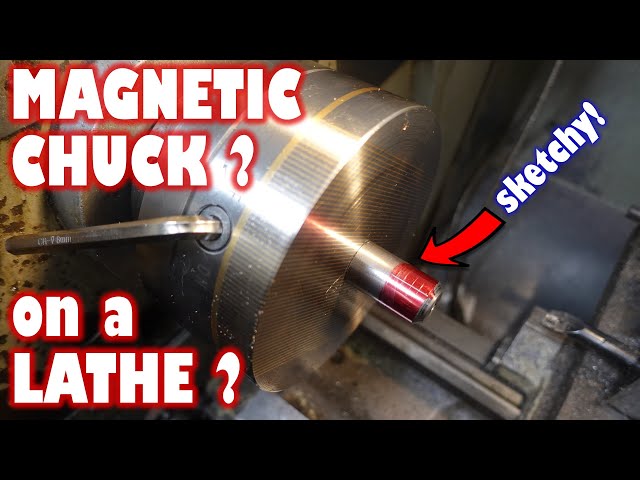

Magnetic Chuck for Surface Grinding on my Lathe

neil what are you up to is that a magnetic plate i hope this isn't going to be one of your sketchy setups don't twist too hard why not turn it off try turning it off more crikey i've got a regular need to make thrust washers of a very tightly controlled thickness and flatness but i don't own a surface grinder however i do have a tool post grinder for my lathe in one of my increasingly rare lucid moments i decided that rather than having a surface grinder table moving forward and back why not have it go round and round especially as most of the parts i need around anyway and then drive a grinding wheel across the face of the part with a cross slide using the y axis of the lathe to set the thickness it might have ended there but i was looking for some parts on a website and a very attractively priced fine pitch round magnetic chuck scrolled up the screen i was hooked but i'd need to make a d1-4 mount and pins and all that malarkey a quick google to find the dimensions triggered the NEIL IS SHOPPING AGAIN algorithm and bam! an advert for a very attractively priced part finished d1-4 cast iron chuck back plate hove into view of my mouse hand it would have been rude not to click on the buy me now button wouldn't it the chuck had a shallow 100 millimeter diameter inset but no mounting holes the magnetic face of the chucks made from a stack of alternating iron and brass plates clamped by two transverse pins which are machined flush with the outside face it probably has the usual internal cam system and magnetic magic but i wasn't in the mood to dismantle it to find out a quick test with a tiny toolmaker's vice showed a remarkably powerful grip and some considerable residual magnetism i guess the holes in the mount were intended to take 5/16 inch cap bolts because they were about nine millimeters diameter trying to decide where to make the threaded mounting holes is amusing i've got to avoid the two transverse tension pins and the six clamp bolts and the actuation mechanism i picked an orientation with two holes halfway between pairs of clamp bolts and away from the actuation pin and lock pins just hoping there isn't anything delicate in my chosen spots fingers crossed firmly step on the mount's about 131 millimeters diameter it's also a little too tall spindle nose hygiene is so important neil that sounds like an advert for intimate wipes i did the usual setup for camlock chucks fitting the pins so the reference line was flush with the face of the mount checking the fit to ensure the cam locks had about half a turn of travel one of them needed an extra turn once sorted i fitted the set screws which are there to prevent the pins from falling out but still allow a bit of wriggle room so the cams can seat nicely against the curved sections machined into the pins before doing any machining of the mount i thought i'd better check it for axial and radial run out using a dial gauge on an Noga arm with a magnetic base face run out's pretty good at 15 micrometers, that's six tenths in imperial but i can do a lot better than that run out of the raised step's not important but it isn't very accurate at the moment once machined it should be concentric to within a few micrometers just for completeness i'm also checking the bore run out and the face of the raised step which i'm going to machine off soon don't know why really seemed like a good idea at the time perhaps for a self-inflicted false sense of security yay measure all the things as the meme goes next steps to machine the face of the raised section then start reducing the diameter of the boss down to 100 millimeters as the fit's critically important i'll do fine finish cuts to get the fit exactly right it's not trivial to measure the size of that housing on the chuck to great enough precision so cut and try will be my tactics when you overshoot the mark there's plenty of meat on that mount so you can try again loads of times ha ha huzzah it's a splendid fit time for a bit of a clean up to break any sharp edges then we'll be ready to drill and tap the mounting holes in the back of the chuck i'm taking a fine skim off the outside simply to pretty it up a bit there wasn't much run out anyway i'm doing a quick debur of the central hole just so that i don't slice my fingers again i do love these sure shot sprayers i got one after i saw adam booth using one product placement is a marvelous thing cost me a fortune to import it it's pneumatic so i part fill it with brake cleaner and then give it a squirt of compressed air instant aerosol not sponsored lol hey neil hack my avatar an add a Quinn Dunki cap and safety specs i wanna be a cool kid uh nope made sets of four dots with my gorgeous starrett automatic dot punch to prevent idiot mistakes so the chuck mount and spindle nose will stay in the same relative positions even if i take it to bits to fiddle with something or other there are four dots on the spindle nose of all my other d14 mounts it's all about repeatability the holes in the mount appeared to be on 142 millimeter pitch circle but i wasn't prepared to trust the positional accuracy of whoever drilled those holes so i clamped the chuck to the back plate and used a 10 millimeter transfer punch to make a dot where i needed to drill the holes in the mag chuck off camera i drilled the eight and a bit imperial millimeter holes out to 10.25 millimeters it did not go smoothly there was lots of swearing including such choice expletives as bleeeep bleep bleeeeeep and bleeeep, not advertiser friendly i'm advised the body of the mount is pretty tough stuff so i'm using a center punch to make the dots a little more obvious although i use the transfer punch to make marks in the right places i'm still doing an idiot check after all there's an idiot at large in my shop and that looks fine actually one of the holes is a little bit off so it's a good job i marked the exact orientation isn't it haha you're fooling nobody you straight up forgot now you'll have to guess which way round it goes good luck with that right as a final idiot check i've calculated the radius of the pitch circle from the distance between the dots and it actually matches up with the real radius i might have to have a little sit down after all that arithmetic at this point i made a strategic error one two three blocks are great nice and flat and parallel except they're also full of non-magnetic holes can a thing be full of holes the chuck being magnetic can hold itself down while it's drilled and tapped except for all those flipping holes reducing the grip a bit still i got away with it just i used a wiggler to set the spindle directly over the center of each punch mark using a c-spanner to center it very precisely it's ancient technology but it's self-correcting and totally idiot-proof unless you try to align it using your fingers just don't the sharp point drops in nice to the center punch mark and you can see a tiny deviation if the dot isn't right in line with the spindle discretion being the better part of valour and this chuck not being inexpensive i used a center drill for once instead of just going for it with a stub drill see i can be sensible on occasions the tap drill for m10 by 1.5 is 8.5 millimeters so i used one of my cobalt stub drills which worked nicely in this material i set a stop at 21 millimeters this is just a debur rather than a full chamfer to clean up the edge of the hole so i can use the depth micrometer to confirm how deep the hole is call it nominative determinism if you like but the name does kind of imply that's what it's for depth micrometer it's apt Moor and Wright solid British made up the road in sheffield actually i like my mitutoyos more sorry sheffield well that looks like 21 millimeters to me a nice fat chamfer on each hole should prevent any distortion of the face of the chuck when the threads are cut i used an m10 spiral flute tap to start the hole using the chuck on the mill under power and then finish the hole with a hand tap wrench and uh spiral point tap to complete the thread the lovely brown earwax stuff CT90 which is normally the consistency of grease but it's been so cold in the shop that the dratted stuff's more like candle wax although a less attractive colour i always think the chips that come off spiral flute tap should yell WHEEEEE sadly i've snapped the cheap m10 plug tap that i normally use to do a finish cut on the last two threads of blind holes must order a new one i want to get these cap screws to fit with the maximum possible thread engagement without them distorting the brass insert or hitting anything important so 21 millimeters is the maximum depth and about 18 millimeters is the best thread depth that i can achieve i'm measuring each cap screw to be totally certain that they'll bear on the counter bores in the back plate rather than bottoming out in the holes after a trial fit i found the heads of the cap bolts i'd chosen were too large for the counter bores there were also a teeny bit too long it appears my luck's running at its usual level i held them by the threads in a 10 mm ER40 collet and machined the heads to 14.6 millimeters diameter so they'd be a loose fit in the counter bores and then chamfered the corners a little after sorting out the heads i grip them tightly in an er 40 collet and neil we've already spoken about your sketchy setups this is not going to end well if you're as clumsy as usual as i was saying before i was so rudely interrupted i carefully removed three millimeters from each bolt and chamfered the end of the threads nobody died no parts went into orbit no tools were ruined for a change it did scream a bit sadly my lantern chuck's too small to take m10 bolts i'd be hugely cheered if you could prod that like button it really helps me a lot having failed to have any disasters i gave the threads a good polish with garryflex abrasive rubber Cratex or bright boy would be a much better choice but i've got loads of Garryflex in rather fetching autumnal shades or is that fall shades mostly mud brown anyway it's always safest to run the lathe in reverse when polishing threads so the abrasive and your fingers are pushed away from the whirly finger mangler note the nakedness of the hands no gloves for anyone to complain about this is one of those cases where even flimsy gloves are definitely not advised sorry i sounded like an "elf an' safety" nut for a moment there let's go and do something dangerous off camera to compensate i stoned the rear face of the chuck to remove any burrs then cleaned it very thoroughly to remove any remaining abrasive using brake cleaner and compressed air same treatment for the mount if i had any marketing sense i'd label the next segment asmr peace and tranquility pink noise and relax feel that tingly autonomous sensory meridian response well as the late john peel once said you couldn't possibly talk over that could you hey wakey wakey oh heck i nearly nodded off there right i've mounted the completed chuck so let's check the run out first the mount looks like 30 micrometers that's a thou and a bit for anyone listening in the 1950s as expected the peripheral run out's not exactly stellar but i'm not going to fix it it'll never be spun fast and the internals are probably out of balance anyway the face is a critical element that really must be flat and perpendicular to the lathe axis so i'm taking a fine clean up cut using a polished carbide insert off camera i cleaned the surface and stoned it run out looks reasonable this is after i removed and replaced the chuck twice to check for repeatability i reckon less than two micrometers or about a tenth whatever that means i found a two inch square by half inch thick piece of cold rolled steel deburred a face degreased it and put it in the center of the mag chuck that ought to be a decent test of adhesion and what happens with interrupted cuts i stood well back from the danger zone wore a hard hat with a full face guard and kept one foot on the emergency stop brake bar then depressed the lever on the make-it-happener it machined perfectly so i de-energized the chuck remove the part deburred the machined face and fixed it back the other way around roughly in the center of the chuck stood well back cocooned in my ppe and lit the blue touch paper once more it machined perfectly with a nice finish quick check with the dial gauge showed no significant run out so i checked the thickness of the part at four places where the cut was continuous the mic showed around five micrometers of variation across the surface i tried fixing the block near the edge of the chuck face and spun it at 750 rpm with ppe and a polycarbonate shield it worked perfectly even at 750 rpm this is definitely not intended for a use at any more than about 80 rpm for grinding but it's good to know that i can also do machining so long as the parts are significant size and perfectly flat on the lower face throwing what little caution i have left to the four winds i've protected the way, fitted the tool post grinder and fired it up with the lathe at 275 rpm and the grinder at 10 000. as well as covering the lathe ways i'm using the shop vac to suck up most of the grinding dust and sparks i'll make a proper fixture for the vac pipe at some point in upcoming videos i'll make a super glue chuck around 120 millimeters diameter with a sacrificial aluminium surface on a smaller d14 mount to hold very thin steel parts that can't be gripped with a mag chuck and stainless brass copper and aluminium parts that can be glued but are non-magnetic after that next job's going to be a vacuum chuck to hold dielectric plastic parts such as lenses and Fresnel Zone Plates that finish makes this little project worthwhile the grinding wheel i used was slightly unbalanced so there are some harmonics the real parts will be done with a much better wheel and spindle once i get it machined lots more projects are in the pipeline if you'd like an irritating reminder when the next one's published please consider subscribing and clicking the bell i know asking is unfashionable these days but then so am i

2022-02-23