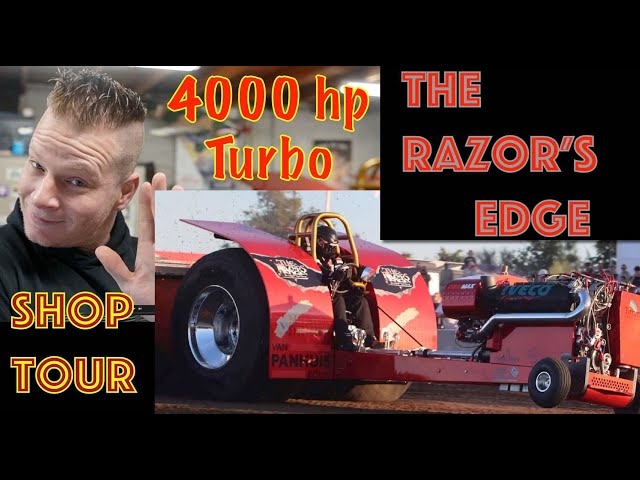

Visiting the Razor s Edge Tractor Pulling Team - Turbo Methanol Iveco - by EUSM

hello everybody we are in Holland and I had to deliver some T-shirts to home so I just grabbed the opportunity by the hairs we say in Germany and stop by at Alfred Herman hi hello so Herman is a modified puller in the Netherlands yeah we have not covered much of the Dutch circuit yet because uh they are on TV and they have different rights since we can't film there yeah true but if we're here then we might as well have a little look what he's got to show us so as we said you're Herman hi hi so you are how old and where are we and yeah just tell us who you are and what you're doing yeah I'm we are in four thousand near the center of the Netherlands I'm 25 years old during my normal life during the week I work as a at a company called DMX It's only three kilometers from here we're building engines for marine applications most of them are car engines that we get ready to put in boats and we also do some developing of our own engine a V12 diesel 6 liters and at the company I assemble engines testing engines and also some of the time that's standing behind the CDC machines laid Mill to get everything yeah ready yeah you are kind of uh famous I've gotten several messages from other people already that there's Hammer guy he's doing amazing stuff on the CNC badly enough you don't have one at home you'll probably probably do everything at home at the workshop yeah it doesn't make sense but if we just see over here you can already see there's lots of CNC stuff on here super nice director come on over tell me something about it because this is different totally different yeah is it different yeah maybe maybe it's a live modified tractor we call it here in the Netherlands it's two and a half tons so we're very confused about 5500 pounds yep it's powered by an Italian engine uh inline six iveco out of truck it's a refrigerator 10. 10.3 liters of displacement which is like 600 something yeah somewhere 640 cubic yeah I think yeah in that range no still with the stock head you got the overhead cam four miles a cylinder we change this a bit uh why because trick pulling and get some horses out of it as you can see there are no injectors in it anymore we got a ignition on it to burn methanol from the back we got three turbos in two stages to feed the engine the engine itself is pretty heavy why we choose for that engine the main thing is the technical part behind it I don't know if you can see it but this engine is already girdled from here just the center line of the crank and this main part is a complete girdle that's buttons of bolts to the bottom of the engine and as you know a lot of people International as John Deere they have to make Humane caps and make a girdle beneath it and that's already stuck on this engine yeah Italian that's just yeah use the last I built a loss what do we change more normally the Drive of the camshaft is behind the engine there's a big aluminum cover with a lot of gears in it also for a fuel pump and compressor and all that kind of stuff we took it off milk the Bell driven okay on it yep also put here a little box with gears on it to get our fuel pump running and behind that there's oil pump running to get the engine also as far as mounted on the front and FD on the front to get some weight on the nose and what do you get more you added internals uh forged pistons aluminum rods counted weighted crank stuff like that another cam is in it we machine it by ourselves get it grinded by a company yeah most of the parts as you can as you see are built by ourselves why that's the only way we can afford to do the sport I mean luckily enough we got a sponsor and a company where I work we can use the machines it's always nice sometimes it gave you uh some some people say CEC will take less time it's true but in the end you want to make it nice and then it starts to take time and sometimes you make insane parts or takes I don't know if it takes but you want to make it nice and that's the main thing about things you can make it nice but it takes some time it's the same thing we go back we gotta hear our uh Shield protection yep that were two solid blocks of aluminum you also can use a tube and slide it over each other but I've got a friend who said a CNC mechanic will start to make everything out of Bill and not even think how we can make it cheaper no that's but it ended up does look nice yes sure first thing that I would wonder is I know why you did it but most other people probably don't why do you have the turbochargers in the back most people put them to the front yeah this whole idea to get weight on the nose when we got started with this engine we got a build we just put a skill on the front turn it up first put a charges in the front engines behind it there's a certain amount of weight and then we change them and it gives us about nearly 100 kilos more on the nose when we build it like this then put a durable judge in the front and in the end it's kind of uh for maintenance like working on the cam or stuff on the front it's easier for sure so adjusting your clutch it's a little bit harder that's the other part but so what do you have to do more just on the front door adjust the clutch usually the clutch now yeah sometimes both because at the engine at the time is not running like it should be and then you make changes and to adjust it every time because you slip it a little bit more maybe yeah you're on a clutch pedal yeah you do yeah it's uh clutch pedal to build boost but this is also a fiddle clutch it's like a car where you want to run you have to release it okay it's a better assistant yeah why do you choose with that one because our starter is also in a drive line yeah true with the central focal clutch then it would be difficult to start the engine yeah to make you do it here definitely I mean the engine runs you just take it off and off we go yep to save weight really good so I just looked at the rear so that's very light so everything's homemade there I guess is it most of it yes what is it there's an sqhd or uh no it's a marital 20 on the 45 okay yeah you know it yes I do I report it from you yeah okay yeah for this clutch 11 inch with a molinary speed up one and a half times from there it goes to the reversion then it goes to the meritory center section and from there it goes to see this planetary and from there to a set of guys rims and they are inside a set of meters powerful tires and those have uh 56 Lux 56 yeah yeah um I don't know the degrees you know three millimeters of yeah but a little bit more Lux than the Firestone yeah yeah that's the thing you can do with the meters just say how much you want to have but yeah and you buy them and sorry The Cutting guy says how much you want to have yeah no idea no idea I thought I recommend this yeah something like that yeah yeah see this planet here also with some uh homemade covers it's always the nice thing about CeCe put some aluminum in it roughly so the nice thing is if we have to make 20 more then yeah you know where to go yeah yeah that's the easiest way sure is it's light most of it's home built yes like throttle you know a lot of this little piece of aluminum gear shifter what's the weight of the tractor without the engine do you know that nope I have no do you know how much the engine weighs also not damn it no no because this is actually a super light tractor um which of course has to be being 5500 Parts but the engine is also super heavy I think roughly said the engine is about uh 1000 kilograms somewhere in that area yeah I guess so like 2200 pounds so yeah because I would think this is the current state of the art of building a chassis and and rear end in Europe as well then I saw you run an MSD yeah so people will wonder how this is for an eight cylinder how do you do that two gears on it to get it running on 75 percent otherwise you've got too much Sparks on different locations yeah but we don't want to have them we need a certain amount of combustion yeah individual new distributor cap yeah we started with the electronical ignition the msd8 Dual ignition but during the season we had some trouble to get the engine running well and we had ideas well maybe it's the ignition we need a little bit more power so then last time we mounted uh msd20 we can borrow that to get some testing but then we put some uh bigger fuel nozzles in it to avoid if it goes running well it will be running too lean but then I made a little mistake so we put a little bit too much fuel in it so in the end we couldn't get it off the line just around the engine with fuel so uh the mc20 will get back to his original owner and we bought this one the 44 you know good afternoon it will sure ignite everything yes just timing those things isn't easy yeah it's like impossible I like them you have to set it to a person does to make a little Mark on it so you can see that you yeah actually on the right yeah with an external trigger uh nope nope you could off the crash yeah really it's still there because we run there yeah but I think these these these can handle that too yeah you can also end it yeah there are different opinions about that so say in the low RPM there are actually more accurate with the trigger in an high RPM you can use the one that's uh inside it again if you have to worry about one degree ignition timing in a turbocharged engine being worried about power not about destruction yeah you're not on the right path yes we got there yeah something you wouldn't know yeah I do know that's funny how many stuff was in the shop I already know so we got an ALICE in half an Allison so yeah without crankshaft yeah yeah all the together to get some size of it uh well this engine for not for static display you want to get it running to make some ground runs on it so that's the reason why there's an F-Type probably on it yep that's where the propeller used to go yeah and during the time I already also got a big propeller how much for this but uh nearly four meters quite yeah yeah it's a big one so you're going to be one of those guys that puts these on a little trailer and yeah moves there yeah let's make noise we also had the idea maybe of to put it on the track so that there's a reason standing now here in the shop can get some measurements but in the end we won't do that yeah you had a V12 tractor before yeah with a trans mesh yeah still a picture up there I have some video on that that's very uh and where you got famous with by splitting the complete engine in two pieces yeah we started with that one uh in 2012 as our tracker off for ourselves we've been into pulling since uh dad went as a spectator to events in the early 80s with his brother-in-law then came family became a team member of the Beavers somewhere in the late 80s don't worry became a team memory somewhere about 88. I was born in 86 so I never knew better than Cricket pulling yeah I know how that goes yeah she's been there done that and that became yeah like I said team member been there till 2003. and I always been there running around helping what I can do then that quit I started do some RC tractor pulling micro pulling also became Dutch Champion with it got a little tool drive tractor with a little four-stroke engine on it later Builder modified with two two short engines on it at the same time I was a team member for a combo diesel director and helping them out later became uh let's let driver for the compact diesel and that still mentions you want to got something for yourself and then said oh I may want to build a mini rod but yeah and he likes a V8 because he was used to V8 of the Chevys of being Weaver then I said ah you want to do something we have to be something else that the rest and make something else and then was looking on the internet and found an engine in the north of the Netherlands and that was the Russian V12 bought it for a few bucks and then from there we started bought the old chassis of the red diamond that was the first uh Griffin powered tracker that was running the two and a half tons we took that engine uh there was also a diesel engine we converted to methanol with a supercharger on it from another Russian engine because that engine was naturally aspirated put a supercharger on it for Manchester and that one gave us a lot of troubles a lot of troubles because here's some mild compressor Wheels yeah hanging the top one is the original one that one had a hard life with a big backfire it lost his wings that one was only 60 meters old I ruined it in gums in Denmark uh 2040 season because yeah the top one's original one we didn't have a spare one we contacted some guys of a Danish guy who can help us with it to supply our one but they ask a lot of money for it and it was only three weeks before the season started that's it so we got a big problem going on then we came in contact with Roloff Sodoma guy from the south and uh he said oh we can do one we can make it by ourselves so uh Roland helped us all those days because we had three of them he was in one season and then everything during the season where exchanges and changing every time the thrust bearing uh got out you know that sorry yeah these elephants like to love to do the same thing yeah and because there's a little story maybe I can I know if it's interested of course you can see true to veins there are those little holes yep they call it uh I call it compensation yeah pressure relief more or less yeah because yeah you got a whole you see a compressing air yeah and also stuck in the air from here yeah and to afford to get a lot of trust pressure they make those little holes in it so we can balance in the center but yeah probably that didn't work out as it should be because we broke a lot of bearing during the season and every time because we didn't have uh new compressor Wheels we machine it down again and in the end it was working we can make uh multiple pools with it without changing bearings and I have to machine the wheels and then we have the opportunity to give a demo in Denmark and gums they would say oh for the next easy one too make some changes so we made a new one with the higher things because it did yeah that wasn't machine during the season then he got the bumpy ride foot off the throttle go back on it again uh bend the drawbar couldn't make a decent run and then shot it down at I don't know 65 meters and then there was little smoke coming from from the engine and looked inside the little as a result of 60 meters of testing yeah yeah that's the life of a pool man yep and but that was not when you blew the engine no okay then we knew that this wasn't the right way to go to make some horses and then we went to the turbo charges made a new build a new engine because that engine on the picture is the the industrial version It's a cast iron block yeah they have aluminum too yeah yeah and then we want to uh improve something so we bought a license built police engine out of it it was completely made out of aluminum put to durable charges on it had two two events struggling a bit to get the fuels setting right because yeah that's a whole different story yeah story then uses some Georgia and then in modern 2015 we got everything shorted well it's getting off the line and then the Driveline had a little issue lost connection and then they'd make and then you made the Russian go fast as he didn't like that yeah 5375 RPMs and then from valve cover to sump the right side of the engine was completely splitted Luckily everything will stay together because we disassembled the engine and it was correct from the starts of the main bearing goes up into the block everything was correct normally you have to torque those bolts down about five and a half hundred newton meters and after the pool we can release it with the hand yeah damn it because everything was stretched and and then we got uh some more spare parts to build a new engine and then a guy showed up said hey I got a vehicle engine shop just take it because it's standing for my foot you see here in the nails yeah and see if you can do something with it and then yes we thought we could make a little bit more power and maybe I don't want to eat here but in the spare part situation is a lot better I've heard that a lot of the guys that run the transmission at the moment have a horrible time getting parts because they're getting all getting fried in Ukraine at the moment yeah it was the same time and they we're running into the career yeah it was in the same area we blew up the engine yeah and so then we thought maybe it's easier to go another way yeah and this engine is maintains way easier you know that if you want to take yeah 312 just or even they're just buying parts just a simple things like I don't know a crankshaft some bearings and some very few bucks you can order it tonight and you get them tomorrow yep exactly this uh the main thing about it yep and in the end we don't regret it yeah I mean it's nice to run with these old v12s but they're not making them anymore or at least the ones that are still make they're still blowing up at the moment but uh yeah I mean this is also nice it's also something different and as long as you can be competitive with it why not you don't have the money to be in it you can be honest about that yeah but in the end we like the sport we had the possibility of me parts by herself and then make a tractor look nice run it and just compete in the sport exactly it's our our main goal yep we are at Hammer's company now we just found this tell me what is it it's a fuel pump for a common real system you build it also here there are some truck pullers you use it use a comma wheel system and in the early days they run the original pumps but yeah they need a little bit more fuel and need some nice parts and then we machine ability fuel pump okay this is for a six cylinder we also have an eight cylinder running he's using a Scania engine and they can supply how much fuel for the horsepower you think numbers I don't know the numbers by my head okay but it's the main thing this has come a real pump and that's the advantage of a common wheel pump instead of a mechanical pump you only only need to fit the rail injectors but you still have to have a certain flow that it has been able to deliver well it takes a lot of stress out of the components and we this one has been on this bench and it takes uh more what's like more than of less than half the power of you need to run a mechanical pump okay that's nice because in the big pumps that's actually already takes a lot of stress I could guess that's getting into 100 200 horsepower if not even more yeah the the test bench it was a meter and it takes 100 amps normally to drive a mechanical fuel pump and this one takes only 40 or so nice cool this is where they where Hammond works we got another lathe here this is a really big one oh Big Friend it's nice when you got a big drink yeah a big machine sometimes yeah that helps so then we here got one of the Angels they built here D-Max B12 yep it's all something more about it it's a V12 C3 six inches of displacement available in several horsepower ranges started at 600 you can go up to 900. uh based of using the BMW heads the new type of the n47 when I'm right hmm the block himself is our own product of course the block so you get the block caster and then yeah all manifolds so we kind of made a V12 BMW diesel yeah nice the three liters I think the American Car magazine I'm not sure which one called it the tire shredder laughs of course they got so much trouble that's nice yeah and more engines yeah this is also in development Rover engines okay yeah standing over there this one's already equipped the waterproof manifold hard to see because nowadays yeah I would say this is a brand on it yeah dmax water cooled cute I'm not cute but there's some of his Bros cool first started out with a village lock machine out of the soft feet of aluminum but there were so many people want to have that market he found out it wasn't the right way to go no it takes a lot of too much time as soon as you get into the numbers then casting is the way to go yeah definitely how many you make of these or build of these in a year they're still developing quite a bit so what's what is the demand for this engines so high because they take less fuel or what's what's the point lightweight compact normally where you have a boat engine or a green engine that works at six or seven on a horse you came into uh truck engines they are yeah right yeah yeah the lower pair and stuff right yeah also there's four or five thousand RPM possible nice small package real light it's only 350 kilos so yeah and it's a V12 it says different song sounds a little bit better than a truck engine yeah so that people are interested in them oh cool small package lightweight horses yeah nice oh great thanks for showing us that yeah okay I think that's a nice little look behind the scenes here it's not that much to see it's just one character but whatever a little story some here and there that's nice well thank you yeah and yeah I will let you know when it's going online and yeah see you then bye-bye thank you

2022-11-07