Understanding the Tesla Model S Front Motor

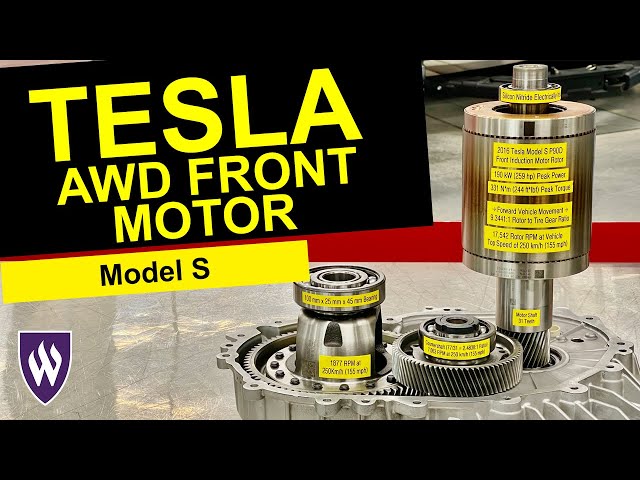

Hello, I'm Professor John Kelly and this is the weberauto YouTube channel today we are going to look at the front-drive unit and electric motor from a Tesla Model S. now all of the all-wheel-drive Tesla Model S versions up through 2018-2019 somewhere in that range use this same front electric motor that we're going to look at today. For 2019 at some point, I don't know exactly when that changed maybe some of you do and can put that in the comments but Tesla announced that they would be putting a permanent magnet rotor based electric motor in the front of the model s and from what I can tell from reading and looking at used parts on eBay the front motor that they put in the model s is really the rear motor from the Tesla Model 3 just put in a different housing to fit in the model s in the front now I could be wrong on that but it sure looks suspiciously the same before we dive into the front drive unit and electric motor for the Model S, I want to show you all four rotors from the electric motors of the model s and x and then the Model 3 as well if you purchased a rear wheel drive model s you receive the large rear electric motor if you purchase an all-wheel-drive model s then you've got two of basically the same motor one in the rear and one in the front they're in different housings but it's the same motor has the same internal parts the same power ratings if you got the performance version of the Model S in the all-wheel-drive then you had the large rear induction motor in the rear and the small front induction motor in the front and then for 2019 Model S you got the rear large electric induction motor and a front permanent magnet motor so those are the different combinations these three rotors right here for the Model S and X now if you get a Model 3 then you have the rear motor is this has this rotor right here which is a permanent magnet rotor and I'll have a different video on that coming up and then in the front you have this smaller much smaller than the Model S induction motor in the Model 3. and i don't know what they did in the Model Y yet from what I've read and seen it's the same in the rear and in the front, it just has a different rotor design that doesn't have a copper core it uses an aluminum core but i i need to get more information on that that's just what i've seen and and read so here are some additional photos showing you a comparison of the tesla model s large electric motor rotor and the rear electric motor rotor and then here are some comparison photos showing the Model 3 rear electric motor rotor to the model S performance electric motor rotor and the front induction motors for the model s and the model three okay I have completely disassembled and cleaned all of the parts for the Tesla Model S front-drive unit with the small electric motor the empty housing here has a few things to look at we've got places for three bearings just like on the rear-drive unit that we looked at a few months ago we have some holes right here for the three-phase cables to go through from our stator to the inverter on this side and then on the other side this is where the inverter itself connects there's a removable plug in the bottom of the case that lets you go in and disconnect the cables from the inverter to the stator assembly this plug is normally bolted down and it has this tamper-proof tape on the outside of it that if you try to peel that off it'll show that it has been removed and that may or may not affect your warranty status depending on who's doing the work okay so the front-drive unit needs a differential to allow the front wheels to turn at different speeds when you turn corners this uses just an open style differential which means that there's nothing to try to force the wheels to turn the same speed there's no pro posit traction or limited-slip or anything like that the vehicle does have traction control where it uses the brakes to act like a limited-slip differential but there's nothing in the differential itself to act like that now I wanted to compare the front drive unit differential to the rear-drive unit so let's bring in the one that we had in the previous video and we'll do a comparison here so the rear-drive unit has a 213 millimeter diameter ring gear that's 50 millimeters thick the front-drive unit has the same 213 millimeter diameter ring gear but this one is only 40 millimeters thick so it's 10 millimeters less I had several people ask why is the ring gear so big and why are these bearings from SKF so big on these differentials and it's because of the torque multiplication if that takes place with gear reduction if we have an electric motor that produces all of that torque and then you run it through gear reduction the the torque delivered to the axle shafts the cv shafts and the tires is basically your motor torque multiplied by the gear reduction gear ratio okay so the bearings must be large to be able to handle that amount of torque the gears must be large because all of that torque is transferred one tooth at a time so if you're transferring all of that torque you need a big tooth gear tooth to be able to transfer that the front electric motor on the tesla model s isn't as powerful as the rear motor so we can get away with a little bit thinner of a ring gear they both are bolted down with 16 bolts and yes I made a mistake in my previous video and I apologize to Nissan leaf people and those that caught my mistake I said that the ring gear on the Nissan Leaf was only bolted down with six bolts I was wrong it's eight bolts I knew it was eight I don't know why I said six but anyway I apologize so we've got 16 on the front of the Tesla Model S 16 on the rear pretty much the same bearings. this bearing here is 100 millimeters by 25 by 45 this is the exact same bearing these are the skf explorer series precision bearings made for high speed operation the front will be only rotating at 1877 RPM at the top vehicle speed of 155 miles an hour and that is very close it's actually it's a little faster than the 1841 rpm that the rear motor would spin at okay you might be wondering how how does the front-drive unit end up spinning faster than the rear-drive unit if you look at these photographs here of the tires and tire sizes from our performance model s you can see that the rear tires have a tire size of a 265 35 zr21 and that gives them a diameter of 28.3

inches or 718.8 millimeters if you look at the photograph of the front tire and tire size here you can see that it has a tire size of a 245 35 zr21 so these both tires use 21-inch wheels but the shorter tire in the front with the 245 size is only 27.75 inches tall or 704.8 millimeters tall that means the front tires are 14 millimeters shorter than the rear tires which means that they will spin faster okay so let's get this rear-drive unit differential out of the way and we'll take our front drive unit differential and set it down in the case there we go the ring gear here has 79 teeth on it compared to the 78 teeth of the rear-drive unit that we looked at in the previous video okay here's the countershaft for this front-drive unit it has a counter driven gear with 77 teeth on it and it has the pinion drive gear for our ring gear over here with 21 teeth and the 21 teeth driving the 79 teeth of the ring gear gives us a gear reduction between the counter drive gear and the ring gear of 3.7619

to 1. now just a quick comparison of the rear drive unit performance motor countershaft to the smaller front-drive unit you can see they're very similar the bearing on the front unit the SKF bearing on the front unit is a smaller bearing but it has the same rating as the other one over there this side of the bearing is the locating bearing it has this plate that bolts it into the case and holds it in place so as the gear expands and contracts and any force from the beveled teeth that we have here on the gear pushing it one way or the other is held in place the shaft is held in place with this bracket here so this counter shaft at the top speed of the vehicle is only spinning at 7063 rpm which is well within the limitations of the bearings on this shaft here there's another bearing down in the the housing here that this is going to sit down into and drive our final drive here so that's two of the three main moving parts inside of this drive unit the next one that we need to look at is the shaft the counter drive gear that drives the counter driven gear here and that's the one that connects to the electric motor rotor so let's bring that in here next okay so this gear right here on the end of the electric motor rotor is what drives our counter driven gear but before we get into that let's just do a comparison of the front electric motor rotor to the rear electric motor rotor these are both induction motor or induction machines and these are both copper core they're very heavy this front one weighs 19.3 kilograms or 42.6 pounds the rear one weighs 27.58 kilograms or 60.8 pounds this rear induction rotor has 74 bars going between the shorting bars at the end here this one has 70 instead of the 74 so it's a little bit smaller diameter the front motor is 164 millimeters in diameter or 6.46 inches the rear motor is 194 millimeters

in diameter or 7.64 inches let's see what is that 30 millimeters larger diameter on the rear motor and then for length we have 131.6 millimeters or 5.18 inches compared to 154.8 millimeters so about a 23-millimeter length difference or 6.9 inches on the rear rotor here they both have maximum torque pretty close to the same rpm the rear motor has its maximum torque at 5630 rpm and the front motor has it at 5573 but keep in mind these have different size tires on them so at what vehicle speed are those peak torque rpms actually met okay let's take a look at the power ratings and some other things for these rotors here for the front induction motor, it's rated at 190 kilowatts or 259 horsepower and the same motor that's in the rear of the all-wheel-drive model s non-performance versions has the exact same specifications uh it will put out uh 331 newton meters of torque or 244 foot-pound-force of torque by comparison uh we have 370 kilowatts on the rear motor 190 kilowatts here so a little less than double the power on the rear motor versus the front for the torque we have 636 newton meters on the rear versus 331 on the front so a little less than double the torque so a very high-performance induction motor on the rear you might call it a low-performance induction motor on the front but it's not low performance at all it still has 190 kilowatts 259 horsepower and there's two of these you got one in the rear also so you still have 518 horsepower on an all-wheel drive model s that's not even the performance version and that's more horsepower and more combined torque 662-newton meters of torque than most performance cars have that's it's just incredible all right we talked about uh the gear or the gear ratios so this rotor here will have to spin 9.3441 times for every rotation of the tire on the vehicle the rear motor has to spin faster at 9.7344 rotations of the rotor to one revolution

of the tire and then the at the top speed 250 kilometers per hour 17 542 rpm on the front with the shorter tires 17 919 on the rear with the taller tires all right this rotor has a reluctor wheel here on the end for the speed sensor that sits in the case right next to the inverter it's right under the inverter cover and so we've got a speed sensor right here that's going to fit right over this and it's going to measure not only the rotational speed but the direction is it spinning forward or is it spinning backward here on the rotor itself this is a press on reluctor wheel and so I've pulled it off of there so before I set this rotor and shaft back into the case over here let's talk about the specialized bearings that are in this transmission as with the rear drive unit with the special skf bearings this rotor also has some specialized bearings and so does the countershaft and the final drive differential unit differential case there this bearing here on this end is a conductive deep groove ball bearing the explorer series SKF bearing but on the other side of the shaft we have an electrically insulated ceramic bearing and yes in my previous video I said that silicon nitride bearings weren't ceramic I was wrong I admit it I was wrong and thanks for the feedback and anytime I'm wrong I'm not afraid to admit when I'm wrong I do my best to try to make sure that I'm not wrong but I'm only human I messed things up too so anyway this is from what I can tell the exact same bearing that's on the rotor for the rear drive unit except it's not sealed it doesn't have its own lubrication put into it this actually has the lubrication from this drive unit sprayed on it constantly while the vehicle is moving and so this rotor unlike the front rotor this rotor spins in a wet environment it's not totally submerged but it is in a wet environment unlike the rear one that was in a totally dry environment this rotor is cooled by lubricant being sprayed on it the stator is cooled by the lubricant being sprayed on it and through it and so it's just a different design i don't think this one gets as hot as the rear one did because it doesn't have as much power we're not inducing as much current into this induction rotor as we can in the performance versions of that rear large motor so we have an insulating bearing on one side a conducting bearing on the other side and then we also have here on the end of the housing that the rotor fits in we have these little brushes right there you see those brushes yeah right there those are conductive little strands and it's actually called a shaft grounding ring with conductive filaments now I cannot see a brand name on this and I apologize to the manufacturer of this part, if I say that somebody else did it and in fact it was you but I searched the internet and the only one I could find that looked anything like this is made by a company called AEGIS, AEGIS and they make a whole bunch of different grounding rings and this particular one right here that I've highlighted in yellow looks just like this one here but it doesn't have a brand name on it and a shaft grounding ring is there to do exactly what it sounds like it's going to ground that shaft electrically ground it so these all these little brushes here are in constant contact with this rotor here so that saves the bearings if we had two conductive bearings then that would give us a complete path through the shaft through the housing back through the shaft and we would get arcing and pitting of the bearings and they would destroy themselves over time and so the shaft grounding rings are there to make sure that it does not do that so let's take this rotor now and put it in the drive unit housing over here we've got our rotor our induction rotor here that is going to spin with its 31 teeth and drive the 77 teeth of the counter driven gear that will give us a gear ratio between the electric motor and the counter driven gear of 2.4838 to 1. and then its 21 teeth will drive the 79 teeth of the ring gear and give us a gear reduction of 3.7619 to 1. so if we take both of those gear ratios and multiply them together the 2.48381 from the rotor to the counter driven gear from the counter driven gear to the ring gear of 3.7619 we end up with an overall gear ratio of 9.3441 to one so we have to rotate this rotor 9.3441 rotations before we get one rotation of your tire here and so here on our differential

case we have our side gears and our differential pinions on one side of the front-drive unit from the bottom side we have a CV half shaft that goes out to let's see that would be the driver's side so that would be the left front tire the right front tire on this model has an additional shaft here called the jackshaft that slides into the side gear and extends out as a certain dimension I haven't measured it but what that allows us to have is equal-length CV half shafts on the front of this car and that will help reduce torque steer under heavy acceleration so that's the purpose of this jackshaft right here okay so in the first part of the video we've just talked about the gears but then we've also talked about how fast this rotor and these bearings have to rotate and so we've talked about the special SKF bearings a special design for these tesla motors and if you go to the SKF website you can download a catalog they also have an app for their bearings where you can look up the specs on them and you can see some data in the screenshots here showing the maximum RPM recommended for these bearings without doing something special, well tesla does something special with these bearings to make sure that they can withstand higher RPMs than their mechanical speed limit okay let's talk about the lubrication system on this front-drive unit this unit sits in the front of the vehicle kind of on a tilt very much like this to where this flat spot right up here where there's a heat exchanger to cool the transmission fluid would sit pretty much level maybe just slightly tilted we have a gear-driven oil pump right here some sort of a nylon plastic-type gear that is going to be driven right off the teeth of that 213 millimeter ring gear that your axle cv half shafts connect to and move the vehicle down the road the pump has an inlet arrow right here and it comes over to a fluid screen, I took this out and took it apart it just has a little metal screen inside of it and so think of this as the bottom area of the transmission where the fluid is going to be accumulating and on the other side here there is a fluid drain plug that would be down towards the bottom of the housing with it installed in the vehicle and then there's a fluid fill plug right up here now one thing I read in the instructions on changing this fluid is that unlike differentials and some other transmissions and drive units and so on you don't keep adding fluid through the fill plug until it starts coming out because that will overfill this unit so here's the fill plug right here and this is approximately the angle it's sitting in the vehicle if we filled it up with fluid right there the everything would be submerged in oil which we don't want and so it gives us an exact specification for the amount of fluid going into the front-drive unit and it has a warning here it says use exactly the specified amount of fluid do not fill to the top of the fill plug and so the fluid that goes in here and yes in my previous video, I embarrassed myself by saying it was not Dexron VI transmission fluid in this drive unit prior to a certain drive unit part number uh it is not Dexron VI. it's a Mobile SHC 629 which I've looked up if you look at that up on the internet it's a special uh high-quality PAO based synthetic gear lube and it's intended for applications where the fluid wouldn't be changed very often and could last a very long time well that was for drive units with the part number of 1035000-00-F and earlier and so if we look at this drive unit part number right here on this 2016, it is the F unit and so that's one of the reasons I initially said these didn't have decks run in them because the fluid that came out of this was orange and Dexron is red and it was a strange kind of an orange color and I wasn't sure exactly what it was but if you have a model j or higher then it says to use Dexron VI automatic transmission fluid and since the fluid that it's replacing is a high quality PAO based synthetic fluid you don't want to go buy the cheapest universal Dexron fluid you can find this has to be licensed Dexron VI automatic transmission fluid and if you don't think it makes a difference I've got some videos on transmission fluid differences and specifications that you really need to look at and then see what you think so yeah it uses Dexron VI on probably I would say the let's see this is 2016. it's got to be somewhere in the 2017 maybe and above range that they went to Dexron VI but anyway it can be the previous previous fluid so if we follow the output of this pump here, it pumps fluid up and it's going to go to five different things and so the first place that it goes is through this little tube right here as you can see in the photo and that's going to spray lubricant over here on this rotor's bearing and gear so the drive gear with the 31 teeth and that bearing down there that has to support this rotor spinning at 17,542 RPM at the maximum vehicle speed that bearing needs constant lubrication to be able to withstand the higher speeds that it might rotate at because at the higher speeds the bearing gets hot the ball bearings themselves expand and these are special expanded clearance or in larger clearance bearings made to expand just a little bit it's in it's in micrometers that it expands but it does expand um and so it allows for uh that expansion to take place so that's one of the five places it goes the second place is it comes up through this hole right here and goes into a transmission oil cooler a heat exchanger and so we have coolant coming in one of these ports here i don't know which one it is i couldn't figure it out so it's in one and out the other but there's coolant on these two holes and transmission fluid that comes in on this one and out on this one and there are four holes in the bottom of this transmission heat exchanger that looks very much like the heat exchanger portion of a chiller that is used to cool the coolant that is running through this so on the front of the Model S there's a chiller that looks just like this hanging down in the front it's probably 20 millimeters taller and has air conditioning refrigerant running through it to remove the heat from the coolant that goes through it and so this is a heat exchanger to get the heat from the transmission fluid into the uh coolant and then there's another heat exchanger to transfer the heat from the coolant into the refrigerant and then that goes up to the two condensers in the front of the car and is radiated out and blown out with convection heat transfer into the air and some might argue on cold days if we're heating the battery that we could also run heat through the heat exchanger here to help warm up these gearboxes I don't know if that actually happens I still need to investigate that further all right so there's two places we we feed lubricant to this bearing and gear on the rotor bearing that needs lots of lubrication but the other one needs lubrication too so the fluid comes through the heat exchanger and goes down and out this hole right here there's a hole right here where this housing that has the conductive filaments in it to ground the rotor has this long tube right here that's going to fit into that hole so it's going to be like this and if you look at this tube here it has a whole bunch of little holes in it can you see those holes let's see that is called a sparge pipe according to some feedback I received from users in my or viewers in my previous video a sparge pipe. it's going to going to spray cooled transmission fluid down on top of the stator assembly and then it has its own drip channels right here to run down onto the windings on the end of the stator assembly so this is the third place that transmission fluid goes and this is after it's been cooled it's cooled down so we're using the cooler transmission fluid to try to cool the stator that gets really hot and then inside of this housing this pipe makes kind of a u-turn and comes back right here and sprays as you can see in this photo uh on this rear bearing over here on the stator the silicon nitride non-conductive bearing is what it's spraying its oil on okay and then the last thing that that fluid feeds I take that back there are two more things that the fluid feeds so there are six places that that fluid goes we have a drip channel right here as you can see in this photograph there's little holes in the bottom of this where it drips transmission fluid down onto the front windings of our stator assembly and then we have an inner spray nozzle right here that sprays on the rotor itself so a complex lubrication system it's especially important for these two bearings on this rotor that has to spin clear up to the 17,542 RPM those bearings have got to be kept cool and well lubricated so make sure you've got the right good quality transmission fluid and then make sure that you fill it only with the prescribed amount of fluid which I never gave you for the transmission front small drive unit it takes 1750 milliliters or 1.8 quarts for the small unit in the rear it takes 2250 milliliters or 2.4 quarts now you might be thinking why does the rear small unit take more than the front small unit the rear small unit has a remote mounted heat exchanger, it's not bolted right to the drive unit itself I don't think there's room so they put it off to the side there and then for the rear drive unit the great big performance one it's 1400 milliliters or 1.5 quarts of fluid so we've talked about the gears we've talked about

the rotor we've talked about the lubrication we've talked about the bearings the last things we need to look at are the electronics involved here the electrical components okay this is the stator assembly for this front motor and I assume for the rear small motor as well this is a three-phase four-pole stator it has 48 slots inside of it and if you remember the rotor itself has 70 bars and so this is an induction motor we're going to run three-phase current through these three windings here three sets of windings here and induce current into the rotor which produces its own electromagnetic field that is attracted to and repelled by the magnetic field in the stator here which makes it rotate and they can change the speed of the motor by changing the frequency of the signal applied to it they can change the torque that the motor produces by changing the amount of current going through it in relation to the timing of where the rotor is within the stator itself this stator assembly weighs 23.7 kilograms or 52.25 pounds it's very heavy the windings themselves the three-phase windings I took my Hioki milli-ohm meter and measured the resistance of these three windings and I measured 13.7 approximately milli-ohms of resistance so that's 13.7 thousandths of one ohm

per winding, I had 13.7 on one 13.68 13.52 all in this 13.5 to 13.7 milliohm range now by comparison the milliohm resistance of the rear drive unit the performance rear-drive unit they're only 5.5 milliohms so almost three times less so very low resistance very high currents to induce high amounts of current into the induction rotor to give us a lot of torque a lot of power one thing that I'm picking up about induction motors because I am certainly no expert on them is that you can make these motors be very high performance by just running more current through the stator increasing the voltage running more current through it and inducing more current into the rotor assembly but then you've got a problem of everything gets hot you got to keep it cool and so on so the induction motors seem to be the performance type motors that are out there but as you've probably seen in other videos in red they're not quite as efficient as the permanent magnet synchronous reluctance motors or just plain permanent magnet motors that have been out there for quite a long time, I think the reason that we still have an induction motor either in the rear or the front of these teslas is there because it is a performance motor and the internal permanent magnet synchronous reluctance motors that are either in the front on the tesla model s or the rear on the Tesla Model 3 and why those are the efficient ones and I'm curious, I don't know I'm still trying to find out as you drive down the road does it use both front and rear motors equally or let's say if you are just cruising at a freeway speed and you have a permanent magnet style motor does it run on that alone or mostly on that to increase the battery range that they're getting here that's what I suspect I haven't been able to prove it yet but I'm working on that so I think they're giving us the best of both worlds we have the induction motors for the super high performance combined with really good performance from the permanent magnet ones but the permanent magnet ones give us a little better battery range because of their efficiency and so anyway just some thoughts I have no proof on it but as soon as I uh can I'm going to try to get data from our Model S as we drive to see what is the split between the front and the rear and if any of you know that information if you've experimented on your own car you've got scan tool access or other means of grabbing those PIDs those data's off the can line there let me know when you're cruising is it mostly the permanent magnet motor that's propelling you or is it both I'm very curious to find out okay so this stator assembly these three-phase cables right here are powered by the inverter assembly right here and some of you may recognize this from the video that I did on all the high power high voltage electronics uh on the vehicle and what I should have said is the high power connections between all the high voltage components but this is the inverter and the inverter has our dc power coming in from the battery right here we have a negative and positive terminal connection right there and then we have our three-phase ac current going out right there power applied to these three phases three-phase cables right here on the stator assembly and so that's the connection between the inverter assembly and the stator the inverter is in control of the current and the voltage and the frequency at the stator itself now this inverter assembly is liquid-cooled as you can see here we have a coolant fitting right there and another coolant fitting right there one is the inlet one is the outlet there's a heat sink in here there's a vent right there we have our low voltage electrical connection right here our data connection our logic connection right there that are inputs we've got serial data can data there'll be other inputs such as throttle position and and rear motor speed and brake pedal position and other pieces of data that are needed to control the front motor I'm curious if somebody put the same size tire all the way around on a vehicle that was intended for different size tires I suspect it will work just fine but somehow it's got a learn that pick that up have any of you done that, have you taken off the two different size tires and just put on the single size tires and what effect did it have if any oh one other thing the stator has a temperature sensor and as you can see from these two broken wires right here as i was removing the stator from the housing that it bolts to right here i accidentally yank on these wires and broke them so there's you can see a little tiny piece of the wire sticking out right there but there's a temperature sensor inside the stator looks like just a single one with the two wires here monitoring the temperature of the stator windings themselves all those drip channels that we looked at the drip oil down onto the stator that's on to these windings of copper wire right here and then the stator frame right here is where all the holes in this pipe right here would be dripping fluid down onto that and cooling it also one last thing the stator as you can see is open and exposed unlike the stator on the uh rear drive unit from the previous video and that stator actually sits inside of a big housing so this housing right here goes over the stator and it sits right here on the transmission case and so if I lift that off the first time I lifted this off I saw this stator right here there's two locating pins or two alignment pins right there that line up with a hole right here and a hole on the other side and so this stator fits right down in and lines up with those pins and then this cap right here fits right here on top of the stator assembly and then this housing fits over the top of that and so this housing had oil in it and it's a complete kind of oil bath it's not submerged but there's certainly transmission fluid that's in there for cooling and lubrication here on this model and as I said I'm almost positive from what I've seen in pictures of used rear drive units of the small motor design but it's the same thing on the rear I could be wrong if any of you know exactly what the rear motor is internally I mean does it look just like this is it is it the same it's just in a different housing i'd be curious to know if that's the case I'm still looking for a front electric motor for the 2019 and above Tesla Model S to see if it really is the same as the rear motor on the Tesla Model 3 from what I can tell it is but I guess we'll see obviously if any of you know if I'm wrong or not let me know in the comments as well okay well we've looked at a lot of things here on this tesla model s front motor I know it's a long video but there's a lot a lot to it it's very interesting to look at and explore and I really enjoy that if you feel that you've benefited from these videos that I produce please consider a donation to the Weber State Automotive Technology Department there is a donation link at the bottom of the video description for those of you who have donated thank you very much for your donations I greatly appreciate those and we are going to put that money to great use here you'll be able to see additional videos and comp of components that we would not be able to afford uh without that and I greatly appreciate that so once again from weber state university thanks for watching have a good day

2021-04-01