3D Scanning and Printing - Class 5

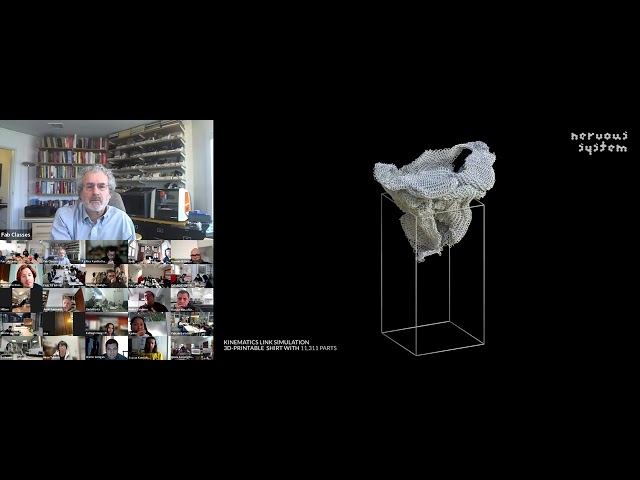

thank you so today's class is 3D scanning and printing we're going to alternate for a few weeks next week back to electronics week after that back into Machining and uh Adrian points out I'm not sharing this screen now I'm sharing the screen okay so this week we're going to scan and print then we're going to alternate uh next week you'll design Electronics then you're going to do large format Machining uh week after that you're going to do um uh produce Electronics you might have thought this was a class in 3D printing the whole Fab Academy this week is about the strength but also the weakness of 3D printing uh 3D printing is powerful it's important but it's only one of multiple fabrication processes and so you'll be meeting things that can make things uh bigger or stronger or faster than 3D printing within that range 3D printing has a very important role in complexity of geometry so this isn't just about how great 3D printing it is it's about understanding how 3D printing relates to all the other processes we'll learn about so subtractive Machining dates back to 1952 at MIT with the tool that cuts there are many different claims to inventing 3D printing this is one of them for stereol lithography there's maybe five other claims to inventing 3D printing they all have to do with computer controlled deposition so why this is a 3D printing hobbyist in Switzerland who's done beautiful work making things like this is an all 3D printed clock so one of the main strengths of 3D printing is just the geometrical complexity of what you can produce uh this is a nice project that's 3D printing flexors things that deform to make microscopes um this comes out of the Kerala lab this is an all 3D printed uh milling machine so you're going to make little circuit boards this is 3D printing the machine to make the circuit boards so what's good about all of those examples is complexity in a sense is free it takes about the same time to make a complex geometry as a simple geometry so it opens up design space a second one is because you're printing you have access to the internals so if you want to make like a nested part like an axle that fits through a sleeve done conventionally you need to make them separately and fit them together with 3D printing you can actually print the nested part right inside the thing around it and third is it's roughly net shape meaning there's depending on how you print there can be some typically some waste material but you're not removing a lot of waste material you're roughly putting material where you want it and so you reduce uh waste um oh yeah Roman is noting um I should add yeah yeah in the chat there's an important comment comment from Roman and um see let me get to the right place um I'll add a little more on the history um uh it's the let me copy this copy um there's a uh French uh inventor Ramon I didn't realize there was a recent fight over that that's been a long-standing one there was a recent uh decision no I don't think so but I I I I I got the opportunity to discuss and he mentioned a few weeks but uh you know uh okay but yeah Jean-Claude um uh I probably had maybe has the best claim to being the first to register um Ramon I'll update this page to add a few of the different um there's there's a very strong nationalistic different parts of the world claim that they invented 3D printing yes I was I wasn't mentioning it as a joke but it's true but it does but I I should add a little bit more on that because um yeah and Jean-Claude has a strong argument connection good okay so those are all good reasons for 3D printing uh um now let's see this is a classic benchy is a classic 3D printing test problem uh there are many limitations in 3D printing a 3D printer is not like a 2d printer where you just push print so a big limitation is you're going to see all of these uh the most common technique you'll use extrudes a filament and if things go wrong you get spaghetti um uh some of you might be using a technique where you fuse powder and things go wrong you get earthquakes some of you might be using a technique where you expose a resin and if things go wrong you get goo uh there are a number a number of failure mechanisms just within the printers uh second the feature size is limited by the printing process and for things like the resolution of the surface finish can be much lower than you can get with other tools we'll use um uh time is a big one uh let's see this is a link to a let's see an ad but after the ad is is erased to see how fast you can print Banshee but on a typical printer for a typical project it takes um uh hours see the Ricardo is adding this link oh I see yeah that that is a good uh summary uh typically for a typical printer for a typical design it's ours there's research on bringing that down but it it takes hours and it's not unheard of to have a job that takes uh days uh on the materials open printers where you can use any materials the cost of come way down but commercial printers with commercial materials are very expensive you can spend hundreds of dollars on a small print so uh for the materials this is uh these are two different tables of materials you can print uh that are convenient and I'll talk about printing processes and printing vendors about the trade-offs among them there are a number of polymers and I'd say uh out of all of them uh polylactic acid pla is the most common but they're polymers that are harder they're polymers that are flexible they're polymers that are translucent polymers that are solver uh soluble those are most common um there are fillers uh I'll talk about printing processes you can't directly print wood and uh uh outside of um a high end it's much harder to print metal but you can use fillers of these in other materials um so uh Jason is asking about carbon so again there there's a lot of claims and counter claims about the carbon process there's a lot of research projects working on speeding up printing that's very much a work in progress uh something to know is not all but most of these materials are hygroscopic which means they absorb moisture which means how you store them matters so you want to store them sealed when you open them over time the qualities of the material will degrade and I'll talk about that more in a little bit um uh let's see I'll talk about post-processing uh in a little bit so this is a very important article when you print the printing process releases volatile chemicals and it releases uh micro particles and so this is a really nice article and there's two important tables here uh this is the fine particle emission um this is a logarithmic scale so each is a factor of 10. this is polylactic acid this is a range of other materials and then this is ABS and what you'll see is there's a huge difference between the particulates between PLA and abs and then this table down here uh is emission rates for volatile uh Organics and again this is PLA and then this is ABS and other materials and what you should take away from this is uh pla is office friendly you can sit next to it in an open printer and it's not particularly hazardous but just about anything beyond that needs ventilation uh you you'd like to have an enclosed printer with a uh HEPA is a type of filter that filters the exhaust from it ideally you'd like to vent it outside if you can but you need to be aware of that so behind me I have a sealed printer um with an environmental filter that I use in my office in my basement I have printers that are open where I print with other materials um where I don't want to be breathing what comes from it so you need to be aware of the printer as a environmental Source uh and that's one reason why uh I would segregate pla printing from other kinds of printing next is a key thing is the design rules so you can't send anything to a printer uh these are images of a series of tests you'll find many different test parts this is just a series of test Parts I did a few years ago one test is you need to support the print so probably the best example ever of this is this was a beautiful project from a group uh nervous systems and they they wanted to print clothing and so what they're doing here is mathematically they're lowering this into the print volume and then after doing that mathematically they send that to the printer and print it but now to print it um uh you need to support the um all of those links so in this case this was designed around a print process I'll describe which is a powder bed and so the powder bed supports all the links but for any other printing process you need to separately remove the support which can be very annoying um Jason is asking about vending um Jason this is similar to uh it's not as bad as laser cutter venting but it's but it's in the same Spirit as laser cutting venting again it's not there aren't it quite as much volatile but you don't want to vent it where people breathe at so in research Labs you vent it to the roof with a high velocity fan shooting it up um short of that you want the vent away from where people can be breathing the exhaust so for the supports um it's a yep um remind you're noting uh PHA that's biodegradable um yeah and Pla is also a plant-based okay so coming back to the design rules uh in each of these I've got a free CAD file I've got an STL I'll talk about formats and I've got a picture so uh one test is overhang so here I've got something sticking out and then I need a support to hold it up and so for fdm which we'll talk about in a moment um uh uh you you print uh a block in here that that is designed to not quite adhere and then you pull that out so that's the test for overhangs um then an important test is clearance what I've done here is I've printed a series of rings and I'm going down in steps by a thousandth of an inch and all of these released but but those they got so close that the two parts bound to each other and I couldn't release them so that's measuring how close a wall can be before it sticks um to get a part that moves then uh ideally uh other than something like a powder bed you want to print without supports supports take more time to print they create waste and depending on the process they can be difficult uh when you learn about the design rules you can learn to print uh surprisingly most of what you need to do without supports so this is the most important one what I've done is I I'm changing the angle and so this is just vertical it's perfectly fine uh this one I'm coming out horizontally without a support and I get spaghetti underneath it because there's nothing to hold that up but this is in degrees you'll see around 20 degrees or 30 degrees that's enough so each layer Builds on the layer below it so as long as you don't have flat surfaces but just slightly angled surfaces you can grow out without supports so that's maybe the most important of the design rules um this one is testing how far out I can go horizontally so a short distance I can go without supports the further I go the worse it gets if I try to make that unsupported but that's immediately followed by this which is bridging if you look at here I'm going a long distance without support and the reason for that is uh in what I'm doing um uh uh um if I'm building up a layer here and I'm building up a layer here um if I then start going off into space if I stop I lose I get a mess but if I can come over to here I'm pulling the filament from here to here and then I anchor it here so that's called bridging bridging is where you pull between two places you've built up and so for example if you have a house and you want to make a door the the roof here can be flat rather than my comment about needing an angle because here you're bridging over the door so as long as you're pulling between two anchors you can span quite a long distance without needing a support so that's bridging next is wall thickness so here what I'm doing is this is with I'll talk about processes a stereol lithography printer I'm making the wall thinner and thinner and depending on the process there's a limit to how thin the wall can be before it fails and on the opposite side I'm making the Gap thinner and thinner until it gets so close that it closes up so there's a limit to the thickness of a wall um this is a test where I just made a volume and I've set the outside Dimension and the inside Dimension and depending on the print process the actual size you get can be a few thousandths of an inch off of what you think you got so when you're designing parts that fit together you need to characterize the dimensions you get from the printer versus what you think in theory there's no equivalent to kerf in theory the dimensions are what you tell the printer in practice depending on the printing process there can be some deviation between what you get from what you ask for uh most printing processes are anisotropic so in this process the layers are horizontal and so uh the the bottom piece here is strong if I pull it in tension because I'm pulling on the the fiber layer here if you look vertically if I pull this intention um it's much more prone to delaminate between the layers so the um uh strength of the print depends on the angle of the print um this is just printing a sphere and you can see on the side it looks nice and smooth on the top here you can see the steps because there's a flat angle compared to how I'm layering it I'll talk about some ways to deal with that then infill is you can print a dense structure that's strongest but use the most material and takes the most time here I'm printing a completely Hollow structure that prints fastest and is weakest and in between you can vary the density of the infill which is around the parts you don't care about uh um how much you fill them in and so that's trading off material use and printing time versus uh strength of the part uh then a final one is uh if you have a sharp corner when you print that what you'll actually get is sort of a mess there and the problem is because you can only fit one layer of filament at the sharp corner then two and so you don't want to do that you want to facet um so that the printing can create a few solid layers uh to give you uh a sharp edge you don't want to have a sharp corner so all of those are design rules and you want to design your design around the constraints of the printer to make a strong part with a good finish that prints quickly you don't design an arbitrary part and hope the printer can do it you want to learn your printer's design rules and so the group assignment is to test the design rules so I want to check how thin can a wall be before it collapses how close can Surface be before they touch what's the dimension of the part you actually got versus the dimension you asked for um so run run you can run these you'll find a number of different uh test parts for it uh next is uh the most common printing process you'll be using and I'll talk about others extrudes a filament and the distance over the bed is critical um if the head is too high it's printing in space and it doesn't stick if the head is too low it actually digs into the bed so you want it to get that Dimension just right and further the bed might not be exactly flat so so the right distance depends on where you are so when you get close to it if you print Too Close inside view the the what you print is squashed very thin if you're too far away it's not even really sticking and there's a happy place where when you print it's it's just sort of slightly squashed to be the right distance um let's see I'll talk about non-flat printing uh shortly Luke's adding this which is um uh printing with arcs to try to avoid um overhangs uh that's related to non-flat premium which I'll talk about shortly uh so uh setting the height of the printer over the bed is a critical parameter when you set up a printer you need to adjust that and you need to get this happy place between squashing the print and not adhering and uh better printers measure that each print um uh cheaper printers you set it and hope it stays right but it drifts over time uh better printers each print job they characterize the print height and uh adjust it now one of the other annoying things is and one of the reasons for the failures I showed you um let's see I'll talk about textiles shortly uh you start printing and if the adhesion here isn't very good part way through the print process it starts to come off and you get spaghetti so um how the print sticks to the bed is another critical parameter one approach is to put glue on the bed like a glue stick I don't recommend that because that builds up and gets gooey and sticky um you want to keep the bed clean is one thing uh from things like oils on it and then something you can there's two things you can do one is you can print um a raft which is a layer designed to help adhere to the bed and then you can print a brim which is a lip that helps hold the part down so you'll have to experiment with your printer in your process but um typically cleaning the bed and adding rafts and brims will help Parts uh that as the part cool it cools it can bow a little bit and that's part of um what causes it to come off the bed once you're done there's a lot of things you can do to post process so this is a resin uh like I believe this is epoxy base excuse me and so when the print comes off typically you can see layers from the printing process depending on the print um this is a filler that you smooth over it that will give you a much smoother finish there's a number of different materials you can use to do that and then a really powerful technique is uh plating and in particular you can electroplate which is uh the print in a polymer you can coat um and then put it in a bath where you drive a conductor on it so rather than printing a solid metal part you can make what look like metal parts and have conducting surfaces by electroplating and this isn't that difficult to do the chemistry is not very bad for electroplating so we get to printing processes this is a good table shapeways is one vendor that maintains every kind of printer and uh so in their list they list examples of output from lots of different types of printing processes um oh sorry yeah um Ricardo mentioned about annealing the um let's see um the uh for the fdm style printing you're printing into um with the material just above the bed it into a temperature just below it um better fdm printers have a heated volume that takes care of the annealing of the part um generally annealing is less relevant for fdm printing it's essential for uh things like the um uh powder printing I'll be talking about shortly so so yeah let me fill in as I talk about these so stereolithography is one of the first processes uh 3D Systems was a developer of that uh in that you have um a bed of a resin and then you have uh typically a laser use scan and where the late you spread a layer of resin and where the layer hits it you fuse it so stereolithography uh is the I'd say the highest resolution of the printing processes uh because you're printing down to the resolution of the focus of the laser that that can be Micron resolution originally they scanned lasers uh faster ones use um uh digital laser micro mirrors to do parallel exposure that um uh it typically isn't quite as high resolution can print quicker so STL is has a limited range of materials but is great for high resolution uh uh fuse deposition molding was developed by stratasys uh fdm refers to uh that process fuse deposition molding um there's a few other terms that get used because they consider that their term like FFF for this in these what you're doing is you have a uh nozzle and the filament goes into the nozzle it's just above its melting temperature and then it comes out and there's a heated bed that's just below the melted temperature and ideally you're also in a sealed chamber that's just below the melting temperature and so it comes out but it sticks and it stays where you put it and so uh these have extruders this is an article on a smaller extruder uh lets you print more uh High finer features a bigger Cruise extruder lets you print more quickly and there's been a lot of work on optimizing using a bigger extruder but controlling how you use it to get the best of both of those uh in the family of these generally you're extruding polymers but you can extrude other materials these are colleagues at Berkeley um that have printers that extrude Clays to make these sort of beautiful objects uh by extruding Clay um uh this is a colleague at USC that excludes concrete to make uh buildings uh on on really big scales so fdm is the most common process it's likely what you're going to use uh it's not the highest resolution it's not the fastest um but it's low cost it's flexible and it has good structural properties uh this is an emerging process where uh and this has various names in this what you do is instead of extruding uh plastic uh you have for example a little plasma torch and you extrude a metal through it and so it's like fdm Printing and plastic but you use it to write with metal and so that's one of the metal printing processes um uh uh so yeah just so you can get set up in a Fab Lab to do electroplating uh and again formlabs has a good uh the link I showed before is about getting set up to do it electroplating isn't kitchen chemistry but it's not hazardous chemistry in a hood formlabs has a good page on getting you started with electroplating uh inkjet binders this is a link to uh 3D Systems bot Z Corp one MIT spin-off here what you do is um uh and actually HP has a related one uh you spread a layer of powder and then you print an ink that binds it together that's great because the um these powder bed printers are the winner for support because you spread a layer of powder and then you selectively Center it together then you spread another layer and you selectively Center and the unsintered powder supports the rest and so they automatically make the supports and you just take out your part now the inkjet approach is um uh let's see uh frictions let's see I didn't friction store welding is an important welding technique I'd never heard of friction stir additive oh that's interesting so so you take a a bar of material and turn it really fast and yeah use it to build up a part yeah frictionster welding is a crazy sounding thing where um uh if you want to join two materials together um you just bring in a head spinning really really fast and you smush them together it seems like a really crude idea but it it's among the best strongest welded joints uh but I had never heard of it being used to deposit material as an additive process that's interesting uh that sounds very promising uh so the inkjet approaches uh what's good about them is there's no supports and what's also good is you can print in color with them what's bad is uh that they're weakly fused so these need post-processing these need annealing um or infusing you need to do something to strengthen the joints um polyjet is one of the nicest uh processes um uh this is from stratasys and what this one does is it inkjet prints little droplets of material and then uh fuses them when when um uh optically and so this process and I'll show examples shortly uh is very high resolution and then it handles multiple materials which can vary structural Properties or color uh the limitation in this is uh it's very expensive the machines can cost hundreds of thousands of dollars but this is among the highest resolution and highest performance um uh this was an interesting side corner this is a printing process where you uh um I guess this one is obsolete now uh but you would print sheets of paper cut them out and glue them together they looked great they had terrible structural properties uh looks like they're no longer in business so I'll drop that then laser sintering is where you spread layers of powder but rather than printing you use a laser to fuse it together and so this is used in the highest end metal printers and these cost a million dollars but it's also becoming accessible in uh uh laser Fusion uh printers that are not millions and not thousands but tens of thousands that I'll talk about uh two Photon printing is where instead of using one Photon uh the link looks broken I'll fix their link yeah these happen when people update their sites but um Nano scribe um I want to show you images of their printing what they do is near nearly Nano printing so by using two Photon printing uh there's a resolution enhancement at the focus of the laser and so this lets you make prints with features that are uh microns uh millionths of a meter uh and then this last link is and there's been a lot of work since then but this was a meeting I ran looking at not printing but assembling and disassembling and so research on uh micro assemblers rather than printers and this is promising to make high performance a functional uh systems so let's look at the machines now reprap was started by a dear colleague Adrian Boyer and Adrian's interest wasn't really 3D printing for the masses um what he wanted to do is um let's see uh what he wanted to do was make a printer that can print a printer so this is an article on self-replication and Adrian famously I think that there's a picture in here of um uh had a printer then print the parts of yeah you know this doesn't show the picture I'm looking for but um had had a printer print the parts of the next printer and so he was very interested in how a printer could make as many of its own Parts um Charlotte yeah so um for bioprinting it's not done typically with inkjet it's done with syringes I'll add a link to in my lab's done a lot of work on this there there's bioprinters where you have syringes that put out gels that are medium cells grow in and extrude gels so typically those are the syringe type printers so reprap started an open design for a printer aiming at printers that could print a printer and many projects spun off from that so ultimaker uh started at Fab Lab in Utrecht in the Netherlands and they did a lot of work to optimize uh the print speed to reduce the moving Mass to get it printing as quickly as possible they did a a heroic wonderful project to make a full-size elephant and they did it by mounting printers on gantries so that as the printer prints the printer itself lifts away and then they made a whole line of these printers and printed a full-size elephant I think it took about a month to do um but printed an elephant um prusa then has done a really good job of taking the lineage of tracing back to the reprap um refining the design and occupying a really nice sweet spot the prusa is an open design you can download everything but you can buy it from them in kit form at a reasonable price or you can buy it from them in a finished form and so they've done a really good job of that and so that's a classic fdm printer it's very easy to configure it's very easy to optimize uh it's very reproducible reliable these are those test Parts on a prusa printer uh sane spark are uh Shenzhen colleagues and they've taken that lineage and um they've done a good job of just dramatically um cost reducing and so they've brought uh printing costs down to hundreds of dollars with nicely optimized printers the earliest ones didn't measure Z position and as a result uh we're fairly unreliable they've now uh tuned that in uh and uh one of the things they make that's really interesting for the labs is they make moving bed printers um uh let's see I'm adding a link uh they make this moving bed printer and so the original reason for that was you can keep the printing running overnight and the parts just fall off at the end but one of the uses we found for this is you can have a take up roller and you can just keep the printer running and you can print long extrusions so if you want to make a machine you can print machine parts bigger than the machine um Hank is also noting uh voron which is aiming to take this lineage and optimize it um Hank what have you decided about this after working on building yours it's almost ready okay so I did that time after boot camp so with uh soccer is now making a sort of lost box okay and I hope we will be working uh in the next couple of days okay I'll be interested in the report it's been a long time also I added a link about the the one meter axis we might as a boot camp oh that's great so this was he mounted this vertically and then just um uh started Printing and printed out this long axis uh from the moving bed yeah uh this was a great example of bugs that are features Hank didn't have a place to put the printer so we decided to stick it on the wall and it had the benefit that it it comes out it bows a little bit as it comes out um but he's able to print this um how long was the axis uh one meter yeah so be able to print a complete meter uh axis nice um uh cindo is an interesting company they they make uh 2D printers and they took uh 3D printers and productized it and so um uh let's see Jason is asking about Naomi I don't know the history I'd be interested if you know more about the history um uh that the same smart what's nice about these is they're completely sealed and these are not designed for tweaking but they're much more user friendly in that you just push in a cartridge you push print and it pretty much adjusts anything um uh this is an emerging multi-material printer to add multi-material printing to other printers then form Labs is a company that was spun off from my labs uh one of my students Max and form Labs their goal was to improve resolution for everyone to bring down the cost of high resolution printing so um their main product is this which is a stereo lithography printer and uh this is what the test Parts look like on that and so if you compare this to what I was showing you before what you'll see is the feature size is much finer and the surface finish is much better uh than fdm printing um this is uh um a documentary about a famous fight they had with 3D Systems about the emergence of it uh that's Max and David inventing it and they've done a number of interesting projects with it this is one I love this is a 3D printed stop-motion movie oops let's see it didn't like it when I made that full screen a 3D printed stop-motion movie and every frame of the movie is a print so they printed these huge numbers of parts [Music] and every frame of the movie is is a print ing give me days so really beautiful project with it um and then one of their most recent projects is they're Mass producing characters so with Hasbro you can buy a superhero that's you and that's done by having a big print Farm Mass producing individual characters and then more recently they've come out with a laser center system and this is uh uh thirty thousand twenty thirty thousand dollar range not a million dollars this doesn't do metal uh it does typically nylon but the nylon can be glass or carbon fiber reinforced so it makes dense Parts with good structural properties pretty good but not fabulous surface finish a little bit rough from the powder and the real attraction of this is aside from the good structural properties is because of the powder bed they can be essentially arbitrarily complex you can make tremendously complex parts and you just sort of reach into the bed pull it off shake off the powder and then um blow it off and blast it off and so this is more than an entry-level printer but like in the super Labs we're adding these for uh Laser Center then uh stratasys uh has this machine oh that's another broken link um uh so the j55 uh is one of my favorite printers uh this now costs a hundred thousand dollars but in return you get this um so uh it prints with jets of material the Jets can have different colors and so this is 3D scanning issue and printing a shoe this is printing this with uh the channels for the microfluidics and all of these aren't color on the surface they're actually volumetric color and so it really does gorgeous color printing um uh Ohad are you on the call I am yeah can you talk about your role with strategists and just your thoughts about 3D printings so now I'm in charge of innovation and sustainability at the company um so I I believe in multi-material printing and this is what uh this allows to do uh recently we have the ability to print air as well and print on fabric and other things so it's kind of a disrupting the um different Industries um but I think that the 3D printing it still didn't reach to the point that we can use it uh daily although we can see that in many Industries and most materials and multi-processors maybe can take it to them currently the highest performing process right now it's a hundred thousand dollar scale uh this hasn't yet been turned into DIY consumer machines that'll come in the coming years but but we're still a few years away from DIY versions of this but we're putting this into the bigger kind of super labs mm-hmm good and yeah for a full stop motion Movie by Leica that is fully 3D printed oh another um and also Kobo they did the the movie cover was uh like all figurines were 3D printed cool okay I'll add links to these beautiful um yeah and any questions ohad's a great resource on 3D printing uh then uh in the uh this this is a site associated with the machine building class I teach uh there have been a number of printers done in that uh uh Danielle and Gracia uh Fab instructor Guru uh is developing versions of printers uh this is a really neat version of a printer where instead of having a thick scan tree you put it in a room and uh suspend it um uh the um all of these are Open Designs an interesting part of parameter spaces um yeah a carbon uh uh Harney is asking about carbon my list here is an exhaustive each of these is a different part of parameter space the you know compared to carbon I like the stratasys polyjet process because it does a really good job of multiple material properties um for these sort of higher end printers uh precious plastic is the opposite this is a really nice project with Open Designs and um let's see and what they have is a series a team what um I want to see the machines sorry the their sights uh here sorry this is the link I want so they have a series of open designs of machines and um uh um what this is aimed at is taking uh recycled materials uh grinding them up and then turning them into filaments to make your own material um this is uh another project to me um this is a nice resource to be able to uh make your own uh filaments from materials use source as well as the other parts of the printer um uh so those are interested again this is in all of the machines but these are interesting parts of the machine space and also um all of these in some way have strong connections to the Fab Network we work very closely with them so then for materials uh this next group these are all vendors of filaments and they have a great range of them that are rigid flexible translucent colored um this is a filament It's tricky to print but you can print and then melt away so you can do metal casting um uh this is a link to a Foundry process to do metal casting uh um and then it's really easy to print on fabric this is an example of if you put fabric in the bed of your printer you can print on fabric as the bed and that has lots of fun use cases and then beyond that this is the link to you can actually print fabric um this is a student in my lab who developed a really nice process to mod to under extrude and by doing that you you print fabric um and not only that he he said I think a record uh he he did a print job that took a month and when you took the print job out and unrolled it from the printer it was the size of mit's biggest Sports field um so that's actually printing uh printing fabric then food you need to be careful with food so this is a link from form Labs um this is a link from prusa this is a hack a day study uh there are a bunch of issues with food uh pruning food safe is like being kosher the whole chain of producing your material your printer everything has to stay food safe um so this is a link to materials that are food safe and then something else you need to be aware of is um when you print if the print has lots of little ripples from the print layers food can get stuck in them and so you want to print with surface finishes that don't trap food so these are two good links on uh what you need to know about food safe printing then uh you have and you'll use printers in your lab uh something I recommend is uh prusa makes many of its prints many of the parts of its printers on its own print Farm they've got this massive print Farm um of prusa printers uh and uh my lab has a more modest one but I have maybe you know 10 or 15 of these and with printers coming down to hundreds of dollars for a few thousand dollars you can set up a print farm and once you've done that how you use the printer I find changes once you have sort of unlimited printers you think less about the time of the print job and you do more ambitious things in the printer once you have a job you can um send them out to um and then uh these are all vendors I mentioned who manage uh not just print Farms but many different sort of printers and so the hundred thousand dollar printers in the million dollar printers um you can send jobs to them that are much more expensive than doing on your printer but you can get access to um printers you wouldn't otherwise afford okay so now you need to send a job to a printer uh Far and Away the most common format is STL dates back to um that just that strata says 3D systems at the burst of stereo lithography it's just a list of triangles and so that's what's good and that's what's bad uh it's very easy to open and read an STL file there's no conversion issues what's bad about it is it's missing all sorts of information it doesn't know about different materials it also doesn't even know about units or Dimensions uh it's just a simple dumb format with triangles but what's good about it is if you like coding it's very easy to write so your assignment is going to be to make an object that you can't make subtractively so if you had a five axis Machine Tool you could come in and cut what I want you to do for this week is make something where you need you need to get access to internal features that you couldn't do by cutting away and the assignment for this week was done by Ling dong an incredible student so this is his homework for the class and you can clearly see how it's not something you could make subtractively but not just that all of the code to make this is on this page and so uh he's a good programmer and so each week in the class rather than using a cad tool he wrote a program and so all of his code to do it is on the page and this was done with one of the stratacist polyjet printers with a soluble support uh to make this incredible part so if you like coding you can write STL files directly beyond that plyad's color this is an emerging format that's been emerging for many years to deal with the limitations of STL and what's good is it's more General what's bad is the Committees behind it put in everything they could think of um so it's beginning to settle but it's like a container format of formats um obj is an Autodesk format but it's a convenient way to convey colors to printers then these are all 3D Graphics formats used for graphic interchange that things like color printers increasingly can handle um uh Advanced printers like the stratasis ones uh can you can talk to them with voxels rather than triangles to actually talk to the individual volume elements and that's great for really complex geometry then the most common way commands are set to the printers are g-codes we're going to learn more about that in machine week but one of the things you can do with g-codes is you don't have to print in flat layers and so something that's an emerging research area is by moving all three axes at once you can make smooth surfaces and print more efficiently than just slicing in layers and so non-planar printing is really still a research area but it's beginning to get deployed okay two more topics software and then scanning so first you you need a tool like uh mesh lab is an example uh net Fab mesh mixer all of these are tools just to deal with meshes unless you're doing voxel printing you'll be sending meshes to the printer and so they let you inspect your meshes edit them uh filter them just there are a number of different operations you end up needing to do on meshes so you want to have a good mesh tool then you need to slice and so slicing is taking your design and turning it into print commands and most of you will be using fdm printers there you're setting the path of the head um if you're using an STL printer it's the path of the laser if you're using a powder bed printer again it's the fusion path um all of these are slicers and the good I good story is they've all matured they've all learned from each other um so uh any one of these like say Cura uh uh came out from ultimaker prusa slicer is prusa's version of the slicer project all of them do pretty much everything I'm describing so they let you specify bed adhesion they let you trade off print speed versus time pick the infill pick different types of infills and increasingly they have different strategies to deal with things like the overhangs and the supports they let you grow supports that are pretty easy to remove so the printer you're using typically comes from one of these families but they're all pretty converged uh I'll do a pretty good job of that then to send it to the printer if you're using an open printer Design This is a nice open project to send jobs to the printer and then this is a nice project once you have more than one printer this lets you build um interfaces to control uh multiple printers uh let's see there's a question in the chat about who bought who so MakerBot was bought by stratasys and that wasn't right wasn't ultimaker also recently acquired by stratasys we merge them okay so so now they are like a sub-company of stratasys but we merge them interesting yeah I mean there was a lot of overlap between them and so that sounds like a big convergence okay and then um uh Michael's asking about splitting a big model into smaller models to assemble I don't know any way to automate that because I mean it's very easy to just slice it into chunks but designing the the features to fit it uh comment in the chat anybody else but I don't know a way to automate making splitting a big model into smaller parts magix can do that uh what is that magics um sorry help me find that I'm not it's by materialize materialize magic down there I see interesting okay and then the last thing is uh these are all Sites that let you share your designs and in particular all of these have ways to embed it into your site so um these let you share designs but they also include uh viewers so you can embed the viewer into your site and see the model and like uh this is a not a commercial platform this is just a a nice uh website extension that lets you put 3D content in your site and embed a viewer for that um so those are for sharing the sites and being able to view it okay uh last 10 minutes is going to be on scanning uh scanning is exciting and frustrating scanning is taking a 3D object and getting it into the computer uh there's no perfect way to do it so uh typically you get a cloud of points then you need to triangulate it to turn it into a surface typically it's not wood or tight meaning there's holes which means the printer can't print it so you need to make it wood or tight and often you want a texture to be able to represent how the surface looks as well as um uh the the geometry see Blair has another link um let's see this is a Blair is this another tool for printing big things yes okay it's uh Larry sass was involved in developing that one yep oh interesting okay I wasn't I'll add links to these um so 3D scanning uh it can be strongly dependent on how your object is lit it can be strongly dependent on the materials it can be strongly dependent on the texture um The Ideal tool to do it is um my lab has a million dollar x-ray microscope and so this let this is a fly-through of the head of the House of a housefly it actually gives you the inside as well as the outside at Micron resolution uh but is a million dollar machine um you one way to scan is by scanning a probe over the object and tapping it to feel the surface a nice way to do it is optically and this hasn't yet been done for a consumer version but but I think it's in the future here you scan a focal volume with the microscope and you see where the focal volume hits the object so it lets you scan the object without having to physically touch it um the if you can afford to destroy the object you can mechanically slice it so this is an article working out the wiring of brains and it's done by in tiny little layers removing a slice and then taking a picture and removing a slice um opacity is where you make the object disappear colloquially called a milk scanner you you pour an opaque liquid over the object which could be a person and you watch it as it gets submerged and you trace the boundary uh from that uh digitizer arms are these don't automate the scanning but what they do is they let you measure particular points and um for example in Frank Geary's shop the architect when he designs a building they take his designs and they don't want to scan everything they just want to scan the relevant parts of the design and so this this has a human in the loop and it's not an automated 3D scan but you add value in measuring just the parts you want um uh then uh let me come back to uh actually yeah let me stop on this so photogrammetry is where you take a lot of different pictures and then you combine the pictures and so these have been exploding so Alice vision is an example of one of them um uh mushroom is an example of another one of them uh these need fairly substantial Computing so I've got some links to doing it in a cloud um uh and so here's an example of I I took this Vice um I'm intentionally putting it on the carpet and I'm using the carpet as the background because it has a lot of texture um for the scanner to see and I've got it lit fairly firm fairly uniformly so there's no Shadows or bright lights and then I just took a whole a lot of pictures and then you throw this at this tool and then what it worked out here is it figured out where I took all the pictures from and then it gave me a 3D model of the object I scanned now you'll see the 3D model is pretty good it got most of it but it's not exact it missed a few parts of it so photogrammetry depending on what you're doing gives you a good model but typically there's some um cleaning you need to do um so these are all versions of photogrammetry software um some commercials some open source um some that run on your phone some that need the cloud that just start by taking pictures um speckle is rather than just taking pictures where you put a dot pattern on it and then um use it and so historically the connect was an important commercial product that did it and then reconstruct me um is uh scanning software for that lasers are where you rest or a laser and you see where the laser hit it and Fab scan is a open project to make a laser scanner uh where you where you you aim the laser and then you look to see where the laser hit it a structured light is where you project a pattern on the object and you look at how the pattern deforms and so um let's see uh this is an example I see um yeah this is an example I did a while ago where uh what I'm doing is I'm using a laser projector a little Pico projector I I'm putting out lines and then I look at how the lines bend on the object and then you can combine them um to get the math of the object uh lidar is where you measure the time of flight for a laser to go and come back and with the single laser you rotate it around um but there's a number of emerging products and every everybody keeps buying everybody in this world uh where there are cameras where each pixel in the camera instead of measuring light actually measures the time of arrival of light and so you send out a light pulse and then it gives you a depth map um and these are really being driven by phones for augmented reality we'll talk about later uh there's a tremendous need now for phones that can measure 3D geometry so right now these are in Rapid flux these 3D imaging cameras but they give you one projection and then as you move it you can pull a scan from that then um light stages are I'd say the the most powerful kind of scanning um the biggest light stages are a room full of lights and cameras and this is a colleague Paul deppavec who's done beautiful work on light stage scanning and uh um he did this wonderful project where he made a tabletop version so what he's going to do is this is a ring of LEDs and here's a shiny object that's hard to scan optically then he has an array of cameras here he's going to spin the camera around spin the lights around and he's doing what are called spherical harmonics he's putting out a range of Illumination around the volume around this object then the cameras look at all of the reflections so what he's doing is he's lighting it from many different directions Not Just One Direction then he does interesting math and if you want to do computer Graphics you need to separate specular from diffuse scattering you need to separate surface from subsurface scattering you need to describe the texture of the material and so by rotating the object and the light source he measures what are called light fields and so he's not just measuring the geometry he's measuring the full Optical scattering properties of an object and then once you've done that it then lets you separate all of these and it lets you completely re-render the object photo realistically and so these are used in Hollywood special effects um digitize a person and make a photorealistic actor um that's the higher highest performance and then finally the last one I'll mention and this is a very active research area um is uh um what's called slam which is simultaneous localization and mapping and so this is once you have photogrammetry or a depth camera as you move around a room what it's doing is it's continuously building a map of the environment you're in and again that's really being driven by augmented reality that we'll talk about in uh later in the cycle so you should take away from that there are many different types of oh let's see sorry um a link I skipped over is um uh these are low-cost um structured light scanners so uh for entry level 3D scanning um these do structured light with a built-in app and so this is a good kind of just entry level uh scanner um uh versus let's see I don't have it here the um uh this is a thirty thousand dollar um laser Scanner with uh gpus um uh built right into it but something like this is a good just uh completely built-in uh entry-level scanner um yeah there's uh Quentin uh for his final project um uh made a photogrammetry uh 3D scanner um as a final project so take away from that there is no ideal solution to scanning but there are a lot of interesting options to experiment with and there's lots of room to develop these in your lab and extend them so as a group uh characterized designer rules um uh uh see yuichi is adding a link to um uh his his lab scanned nice okay then individually the scanning object is just scan any object you know optionally you can print it but uh um scan it then I want you to design an object make it small only a few centimeters because you're going to be limited by time on the printer and the design challenge is make it so you can't make it subtractively so it has to have revolving Parts nested Parts overhangs uh it's it's an exercise in creating geometry that you couldn't just do with a milling machine and you know think ahead to your final projects so it can be as simple as a case for part of your final project but but it can involve for example tabs or nesting or features to snap the case together as part of the design study okay okay so then you're going to print this week and there is a recitation on Monday and this is going to be an intro to programming you don't need this if you're an expert programmer but for beginners this is just going to be across all the languages you're we're using uh an introduction to programming uh and then next week we'll go back to electronics where you're going to design your own Dev board so by the end of this week you should appreciate the strengths as well as limitations of 3D printing and I'd say even more so strengths and limitations of 3D scanning but be comfortable going from digital to physical and physical to digital that way okay happy printing see you all in a week bye bye hey babe [Music]

2023-03-01