it has a couple of different parts which are connected together by Fasteners such as for example River rivets or bolts or screws so if we have a built up web you're getting also the weight of the connecting connecting Fasteners which you don't have in Integrity machine parts so you can see how how your choice of manufacturing technology is affecting affecting weight but maybe also the cost so it's maybe a little bit arguable today what is the cheaper technology but in past you would make part A built up web using um sheet metal formed sheet metal forming which we're going to cover later on a little bit more and if you would make a lot of aircraft for example say in second world war and where you're building I don't know tens of thousands then um built up web maybe the the cheaper option uh but today when the quantities of aircraft builds are not in thousands but maybe in hundreds uh then integral Machining or CNC Machining um maybe uh even the cheaper Choice it may be a lighter it all depends on on quantity so if you have very very high quantity such as for example in automotive industry then you go you go a lot of sheet metal forming which is typically done on on a bending press so this is this is how uh less CNC capability drives differential build so if we look at the bent up Channel which is option C bent up Channel can be made both in sheet metal but it can be made also in composite materials so in Composite Materials typically if you want to build a c-shaped part such as on a c option here on on this photo you can for example um make for example unbent planner shape of of of this [Music] um Spar and then you can put it in a tool and form it in this tool to go from planner to the C shape this is how how the spars are built on some of the modern aircraft which have a lot of composite materials but in order to do that the best way with lowest weight and best performance is to use a highly automated fibrant tape placing Technologies if you don't have um the luxury to have these highly automated process you can still make composite Parts but you can make it uh using uh more manual processes and this is for example by using vet layout and using wet layup you get the parts which don't have the best possible properties uh and you can um you can do it for example by using uh um processes such as such as for example or resin infusion or resin transfer molding these are all also with these processes you can also make high quality parts so out of these processes for Composites that layup is is the gives you the parts with the lowest quality and lowest performance so today in today's use we mostly see the sparse which are built like f so you would have this for example on all Airbus aircraft so on some of the Boeing aircraft you would see Parts which are either combination of f of f option or maybe a option so still on on a lot of Boeing aircrafts some parts and assemblies are made this built up web historically and if you're making uh uh sparring composite material then you would you would use a shape which looks like C which is bent up Channel although as I said previously bent up channel can be also made in sheet metal as well so metal Machining today is 99 CNC so what is CNC cnc's an acronym for computer numerical control so basically this is just a nice word for uh computer controlled Machine Tool so here we have a couple of examples of um of some parts which are made by CNC Machining so we have here uh Ming spars which are made in aluminum so these These are examples of integral spars that you've seen on the previous slide we have here a lower fuselage frame of uh of a general aviation aircraft for example um then we can see here Wing grip for uh typical civil aircraft for example uh on Airbus aircraft doing grids look like this so they're like mostly single piece some sometimes assembly is where you would revert or Bolt the rib feet which are some smaller parts of the wing grip but sometimes you you would have it as a single part which is machined typically out of aluminum from single block of metal and in a lower right corner you can see a photo which is uh showing the description of how CNC metal cutting looks like so you you have a high resolution per minute or very fast spindle in which you put your machine tool Cutters so for example like a Milling tool and then this Milling tool is slowly or sometimes very quickly uh grinding away or chipping away small pieces of material until this complete part is formed and this is a very very widely used process today still regarding metal forming uh the the typo here which is uh mentioning um CNC Machining in in the first sentence but we're going to talk on this slide a little bit more about Metal forming so here we have a couple of Assemblies of uh metal formed parts and we have in a bottom uh uh picture of the actual process of uh making uh metal form apart on the Press so so if you look at a part in a top left corner this represents trailing Edge uh rib uh assembly which is a sheet metal formed so typically so I'll explain the process later on let's just look at the parts first then the top right corner you have front fuselage built uh from sheet metal parts so this is like complete big assembly of a complete fuselage which has a lot of sheet metal parts and how these parts are made well you have uh typically bending or sometimes stretching press and uh you take a sheet of metal which can be relatively thin it goes I don't know down to 0.4 0.60.8 millimeters sometimes these are like thinner thinner uh thicknesses of the materials but it can go uh too hard thickness such as one millimeter maybe two millimeters and then you put uh sheet sheet sheet of metal against some tool and then presses uh pushing this metal against the tool which is like uh like a mold for example in a kitchen like when you want to make I don't know some cookies and you have some shape in which you want to shape your your cookie or biscuit and this is a similar way but it's in the opposite way in which you are forming the metal or on the top on the outside of the mold not on the inside typically on the outside so you can later on remove the part from the mold and so these processes they can be done uh with help of the operator or sometimes they can be done more automatically but typically all operators is required to prepare the sheet metal connected to the mold and then to to put it manually in the press and then on a push of the button uh press is applying very very high force and of forming the parts so if you have uh if you have a High quantities uh you can get relatively cheap parts why is that because the the process is relatively fast so you can form one simple part in matter of I don't know seconds or minutes while if you have machine part then it takes you more which is like minutes or tens of minutes and sometimes the hours and this is why metal forming is cheaper than Machining because it's faster but in order to design proper metaphor metal form Parts it cannot have all the features it has some limitations on Geometry while CNC machine parts they have less limitation of how the actual part can be formed the end and shape of the part uh now we're going to talk a little bit about Composites so Composites they're like material of materials of today and in future they're most widely used material aircraft built today so most of the seal aircraft have more than 50 percent of composite material percentage so in the top left corner we see the incomposite part 4.787 this is the example of where the composite materials

are used such as for example carbon which is most most widely used composite material in the aviation today in the top right corner we see which is a Student Competition team from University of Belgrade uh also a full UAV or full drone unmanned aircraft which is made out of composite materials which is very very common to make unmanned aircraft today out of composite materials and in bottom picture we see reinforcing skin can be in this case I've written Ming skin but it actually may be a bulkhead uh like a complete frame for for the fuselage but it can also be a reinforcing skin it doesn't really matter these are the typical Parts which have one planar element which is like a plate and then you have reinforcements which are in a form of some specific cross section for example letter L like L-shaped section or TC t-shaped section or maybe Omega shape section Etc so now we jump to the structural requirements so I'll list them all and then talk about each of them a little bit so first and most important structural requirement is the strength when we say strength V mean and think and speak mostly about static strength strength so static strength is strong enough so basically what it means is that the structural element does not break under application of Maximum loads that the structure is going to sing in in a few in um in the use uh stiffness stiffness this is uh to do with the deformational structure so in some specific cases uh we need to make sure the structure does not Bend outside or does not deform outside of uh some specific limits why would this matter well for example if you can imagine maybe movable surfaces such as slots flaps ailerons so for example because they're moving in a case that they move and also deform there could be a contact of between two different structural elements in in the case of contact they could be aware or maybe a damaged Clash or maybe the some of these movable elements wouldn't perform their function or maybe in case of landing gear if there's a deflection during retraction and extension it may contact with the landing gear base so we need to make sure that all the structures are stiff enough that there's no contact or or damage [Music] durability uh is is to do with the fatigue so it's it's to do with the applying repeated loads on some specific structures so in time if uh if the loads are variable in time if they change their uh intensity uh maybe even the direction of application then they would be under fatigue conditions for mostly for metal for for composite materials is a little bit different but metals they are prone to material fatigue so we need to make sure that during complete life cycle of of an aircraft uh structure would be able to sustain uh these uh loads which varying time and if if the structure cannot sustain these loads then we need to make sure that we know exactly when the cracks will develop and then if we allowed for specific structure for cracks to develop we need to make sure and we need to know how fast they will grow so we replace these parts in a timely manner then we have particular risks so this is the term which covers events such as Starburst disc burst bird strike uh it's written Ben blade off but it should be fan blade off uncontained engine rot of rotor failure Etc so Tire burst this is the case in service which is not not the trailer when the tire burst due to where due to some damage or combination so we need to make sure that entire birth event uh uh doesn't um affect the aircraft in a catastrophic way so you will see that most of the tires on on the aircraft are usually doubled so on one wheel on one leg you usually have two wheels and two tires so if one tire bursts then uh the other Tire can uh perform this function but it's not just that we need to make sure that these fragments if there are bursts that these fragments when they uh when the tar explodes these fragments uh cannot create uh big enough damage so see memories for disc burst but this disk is the term which is uh applied to the parts of jet engine rotor so different stages of jet engine rotor they are called disks so if some of the disks burst and a fragments of jet engine rotor um explodes in a way or it detaches it needs to be contained within the shielding of a jet engine so it needs to eject the jet engine only on the back a broad strike is connected to to obviously he hit to the aircraft on board so you know that famous case of uh captain sullenberger on River Hudson went to jet engines shot down in service uh so this is for example the case of of the bird strike what's important in bird strike is again that it's contained so all the parts um of the jet damage jet engines uh should exit uh through through the jet engine nozzle they shouldn't they shouldn't uh deflect and cause some other damage outside of the jet engine uh but the the bird strike uh there are also um cases which are checked for bird strike if the bird is hitting not just the jet engine but but parts of the structure for example such as a Leading Edge of the Wings so there is protection that with bird strike is hitting in in case that brought these parts of the birds are hitting um uh some specific parts of the wing they told the systems inside are protected and the damages such that the aircraft can continue its flight fan blade off uh this this is famous case fan is uh so-called uh or you can imagine it as a first stage of jet engine if you look at the jet engine from the front this is this is all this big big blades that you see the former blade this is like the biggest rotating element or biggest rotating assembly on a jet engine so in a case that fan blade is off uh there is some certain amount of a symmetrical load uh and uh jet engine should should shut down in a controlled way again and it shouldn't uh pass the possible vibration and imbalance to uh other parts of the structure and this is also similar as a broad strike for jet engines this is this is uh uh tested on live tests in service so this is a very very spectacular test if you if you Google this you'll find uh videos of how the fan blade is detached in tests and what what happens next and contained engine rotor failure so this is this is the case in which uh bigger parts of uh jet engine uh births and explode and move from the jet engine this is very very very unlikely event but in case that it happens uh the trajectory of the uh uncontained engine rotor failures should be such that it doesn't uh protrude through some important systems um for example on of Ingleside hydraulic systems or electrical harnesses Etc okay so regarding strength when we talk about structural requirements I will list all the points here and talk about each of them so uh potential failure modes or uh loads of the structure so on a big seal aircraft you have a lot of different load cases for each part of the structure for each sub-assembly so you need to make sure that for all these different uh load cases uh there isn't a failure and in the case there is a failure uh it needs to be ensured that there is a duplicating element which is uh fulfilling this function and that some other part or parts of the structure uh can can take the function of the failure element so the uh this slide here is a little bit older terminology instead Jr far regulations so gr is the all old name for uh European regulations today they are called CS CS requirements and for our American requirements and they're mostly cover the design of build of civil aircraft today in the world most of them are certified by by these rules so uh Cs and father regulations for Rich aircraft category for example like big civil aircraft or helicopters or maybe general aviation aircraft it's uh it's a set of regulations relatively detailed and there are also additional documents which are in interpretation of uh what each of these requirements are and what should be the means of compliance how you show that all these requirements are satisfied but basically these are the rules that must be satisfied in order for one specific aircraft to be certified and it receives uh type so-called type certification load cases I explained briefly many different log cases for uh different parts of the structure they come from inertia forces uh which is mostly from the weight of each individual part but then applied by some uh coefficient of load depending on the attitude and position of the aircraft in some specific uh [Music] position during flying then they can come from aerodynamic law they can come from ground loads during Landing so all these combinations they're normally identified and analyzed in very very rigorous way structural redundancy multiple load parts so I explained this little bit when I was talking about potential failure modes so um depending on the categorization of the structure some type of structures they need under some specific categorization they need to show that they have multiple load paths so in case one part of the structure fails some other parts of the structure need to take this function but this is normally used for for a very very responsible elements so-called primary structures without which the aircraft cannot fly or cannot safely land but there's some structures say for example like wink deep and maybe some callings which can sustain full damage in flight and aircraft can continue to fly normally safely but the percentage of the of the structures which are non-primary on aircraft is relatively small and then we have cases of non-linear Behavior such as plastic grade distribution of stresses and post-buckling behavior um so plastic redistribution of stresses this is mostly applicable to um um metallic materials and again post-buckling behavior is also connected to both to metallic materials so plastic redistribution of stresses what it is for some specific part which is made out of metal uh when the loads in some case um exceed their uh load carrying capability of that specific part then metals can slightly deform permanently in the location of of this overload and this permanent deformation helps alleviate or lower the stresses so sometimes we analyze this and in some cases we accept that we would allow in some specific cases for some local uh permanent deformation of structure uh post-buckling Behavior this is uh buckling is the case of easily most easily explain this by um uh skin buckling or skin deformation skin [Music] waving I don't know how to call it but basically uh mostly for the upper surface of of the wing or maybe upper surface of the fuselage in some very very high loads uh there is deformation of of skin which looks like a wave or maybe you can look at it as you know or orange peel or orange skin this is normally only only temporary temporary occasion and when the load is back to normal the skin goes back to a normal shape this is called buckling but uh sometimes we also analyze what's happening uh uh when this when when uh the buckling gear is finished in a way when the skin is unloaded so we we want to make sure that uh there is no permanent deformation or if if there is permanent permanent deformation we need to make sure that we understand very well what it is and it that it doesn't cause any uh any failure of the structure at the end foreign so regarding regarding structural requirements in strength we have couple of other points to briefly mentioned so we have our elastic effects such as flutter so I will show you a couple of uh of videos so you understand better we have the effects of ferrodynamic drag so aerodynamic drags same as zero Dynamic lift uh is is just another Force which is acting in a different uh different direction and this is mostly in a direction uh opposite to direction of light so this is also loading the structure so we have a flexible aircraft loads so flexible loads we have typically on moving surfaces such as uh sleds flaps ailerons so we need to take that into account then we have interaction effects slats and flaps so when both slats and flaps are for example applied then the aerodynamic clothes are different so so there's a coupling of aerodynamic forces so this also needs to be taken into account uh build tolerances so what this is uh every every single part which is made made on the aircraft is here it has some specification which is normally technical drawing some technical drawing you have uh limits for all the different dimensions of the parts say for example if you imagine uh length and width of the part it has some specific dimensions but also tolerances so each and every part is not made ideal but it has some limits which can be sometimes very very precise and in some cases they don't have to be precise but in any case when you connect a lot of parts which have some slight variation in dimensions then at the end the assembly can have also also uh variations so these build tolerances they affect uh structures in such a way that they may introduce some small additional uh loading onto the parts so this needs to be taken into account in analysis as well and then transportation and handling issues there are many uh different Transportation requirements but let me just talk about um the fact for example now that uh the aircraft even big civil records they need they have to be in some specific cases lifted from the ground maybe let's for argument's sake to replace Landing here and so if you want to leave leave the aircraft you need to have some uh points uh for jacking of the aircraft where you put Jacks and these points they're called jacking points so the these points they have to be designed in such a way that you're not introducing some permanent uh deformation and load into the structure so so you you need to make sure that you don't damage the wing or refusal as just by checking it but there's specific conditions the aircraft would obviously have to be uh attemptive weight but just so you have this in mind that what these requirements are so when we talk about flutter so you have here a example of aircraft being fluttered so what it is uh these these are some oscillations uh which are combination of the rigidity of their combination of two different factors one is the rigidity of the Archer structure and second one is the aerodynamic loads and also in a way uh inertia is affecting this so under some specific uh flight conditions the excitation of the structure can be as such that Wing in this case can start to uh oscillate and it can oscillate to such a higher levels that this oscillation is perpetuated in in such a way that the in end it breaks so during the history it's very widely known that some of the aircraft during flight testing later on in use um they they failed due to the flutter and a lot of lives have been lost but mostly of the test pilots so there's a very very rigorous way uh to First analytically assess possibility to being flatter and then later on to test it during flight testing to make sure that when aircraft enters the service it would not experience flutter and uh this similar thing to flutter uh it's called um tail bafting so everything here aircraft Wing flattery will twin tail bafting but it's very very similar it's uh it's oscillation of the structure which is excited from external aerodynamic clothes but uh what is affecting this are also rigidity of the structure and inertia properties so so if you want maybe to try to solve this you can try to make the structure more rigid and maybe put some concentrated masses in some specific points so maybe put some extra weight and try to redistribute how this structure is uh is oscillating um now we're going to talk a little bit about durability part of structural requirements I'm going to list all the points and talk about all of them in some level of detail so first we have fatigue which we explained is is the property of metallic materials and metallic parts that they lose their load carrying capability uh in in time or during time due to uh repeated loads which are which have their magnitude changeable with time or different in time which is changing uh its intensity and sometimes also Direction so damage tolerances is [Music] um a means to uh to fight the effects of fatigue in in such a way that we allow some specific parts to develop cracks and then we also allow these cracks to grow in control

2023-02-18 07:55