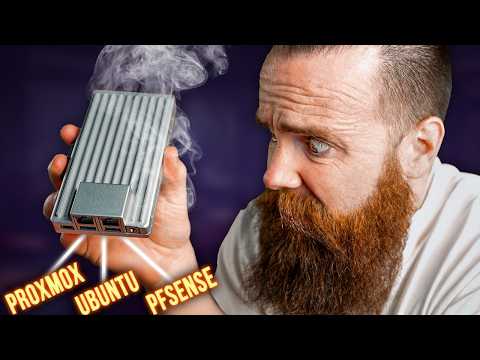

Webinar 2: Concrete Overlay Technology, Jan 2022

♫ music ♫ [Federal Highway Administration logo] Shree Rao: "We will review all the questions from participants and that will be answered during the Q&A session towards the end of the webinar. So I will do the presentations first and then get to the Q&A parts, but you can ask the question at any point during the webinar. To see a list of the participants, you can click on the participants button again in the bottom panel and if you want to raise a hand or if you have any reactions, there is a button on the bottom panel as well for those reactions.

If you have any technical issues with Zoom again please use the chat function and send a direct message to the two hosts. The two hosts are Monica Doebel and Eric Schulman. So if you send a message to Monica, she'll try to resolve the any technical issues that you might. Just a brief overview of today's webinar, I will introduce the speakers as I mentioned. Sam Tyson with Federal Highway Administration will give you a briefing. We'll provide a brief introduction

and give you some background regarding Everyday Count Six Targeted Overlay Pavement Solutions program and followed by that we'll have two speakers from CP. I couldn't have asked for two better speakers for this program most of you know them very well. Peter Taylor from the National Concrete Pavement Technology Center and Gary Fick from Transtec, and I will introduce them later on in the program and we'll follow that by the Q&A. So I'm gonna introduce Sam Tyson. Most

of you don't need any introduction to Sam Tyson but Sam is the Concrete Pavement Engineer with the Federal Highway Administration with the Office of Reconstruction Construction and Pavements out of Washington D.C. He actually runs the Federal Highways program to advance best practices for construction rapid repair and rehabilitation of concrete pavements and is leading Federal Highways' effort to increase the use of concrete overlays to extend performance of both existing asphalt and existing concrete pavements. So Sam is a registered professional engineer in D.C., District of Columbia and a graduate of the University of Virginia. Sam, please take it away." Sam Taylor: "Okay thanks a lot, Shree. As you can see on this slide

Tim Aschenbrenner from FHWA headquarters and Derek Nener-Plante from FHWA Resource Center are on the asphalt team. On the concrete side of course as Shree mentioned, I am at the headquarters along with help from Bob Conway and the FHWA Resource Center, so that's extremely helpful to me. I was probably surprised a bit myself and some of you may be that over 25 percent of all state DOT infrastructure funds go to pavement overlays. Now this is both asphalt and concrete given the fact that state DOTs manage 2.8 million miles of pavements, maybe this is not particularly surprising, but states do have to prioritize their funds and look at the most important use of each dollar that they receive. And this leads us into how is the TOPS management of pavements different from typical overlays and really they're not in terms of the technical process in which they're applied. They're different in the process of determining what the priority is

for the use of the overlays. High priority pavements pavements that simply cannot be taken out of service for an extended period of time, so the difference is really in the process of selecting which pavements get the overlays first. Our mission with the TOPS program of course is to extend pavement life, to take existing pavements-- both asphalt and concrete in the case of concrete overlays-- and overlay them to preserve the existing investment in the pavement that is in place with as little maintenance as possible on that pavement, which gives the DOTs the ability to both save money and to deliver the targeted pavement in the most economical and the most environmentally sound manner.

Our goals for the EDC-6 program really are to reinforce the use of concrete pavements for the DOTs that use them already, perhaps not to the extent that they might use them in total, and introduce other states to the use of concrete overlays if they're not using them currently because they can actually save a lot of money save a lot of time and preserve a lot of existing pavements for extended use through the use of concrete overlays. When we look at what's in the toolbox for concrete overlay products, it's really pretty straightforward for both asphalt and concrete, there's a bonded and an unbonded process of applying concrete overlay. Both Peter and Gary will get into some detail and how this is accomplished. I would just say that from the standpoint of concrete overlays, the unbonded overlay is probably the greatest percentage maybe 60 or 70 percent of concrete overlays are unbonded for performance issues but again I'll let Peter and Gary get into the details of those applications. Since the TOPS program includes asphalt as well, we should look at what's in the asphalt toolbox.

Tim Aschenbrenner is going to, in a future webinar, talk about this in detail but if you look down the list of asphalt overlay products there are what two, four, six, eight, listed that Tim will talk about in some detail. So we've got both concrete and asphalt overlays that are available for your use and we're looking to increase the use of those products through the TOPS program. The ultimate goal is to improve safety, improve performance, long-term performance, retain the investment in the existing asphalt and concrete pavements by overlaying, them saving money of course, and doing it all in an environmentally sound manner. So with that, I'll get back to Shree and Shree will introduce the next speakers."

Shree Rao: "Thank you very much, Sam, for the introduction to the TOPS program. So we'll start with the main part of today's agenda and our first speaker is Peter Taylor from the National Concrete Pavement Technology Center at Iowa State University. I couldn't have asked for two better speakers to talk about concrete overlays. Gary Fick and Peter Taylor literally wrote the book on concrete overlays and that's not just an expression, it it is actually true. So peter is the Director of the National Concrete Pavement Technology Center at Iowa State University. He's been involved in conducting projects and programs

in regarding concrete pavements and spends a lot of time helping agencies and contractors implement best practices in concrete pavement design, construction, and maintenance. He also conducts a lot of research that's focused on developing mixtures that are engineered to meet requirements of the environment that will be used in. He's a professional engineer registered in Illinois and is an active member of many professional societies. We're really glad to have you, Peter and present in today's webinar. Peter, take it away." Peter Taylor: "Great, thanks very much, Shree. I appreciate the opportunity to be able to

join you on the session and talk about a topic that we're pretty passionate about and it's also great to be teaming up with Gary is that I bring the theory and Gary brings "how do I actually do it in the real life." So I've got about 30 slides to go through so let's get started. What I'm going to be providing is basically a motivation. The value proposition of why we should be thinking about overlays. A lot of the material actually comes from a publication that Tom Cackler developed for us and has been published on the CP tech website. The topics I'm going to be covering include, you know, what's the issue, why do we bother talking about it, Sam has already alluded to some of the questions that we're trying to address, the value proposition, the barriers we need to get past, why people don't do it all the time everywhere, how to get started, and then Gary will pick up on some some successful projects that we've run in the past and some resources that are available to you as potential users. Okay so for those of you that work for agencies, departments of transportation, cities, counties, I've yet to hear anybody representing those organizations say to me that they've got more money than they can use.

Everybody is running on extremely tight budgets. They're trying to do more with less and working very hard to maintain and upgrade the pavement systems that they have under their jurisdiction. The bad news is that it's always deteriorating. Any time that you put something that lives outdoors, the weather is going to beat it up, the traffic is going to beat it up, and it will start to decay at different rates over a period of time. At the same time, the traffic's getting bigger, the traveling public is getting more fussy about ride quality and they're also getting far more fussy about continuous access to their roadways, particularly I live in Iowa predominantly a farming community and if you close down a road so that the farmer can't get his plant from his farm to the point of delivery, he's going to come out and get very ugly with you as you're trying to work on the system. And so continuous access is a pretty big demand. And so in many ways we're effectively burning the candles at the both ends. We're asking more

of far with far less resources in at our availability. So we have an existing pavement system it's a lot of it is actually getting pretty old and the Eisenhower system was built in the 60s and 70s, that's 40, 50, 60 years old and some of it's starting to get a little tired and it's not so surprising and that deserves to to tired it's survived very well and remarkably well over the period of time it's been exposed. So when you as an agency start to look at it and say okay we've got to do something about it, let's review some of the choices that you have. One a bit like we do in a lot of with our other activities, if you know my cell phone gets more than a couple years old I throw it away or at least recycle it so we can get the lithium out of the battery and go and get a new one. Now it's kind of tough to pick up 30 miles of pavement and take it into a store and say give me another one. And it's it's an effective approach to say we'll let's beat it up take it

out and remove it and replace it from the point of view that it's a long-term solution. You can buy another 40, 50 years with the product that you're putting down, but the negatives are not trivial. You have a disposal headache. There's a lot of material on every mile of existing pavement. You lose a lot of equity in the existing system that's not economically sound nor is it sustainably sound is that if you've got a good system in place that needs some minor treatment, it's an awful waste and an awful carbon load to simply throw it away.

It also takes time and energy and money to do this removal and replacement and at the same time the other one we're starting to pay more attention to is this whole idea of safety is that if you shut down a road for the several months that it takes to beat it out and replace it, traffic on the other roads, or if you're building under traffic safety becomes a real issue. And I've been encouraging my safety colleagues to start looking at this idea of a life cycle safety, as well as life cycle cost and life cycle environmental impacts. So all of those things in red may be considered negatives for this solution. So then we can also go to the other extreme and say well let's just patch it it's very limited in the amount of materials that you use in this photograph we've got the joints hav e started to fall apart but the rest of the slabs are actually in really good shape and so let's just do something with the joints. And this is not a bad solution

if you want a a reasonably short-term answer. Generally patches don't last, particularly partial depth patches, don't last as long as the original pavement. So they might buy you five years while you raise the money to do a repair. There's also the aesthetic. In this town the chief city engineer was pretty excited about the fact that his roads look so ugly in the condition that they were in having been patched the way they were. Limited usage, limited energy, limited traffic impact, but it's not a long-term solution. What else have we got?

And that's where we turn to this concept of using overlays. We do make use of the existing equity is that the system that's in place, we don't remove. We build on top of it. It makes a very good foundation for the new layer that we're going to be putting on top of it, and it means that we may be able to reduce the amount of material in this new layer because it is sitting on a pretty good system. It minimizes the sustainability impacts, again because we're reducing the amount of materials that we're having to put into place and replace, that a good that's a good benefit. Can be a long-term solution or if you're only looking for a few years

we can also tune it to be a short-term. So again it's very flexible you tell us how long you want to last we can design a system that will last for that length or maybe more. The biggest challenge with this is that in you know midwestern corn belt farm roads, you don't really care if you add another few inches onto the top of an existing system. But if you're

working in urban or city-based environments, the elevations, the connections to the side drains, the manholes getting under the multiple bridges that we drive under every day in our commute, those can be interesting and we do have to stop and think about that. There are solutions for all of these issues and we have published about those, but it's not just a slam dunk and we do have to think about it. So in this slide we've got more green than red that sounds pretty promising let's keep going.

Okay so let's look at this idea that Sam has already alluded to, a toolbox. And that's what we're trying to present to you particularly for those of you who haven't thought about this before. Concrete overlays may not be applicable everywhere but they should be something that you think about in a lot of cases. They extend life, they restore ride, they increase capacity and they can be applied onto a fairly wide range of existing systems. This photograph was a site that I went to that was undergoing an overlay treatment

and you can see the condition of it and not a lot of pre-treatment was being applied to this. So yeah we think it has benefits of being cost effective, sustainable, and providing what agencies need to keep their systems up and running. Alright, what do they cost, how do they perform, what are the environmental impacts. We'll touch on each of these in the next few slides. Basically there's b een a fairly significant growth in the amount of overlays being placed particularly since 2005 since we started talking about this. It was a bit of a dip in 2020 and I think that's more related to COVID and budgets than popularity of the system.

How much does it cost? People often ask us this and we gener ally try and avoid that question. It's politically incorrect, but here is some data that we did collect is that you're looking at about four to five dollars per square yard per inch thickness of concrete, but it's very dependent on where you are, what sort of industry, what sort of construction community that are familiar with the game in place, what are the costs and materials for you locally. But the message that we're trying to portray here is that it can be very competitive and it's well worth looking at this from a cost point of view. The other one is this is just an image that I stole from MIT is that one of the messages that's out there is that if you have an asphalt community and a concrete community that competition between the two different systems actually helps you as the user. We found that the single material communities tend to be paying more because there is less competition. Therefore if you're paying less because of better competition you're you're spending less dollars to maintain your network condition, and again there's a bunch of material available from MIT to support the this contention.

Environmental impacts, we think are pretty pretty strong. A long life meaning, you don't have to replace it every few years. If you can go in every 40 years instead of every 10 years, that's a quarter of the amount of material that you you're fooling with. It's also the amount a quarter of the amount of traffic delays, so you know those together have a fairly substantial impact on reducing environmental impact.

There is work out there indicating that a concrete pavement particularly under track traffic does cause the vehicles to burn less fuel and that's a benefit. That the high albedo particularly early on in the age of the pavement reduces the heat element effect and light reflect lighting that needs to be provided. The other sustainable part of it that we like to talk about is the concrete is fully recyclable, there are many sites around here where all of the if an old pavement has been recycled or replaced, all of that material doesn't move far. In fact there's machines that walk up and down our street our our roadways that dig out the old concrete, recycle it back into the base, and it doesn't move more than 20 or 30 feet. So recycling is a big part of our conversation. There's also some discussion about the idea that concrete will absorb CO2, so it actually may reduce its overall carbon footprint and that one is still under investigation by the research community.

Resiliency is the other fashionable term that's starting to get our attention as engineers. This concept that if we have a disaster how long does it take us to get back and functioning. And this is not a trivial question. Here in Iowa, we have a Missouri River on one border and the Mississippi River on the other border. And it wasn't long ago, both of those rivers were under significant

flood and a large amount of our farming community and many roads were inundated for several months. Whole towns had to be evacuated and stay evacuated because they were flooded by these two rivers. And in fact you know just watching the news right at the moment, disasters happening on the island of Tonga, sort of wonder if they're ever gonna be able to recover, because of both the volcano ash that's been dumped on him and the tidal wave that came and swept over them that place is in trouble and so it's not trivial for us to think a little bit about, okay a disaster happens how long is it going to take us to get back up and running? And the the conversation is being focused around the fact that concrete being stiffer imposes lower stresses onto the foundation system that means -- and is far less sensitive to the stiffness of the foundation system -- that means you can put rescue vehicles back onto the pavement a whole lot earlier without causing damage, and again that's not a trivial issue. We're actually working on a tech brief and hope to have that

published in the next month or two so sensitivity subgrade softening is markedly reduced. So is this the newfangled thing that we're talking about? Nope, we've been building overlays since 1901 there's about 2,000 miles of overlays in service in Iowa and again a large amount large number of them have been built in more recent years, but there's more than 100 years of experience on how to do this so let's look at some of these. How well do they perform? Well that's a bit like the economics question and I'll give you an economics answ er: it all depends. It depends on the thickness of the pavement of the overlay

that you put down it depends on the condition of the existing pavement that you're placing it on top. It also depends like anything else that we do in our engineering world, the devil is in the details. Are you getting the right details in place for the environment that you have, for the conditions and traffic that you have, and for the to to address the condition of the existing pavement. And Sam alluded a little earlier to this idea of bonded and unbonded.

The real difference between these two approaches and why we talk about them both is that unbonded if we put down an unbounded system it's typically placed on a pave an existing pavement that's in a fair amount of trouble. We separate the two layers because we don't want any cracking or other damage to reflect through the new layer so we allow the two different systems to move independently which means then that the upper layer has to be thicker to be able to be structurally competent to carry the loads. If we go with a bonded layer, then we're getting the structural benefit of that lower system because they move together. But

moving together means that the risk of reflective cracking is fairly high and it also means that we have to be pretty sure of that bond. Because the bond is less than we assumed at the design stage then we've got one layer that's thinner than it should be and the potential for failure goes up a little bit. And Sam alluded to the fact that most overlays that we're putting down at the moment are unbonded and that's partially because they're a little easi er to work with and they are known to be very reliable. The data and the plot that I have up on the screen there is from some data we collected here in Iowa. I think these were 12-foot panels, seven to eight-inch-thick sections, and you can see that if we draw a straight line graph through these things we're getting 30, 40 years out of them without any trouble at all. Now what we do find at the bottom of that plot, there is some systems which have not performed as well. We actually went back in and had a look at those pavements and it turned out that there

was always some sort of issue with inappropriate design, that the construction wasn't the quality that we wanted, or that the materials were not as specified so you know the premature failures are substandard but if we manage to build everything accordingly to the way that it should be done, we can really get a good long life out of these systems if we want them. Versatility, they can be applied on all sorts of surface types. We can accommodate all sorts of distress and again that becomes part of the thought process is the first question is am I building on top of asphalt or am I building on top of concrete? Well that's easy to answer. You go outside and kick it. Then you do the question of is

my existing pavement in good shape or is it in trouble? If it's in trouble, we will probably consider an unbounded layer. If it's in pretty good shape and what we're trying to do is to increase capacity or do a widening or to deal with joint issues then we can consider a bonded layer and so again we can cope with all sorts of trouble it just takes a little bit of thinking to make the wise decisions. They've been used roads, intersections, parking lots, airfields. It's not just limited to farm fields. Yes we can do use these systems almost anywhere. Can be really relatively quick. If you're putting down a six-inch section or even thinner, you move pretty fast, you can put a fairly big machine on top of it the 35, 40 foot paving machine you can be in and out of a neighborhood relatively quickly. You're also not really affected by the weather and we're starting to figure out how we can get traffic back onto this pavement within a weekend, particularly for residential traffic. I live in a cul-de-sac all of my neighbors are grumpy old

professors and when the city started talking about refurbishing the street, that was the message that the city engineer got. We want to be able to go home tonight and we managed to compromise it that yeah we'll get home in a couple days. And so I was pushing hard for concrete. I didn't succeed but even so we do believe this can be done without much disruption to the local residents. Traffic, there is always any time we have traffic and we have construction there is an impact and it's something we have to pay attention to. We always joke about two seasons: snow and construction. Either one of those is slowing us down, but we can build under traffic. The photograph is from a test section that we built here in northern Iowa, where

we deliberately built it with traffic still flowing through the construction section. It meant a lot of management in terms of how we were only allowed to close down a couple miles of the road at a time. Traffic control with traffic lights and pilot cars was fairly involved, but we did it and there were no accidents and it can be done. Early opening is also possible. I've alluded to that is that if we need to get particularly residential grade traffic on back onto the the new roadway pretty quickly that can be negotiating. I've put the heading in here of effectiveness and just was a casual title for some of the things that we're doing a little bit different we are using AASHTO, ME is able to address design of overlays now that bottoms out at about six inches, so if you've got very little traffic you may want to look at other design tools and there are other tools out there and Gary and I can talk to those and Shree has a lot of expertise in that world as well.

We can optimize the mixtures. Again that's work that I've been doing, looking at can we make a mixture that delivers what you want using far less cement far less cementitious materials that we can reduce our environmental footprint without using a recipe-based mixture. The other innovation is this idea of stringless control. You can see there's a lidar or a total station parked behind the gator in the photograph and two poles sticking out the top of the paving machine, so that machine there's no string line on this construction site that machine is being controlled entirely by the total station and that actually means that you can be remarkably precise with the control, so that again, instead of adding an inch onto the pavement because you're worried about getting the thickness bonus, we can narrow that error down and make our systems far more efficient. We have large, very efficient very adaptable paving machines. Machines that can

do multiple cross falls. If we want to do the shoulders at the same time as the main cross fall as the main line and we can do full width if we have to. We can mount real-time smoothness measurement systems on the back so that we've got a far better control of knowing almost immediately what's coming out of back of that paver in terms of the smoothness at the end of the day.

And again the world's expert on that topic is the next speaker in this webinar. We can also use tools like maturity to be able to keep an eye on what is the performance of this mixture, when can we open it back up to traffic, and we can shave that down from a rule of thumb 24 48 hours if we've got the strength measured using maturity and the traffic can get back on in 8, 9, 10 hours. That's a huge benefit for both the contractor and the local community. We also talked, I alluded to safety a little bit earlier, but again, the less that we have to shut systems down, the better the safety is for the for the workers, and safety for the traveling public. And also you know somebody who hates getting trapped in traffic, it's really better for our blood pressure and our health all around, so again getting in fixing it getting out is a real benefit to the community as a whole. Alright, so how do we do this it's actually not very different from conventional concrete paving.

Use the same machines. We use the same mixtures. All we're doing is putting a slightly thinner layer now if we're using an unbonded system, we do have to think a little bit about how do we make sure that we get the unbonding that we want. The plan sets are simple, there's lots of materials and training and troubleshooting available both from us, from Gary Fick, from the TOPS team, and so a lot of information is available to help you get on top of this sort of question. Okay so what are some of the challenges? Why don't we do more of this and what we hear from the community is that we haven't thought about it before, it's not part of a conventional project management system. Innovation is hard. As engineers, we are risk averse and particularly from an agency

point of view risk adverse, because there's no upside to taking a risk in it going wrong. But we believe that we can provide you with the resources to help you understand that risk and make decisions that may have fairly significant benefits in terms of cost, time, reliability, all of the things that I've been ran rambling on about for the last 30 minutes or so. Many agencies focus on the surface condition only, and they're under political pressure, as many square feet or square yards or square miles as possible. The catch being with this is that a quick and dirty repair may also fall apart a little faster and so you may end up with a never-ending cycle of just playing catch-up on repairing a system. So we would encourage you to consider the full life cycle benefit. If I'm getting a 40-year system at a small increment of cost, are you not better off at the end of the day. And the other thing we can consider

with overlays, is that if the surface is the part that's deteriorating, we can put an overlay on with a couple of inches extra material which you can then go through and grind every 10 years so keep that friction resist up and still have plenty of structural capacity at the end of the day. Difficulty is identifying candidate projects and again that's true. And for people who haven't played before we have teams of experts who are able to come out talk to you to walk the pavement with you and to say this is a good candidate or this is not. Now this photograph is a candidate. Yeah no,

it's a little too far gone. But anything better than that, we can probably make it work somehow. As I said some of the other challenges include connections, dealing with getting under bridges, the extra work you have to do in service access, and again we have a lot of solutions available there on our website, the tools are there if you need help, feel free to give us a call. What about traffic do we detour do we shut it down and get in and out that's entirely up to you and again we can help you with that conversation. We can build an overlay pretty quickly as I've already said, but it's also possible to build under traffic.

In some ways that's an economic decision and it's also a conversation you have with whoever's living or working on that street how long are they prepared to let you shut it down. Either option is available and can be talked about it. A key part of all of this what we found is that life gets a whole lot better when you spend effort on communicating and planning. I think one of the war stories that was really interesting is that when we were planning an overlay in a rural community, one of the farmers was really hot about not being able to get home at night. The solution at the end of the day, the contractor paid for him to stay

in a hotel for the three days so he didn't have to go to his farm at all it was during the fallow season and so just providing a simple solution like that was more than enough to keep an impacted homeowner from being totally mad. So again work with your contractors. They often have really good ideas on how some of this stuff can be addressed. How do I get started? I've never paved before. Well like anything that we do in life, start simple, pick a fairly short section, something that's not very complicated, get help and there's abundant help available both from FHWA, from TOPS, from the CP Tech Center, call us. We can be there. Then once you've built it, keep an eye on it, how did it work out for you, was it cost effective, is it giving you the performance that you like? If so then yes, let's build some competency. Let's get your construction community used to doing this kind of work. Let's get your consulting community used to doing the designs. Then you can build this

process into your mix of fixes that you have for your system and we've done this on more than one occasion, on a number of agencies both city, county and state throughout the country. So what do we do, as I already alluded to a little earlier, the first thing is identify what type of pavement you've got to work with. Well that's not a hard decision. Assess the condition of the pavement and then based on that you can make a choice on how much effort do I have to put into restoring some functionality out of that existing pavement or am I just going to put a debonding layer and an unbonded concrete pavement on top. The debonding is in the form of

a thin asphalt layer typically about an inch or we're getting more and more familiar with the idea of using geotextile cloth sections that go between the concrete and the existing pavement and provide that layer of separation, the debonding, the sheer separation and both of them work pretty well and again there's just environmental and cost implications and time on doing both. So the four different systems that we talk about at the moment, we changed the tournament terminology about a year ago is concrete on asphalt, bonded or unbonded, concrete on concrete, bonded or unbonded, and you know basically the top layer, the differences are what have you got there and what is the condition of the existing system. And with that I'm done so I will hand the control back to Shree and let him introduce Gary."

Shree Rao: "Alright, thank you very much, Peter. That was excellent background on concrete overlays and really sets the stage up well for Gary's presentation. If anybody has any questions for Peter, as I mentioned before in the beginning of the program please use the chat function and send a message to me or to everyone and we'll get to the questions in the Q&A portion of the program. I'd like to introduce our next speaker. Our next speaker is Gary Fick. When I asked Gary for a

short bio, he literally gave me the shortest bio ever a couple of sentences. But Gary's name and experience really spans well past those two sentences. He's been really doing concrete construction for over 30 years and many many projects and has also done a ton of concrete overlays across the country. He's currently a project manager at the Transtec group and as a project manager at Transtec group, he has worked with multiple contractors and he didn't say it in his bio but I'm going to plug it in. He's the lead author for the concrete overlay

guide um that is produced by the CP Tech Center. So without any further ado, please welcome Gary." Gary Fick: "Thank you, Shree. I'm gonna leave my video off. I've had some bandwidth challenges here lately at the office and so I'll spare everybody having to look at my face just to be on the safe side with regard to bandwidth, but appreciate the introduction, humbled by that. So Peter's done an excellent job of outlining a framework for agencies to move forward with implementing concrete overlays. Now peter and I, I mean for over 15 years, he and I, along with the help of so many others and and those so many others basically taught me everything I know about overlays and they've forgotten more than they taught me, so a huge shout out to all the other folks that have been with us over the last 15 years on the CP Tech Center's efforts towards implementation and concrete overlay. So part of those projects and Peter mentioned this -- I mean we've got teams of

experts that go out and you know boots on the ground and walk you through scoping a project and I guess it's maybe we've had different mission statements all along or objectives -- but from my perspective, I mean the whole objective of of us doing this and I think TOPS is is the the perfect continuation of what's been happening, is to assist agencies with finding the appropriate application of concrete overlays for their payment preservation strategies. And I'll be the first one to show up to scope a job and say well just this is just not appropriate for concrete overlay, I mean it's it's too far gone or perhaps there's a better solution a better preservation solution and we still have an overlay down the road 10 years from now, let's squeeze everything we can out of this pavement before we have to overlay or remove or reconstruct. So I get the privilege of presenting some examples of concrete overlay projects from across the country.

And we are literally just going to hit the highlights. I don't want to get into the weeds on these. I think the intent here is for the audience to be able to look at at these projects and say hey that's similar to something we've got on our three-year program. Maybe we need to consider a concrete overlay solution on that. Maybe it's a potential strategy so that that's kind of

the idea it's not to get into the weeds and go through every single detail of these projects. So hopefully they're representative. I mean there's some geographic and climatic distribution to these. They vary from six years old to 14 years old, there are other case studies out there at the CP Tech Center's website where you'll find case studies of concrete overlays that are 30 years old. So these just happen to be let's find something that's that's fairly recent,

spans a wide variety, we've got different facility types, we've got different overlays. So Peter just kind of went through those. We've got concrete on concrete unbonded, we've got concrete on asphalt bonded, and we've got concrete on asphalt unbonded, varying levels of traffic volume and loading and then different approaches to maintaining traffic during construction. So let's take a look at these projects one by one.

First one is North Carolina and Yadkin County on I-77, so constructed 2007, 2008. It is concrete on concrete unbonded. The existing pavement a 43- year old continuous reinforced pavement. It was experiencing punch outs, ruptured steel,

faulting at cracks, it obviously was needing some attention. North Carolina DOT chose design build delivery method on this, that that fits, I've seen plenty of overlay jobs in our design bid build. There's nothing you know special that it has to be designed build this one just happened to be. So when we talk about the maintenance of traffic on this job obviously pretty heavy used facility, lots of trucks, lots of vehicles. So the approach was a median detour

with limited duration of one lane operation. So most of the project main to maintain two lanes in each direction. The contractor was allowed some windows where they were allowed to reduce down to one lane in a direction. The ramps also had some time frames they had a maximum 11-day closure. Now what's interesting about that is is the design build RFP had those ramps constructed in asphalt. The contractor proposed unbonded concrete on concrete unbounded overlay for the ramps to save time, so they saw this as rapid construction. In fact taking less time on the schedule with those 11-day closure limits than an asphalt alternative would have. Typical section is 11-inch JPCP,

jointed plane concrete pavement, on an inch and a half thick asphalt separation layer. Now really elegant solution to, and and Peter mentioned this a couple times in his section of the presentation, of how you do transitions, how do you match existing features so the bridges on this project actually were able to be jacked to the overlay elevation. So they raised the bridges by 12 and a half inches to match the 12 and a half inch raisin profile grade from the existing pavement, and then by specification, the entire surface of the concrete overlay was 100 percent ground. That was just a decision that was made in the design build RFP that they wanted in ground surface for smoothness for noise whatever it was but that's that's the way that went.

So our second project is Colorado State Highway 13, kind of north, well maybe central west, I guess you'd call it western slope. Kind of dry country out in Western Colorado, existing pavement was asp halt so we have a concrete on asphalt bonded overlay, the COAB. This asphalt was profile milled, so we're trying to optimize the volume of concrete and optimize the potential for pavements smoothness, so it's important to recognize that profile milling process so that involves collecting roadway profile data and then developing a proposed profile of the overlay which, given those two things, we're trying to find the best compromise between the potential for smoothness and volume of concrete that it's going to take to get there.

And we've got to maintain a minimum thickness of our overlay. We've designed for a certain number of ESALs traffic loading, whatever it is. So we're looking to find that that best compromise of concrete thickness volume of concrete which all boils down to cost and then also being able to produce and construct a smooth pavement in the end. So the typical section on this job is six inches thick, again, jointed plain concrete pavement with six foot by six foot slabs commonly referred to as a six by six by six. Colorado was kind of an innovator with

the six by six by six design. This project again was 2016. It was also an alternate bid so alternate bid concrete versus asphalt and in this case concrete was lowest cost alternative. Maintenance of traffic on this one, a little different than what you see sometimes. We've got a six-mile-long pilot car operation, so we're maintaining traffic in both directions using a pilot car constructing the overlay one lane at a time. The picture on the right if you can see it kind of shows that we've got pilot car and then and paver and on one side. Final smoothness for this project, average I RI was less than 45 inches a mile so really complete success there.

Third project is Blaine County Oklahoma State Highway 51. Again constructed in 2016. this was an existing asphalt pavement and again a concrete on asphalt bonded overlay application. This one was not bid alternate but went through a couple rounds of bid as an asphalt project and were rejected twice and then redesigned as a concrete overlay and finally awarded to that. Typical section is five inch thick fiber-reinforced concrete so again jointed plain concrete pavement six foot slabs by seven and a half foot long. Again this was profile milled so the idea is and you can see part of the roadway milled. The gentlemen Neyland in the the foreground here is actually the pavement was widened as well I think a couple feet on each side so those millings part of them were utilized to widen as a sub base under the concrete overlay. So just out of coincidence the guy in the foreground,

one of those people that have taught me so much over the years, he and I worked together for 15 years but he has been doing concrete overlays since 1984. And still doing it every day, wealth of knowledge and certainly appreciate all that he's taught me through the years. So maintenance of traffic on this one. Up to now we've kind of looked at different approaches for

how do we get traffic through a job. This one was actually closed to through traffic so let's get in here and and get out as fast as we can, close the roadway to projects five and a half miles long to through traffic, obviously local traffic maintained so property owners can get into and out of their property. So to do that, they you know kind of segmented the project to where they could get people in one way out the other way, but still have the road closed to through traffic. If you think about 90 days you know this the second bullet project completed less than 90 days, so you go bid opening, project award, pre-work meeting, mobilization, construction of the overlay, and then reopen the traffic all in less than 90 days. Whatever the terminology you want to use, whether it's you know rapid construction, accelerated construction, it fits the bill. So

my experience, first 15 years of my career was with a contractor and built a bunch of overlays, and I can tell you that when you get to go to an overlay job it 's like vacation. You are not fighting the weather. I mean literally unless it's snowing or raining you're paving. You're basically weatherproof and it just shows up and in the production you can make, in the in the time savings that are available when we look at overlay solutions like this. Another thing you know, I mentioned that the roadway was widened by a couple feet on on each side so you can kind of see on the left there all the drainage structures were extended to accommodate that widened roadway.

Fourth project is County Road in Iowa so Worth County, very north Iowa, 23 miles long. I mean this, you know, county is only 36 miles square so most of a county right 23 miles long. It was an alternate bid, it was awarded the concrete based on initial cost, a combination of initial cost and estimated life cycle cost. The typical section is four inches thick again JPCP, six foot by six foot slabs. The plan set was ten pages, so yeah maybe

it's a new technology to certain agencies but once an agency gets comfortable with concrete overlays, the project development and engineering is pretty straightforward. I mean we do not need hundreds of sheets of plans to go build a 23-mile long county road. It's doable with with only the information you need. I mean here's an outline, here's station to station, here's the typical section, make sure you get people in and out of their house that's tha t's about all it takes. So zero pre-overlay repairs on this old roadway. And no milling so whatever was there got overlaid with four inches of concrete. Now obviously it's not you know not high volumes of traffic,

but I will tell you the the loads from the agriculture equipment up here are not light so again it just did not require any pre-overlay repairs. Closed it to through traffic kept it open to property owners and then again 23 miles, 110 calendar days, and that roadways gone from old asphalt pavement to new concrete overlay open for the full length. Alright, the last job and I see quite a few of these now, not always an unbonded like it's presented here but this is an urban intersection in Salina, Kansas filled in 2012. So for Salina, this is the busiest intersection in town. What was interesting, they actually had in their their kind

of infrastructure plan another intersection that was going to be reconstructed in the following year and they knew they needed to do something with this one before that next project. So what do we do? What can we do? Kind of short time frame what can we do without disrupting forever what's going on with with the businesses around here and a concrete on asphalt unbonded design was a solution. Now it does happen to be an existing composite pavement so with the new terminology, the fact that it's composite, we just call it concrete on asphalt and this one happens to be unbonded. They did some partial depth milling so if you've ever done any work on on an urban intersection you know we've got a jillion things that we have to come back and match: elevation, whether it's curb and gutter, whether it's utilities, whatever it is.

We're pretty much locked into whatever elevation we were at so the approach was partial depth mill what was there, place an eight inch thick JPCP with 12 foot by 12 foot slabs. Maintenance of traffic on this one is really just like you build any other intersection. I mean you're staging it by quadrant and maintaining traffic all times during construction. You might limit the turning movement now and then but you know same as you'd stage any intersection construction. The entire thing completed in 45 days kind of see a before and after. Those are the project highlights and I really hope again that they just kind of remind you of projects you've ever had in the past and say hey we might have been able to do a concrete overlay there or you're looking at something in the future and possibly a concrete overlay is a potential solution for that upcoming project. That's the idea here, we don't want to get into the weeds about you know, what are the design details, how thick does it need to be, what's the fiber dosage, a lot of that information. In fact there's there's just

a ton of resources available at the CP Tech Center, at FHWA DOT. You'll just find tons and tons of resources related to concrete overlays. I encourage you to check them all out. Shree, it's back to you." Shree Rao: "Alright, thank you very much, Gary. That was an excellent presentation

and it really shows the different ways you can do concrete overlays in different situations. It really covered many different types of concrete overlays and it was exciting to see all those different projects. Again, if anybody has any questions please type it in the chat board and I'll have Peter and Gary answer those questions.

There's a few questions already on the chat board and I''m gonna ask those questions until we see more questions. The first one is from Bob Hackman who says won't IIJ, I guess that's the infrastructure investment and jobs act, provides some funds for use in looking at concrete overlays? This is probably not a question for Peter or Gary. I don't know if Sam, you want to take this question? Peter, do you know anything about the IIJA?" Peter: "I was kind of hoping Sam was gonna pick that one. I don't know a lot about it. I was actually looking to see if Leif was on but he's not here either. I'm not sure that I fully understand the question. I'm pretty sure that there will be

concrete overlays built using IJA funds depending on how the states tackle it. I'm not sure that any of that money would be available for investigation or promotion but you know that's the activity that you're doing under the TOPS program and that we're doing under our cooperative agreement, is providing the resources to help the agencies. So two answers to one question, Gary?" Gary: "Yeah, no. I really can't provide anything that

of a meaningful help regarding that." Shree: "It's probably more a comment than a question. The next question is from Thomas Tate. He asked how is widening accomplished? Gary do you want to talk about widening of a roadway when you do concrete overlays?" Gary: "Yeah, I can briefly and and I will say it's one of the most challenging parts of overlays when we try to tackle kind of integral widening with an overlay, things can get complicated pretty quickly. There's some some good guidance in a couple of the resources. First being guide to overlays the other being, I forgot the title, the plan details one Peter that Jared and I worked on. But anyway it goes through some pretty good details on on how you would approach widening

integral with a concrete overlay. But again, it is sometimes one of the more complicated things we do. So if it's your first overlay maybe you look for one that's a little easier, but it's been done a lot so it can be designed around and, again the devil is in the details." Peter: "Is it worth going back slide seven we actually had a photograph of a widening happening?" Gary: "Yeah we did. I'm not sure that matches up with the current kind of guidelines for

you know reinforcement of a integral widening and are some drainage considerations as well. In fact I think that that photo Peter came from one we learned a couple lessons." [Laughter] [Crosstalk] Shree: "Okay. Thank you, Gary and Peter. Bob Hackman has a comment about the American Concrete Pavement Association has a national map of overlay, so if anybody wants to check that out again go to ACPA's website. There's a question here from Z. Lootens working on project that is adding a third lane to existing two-lane each direction interstate. Considering using PCC pavement section for third lane and PCC overlay of two existing HMA lanes. What is your advice,

example tied untied wedge mill to match PCC thickness for longitudinal joint between new PCC auxiliary lane and PCC overlay? So, Gary. I'm not sure you got that but essentially how do you tie a new PCC lane to an overlay PCC?" Gary: "Yeah, so it's similar to a project I did back in '98 I think. '96 maybe where we had existing four lane facility we did an unbonded overlay on the existing lanes and then widened both to the inside and outside with additional lane and shoulder. I would say tie them just as you would if all of them were from ground up new concrete pavement, because what you're looking at that concrete on the existing asphalt that's an overlay. That asphalt is is simply a a sub-base course it's their support you want to be a little bit aware of what movement might take place between placement, of unless you're placing it all at the same time 36 foot wide say, what movement might take place between the the construction of the separate lanes. But I would say tie it just as you would any other concrete pavement."

Shree: "Peter, is there anything you wanted to add to that in terms of the movement and the friction, different friction you have between the different support conditions?" Peter: "Yeah, I'm semi wondering how much, yeah they are going to move differently and so you may want to consider how you can allow them to move without causing faulting. I'd be reluctant to tie them together too tight because I suspect you'd get some cracking coming through." Shree: "Okay, thank you both Peter and Gary. John Sudela asked Eric can you just move back one slide so people can look at the resources page? Here's another question, is there a maximum traffic or ESAL limit where you should no longer consider bonded overlay and use unbounded instead? And the question further says ACPA guide to concrete overlay reference suggests only up to 15 million ESALS for bonded. Peter, you want to take that?" Peter: "I'll defer to Gary." Gary: "Yeah, so I think rather than theory, and

I'm gonna get way out of my area of expertise with design. But what's gonna happen is if you have a a facility with with millions and millions and millions of ESALs, you're going to end up with a thickness of overlay which, it doesn't matter if you bond or unbond, so you might as well call it an unbonded. If that makes sense. I mean once you get above six inches of thickness, any any contribution you're getting by bonding to the layer below is is negligible. That upper

slab the overlay slab is carrying all the load, so I think it's just going to be driven by the ESALs and the thickness of the pavement you end up with. And if you don't have to bond, don't bond." Peter: "I would agree with that." Shree: "Alright, thank you very much. Greg Dean asked was this presentation recorded and will it be available for others to see? I can answer that question. Yes, it is recorded and it will be posted on Federal Highways website.

[Indistinct muttering] Greg Dean asks on the thinner asphalt overlays the six by six sections should the joints be sealed or left unsealed? Opinion?" Gary: "Peter take a stab at that? Peter: "I'll start. I think they should be filled. The reason being that if you leave the joint unsealed and water is able to transport through the joint, you increase the risk of stripping of the asphalt below the concrete and then you've got a support issue. And you may have a failure because the concrete's got nothing to sit on. So you know seal or fill,

you know it's another debate altogether, but I would like to keep the water out of the system." Gary: "I agree and and I guess I'd add just a little bit. I mean so if you go back to the very pre-history of of thin concrete overlays, where we ended up with these small slab sizes, the approach was not to seal. And we've learned plenty of lessons, especially in wet freestyle environments, that the benefit of filling those joints is worth the cost of filling those joints if you're not in a wet freeze thaw environment, I think we've also seen some lessons learned with just simply filling of incompressibles in those joints and some premature distress. So I would agree, fill the joints." Shree: "Okay thank you both Peter and Gary. I did want to mention to the participants that

2022-03-28 03:50