Understanding the Tesla Model S Performance Motor

Hello, I am Professor John Kelly and this is the WeberAuto youtube channel. Today I am excited because we are going to go through a performance motor from the rear of a Tesla Model S P90D from the model year 2016. Now our school here, our automotive program actually, has a 2018 P100D, but they wouldn't let me disassemble that one so I searched all over tried to find a rear-drive unit which is the motor the gearbox, the inverter, everything all together and as you can see here in this photo. I finally found one that we could afford. It is a burned-up one, it was a from a car fire and I thought "Well how hard can it be to just clean all that smoke and soot off of there" and I will tell you it was a mistake to buy. Never buy anything that's been from a burned vehicle. We spent way too much time trying to clean this thing up and of course,

it has some damage to the electronics, but I wasn't so concerned about that as I was the gears and the some of the neat things that I like to look at in my videos and so let's get started looking at the pieces of the performance rear motor on a Tesla Model S. I've got the housing right here of the gearbox, one half of the housing, the other half of the housing is on the other side of the stator housing back here on the other side of the bench, but inside of this housing right here we have places for three bearings to sit. We have places for the three-phase cables from the stator to come through, and then we have two coolant passages, that we'll look at a little bit later, and it and as a matter of fact I want to divide this video into four separate sections. So section one that we're doing right now is the gears and

the motor, Section two will be some unique things about these bearing,s they're pretty incredible. Section three will be on lubrication, these bearings require some special lube in order to withstand the high rpm that they operate or can operate at, and then the fourth section will be on the cooling system to keep that oil cool so that the bearings will continue to survive along with the rotor and the stator to keep everything cool. As with any other transaxle transmission we have to have a final drive gear, the differential unit, so we have the differential case from this P90D Model S. and the very first time I split the case and got this thing apart, and saw this gear sitting there sideways in this gear reduction unit, some people call it a transmission, it's a gear reduction unit, it does not shift, it's a one-speed gear reduction unit, but I started laughing because this has the biggest bearings I've ever seen on a differential of a front-wheel-drive or rear-wheel-drive transaxle style with the helical cut gears. So this ring gear is monstrous, it's a 213-millimeter diameter ring gear and it's 50 millimeters thick, that's incredible, and it's held to the differential case with 16 bolts which is pretty unusual. There are other cars, front-wheel-drive cars, that vans and so on that

also have 16 bolts holding that ring gear on but they're not 50 millimeters thick either, but the thing that really made me laugh was this bearing back here. This bearing is 110 millimeters in width and it's just a monster and so we'll take a look at some of the specifications on these bearings here in a little bit but a differential is a differential this thing operates just like any other open differential and the maximum, well let's see this differential has 78 teeth on it, and the maximum rpm that this differential rotates at the top speed of this 2016 P90D Model S at 155 miles an hour this is only spinning at 1841 RPM, so this is the slowest spinning part in all of this gear reduction unit, so by comparison I've disassembled two other EV or Electric Vehicle gear reducers, and I just want to show you uh how they compare to the Tesla performance model right here. Now I know this is comparing apples and oranges because this is a performance model and these other two are not but this next one that I have right here is from a Chevrolet Bolt EV and it has, instead of 16 bolts holding the ring gear on, it has 12. It has some decent sized bearings but they're smaller than the Tesla one and

look at the height difference in the ring gear, it's only 34 millimeters thick rather than 50 millimeters thick, and then if we bring in the little Nissan Leaf, it has eight bolts holding the ring gear on and it only has a 32-millimeter wide ring gear right there. So I know these vehicles were not made for performance and I'm not trying to make fun of them or downplay them, I'm just showing you how big this Tesla performance differential is compared to other EVs on the market, and as a matter of fact in any other front-wheel drive or rear-wheel drive transaxle that's out there. Okay, here's a few other photos showing the differences in the physical size of these differentials and ring gears now let's put this Model S differential into the gear reduction unit housing with these big ball bearings. They just slide down into the housing but it's a lot harder to do than it sounds, so once that's fully seated we can move on to the next gear which is our countershaft and it has two gears on it it has the pinion gear that drives this ring gear here, and this pinion gear has 25 teeth, and the ring gear has 78, and if you take the 78 teeth on the ring gear and divide it by the 25 teeth on the counter driven gear then we get a gear ratio of 3.12 between these two gears, and then it also has a counter drive gear that has the same 78 teeth that the ring gear of the differential has except they're much smaller, and they are driven by 25 teeth that hooks to the motor shaft so let me set this counter gear down in now, take my sticker off just like that put my sticker on the top here instead of the bottom. Alright, at the top speed of the vehicle at 155 miles an hour or 250 kilometers per hour this shaft spins at 5743 RPM which is 3.12 times faster than the differential

by the way, the differential turns the same speed as your rear tires so on our P100D and on the P90Ds that I've researched, the rear tires are a little bit taller than the front tires and so it's just the rear tires that this differential will spin at the same speed as. Okay so uh the next shaft that we have I don't know the exact name I just call it the motor shaft because this shaft connects directly to the motor and it has 25 teeth on it that drive the 78 teeth of the counter drive gear so we get another 3.12 gear reduction so I'm going to take this shaft now the motor shaft and put it down in its bearing just like that. Now these bearings on the motor shaft have to handle the rotational

speed of that motor shaft and of the motor itself because they're all connected together and we'll take a look at the motor here in just a moment but I did the math for the tire size that come came on the rear of that 2016 P90D, and at the 250 kilometers per hour or 155 miles per hour this shaft in these bearings is spinning at 17,919 RPM it's almost so almost 18,000 RPM the motor is spinning if you run your vehicle up to the top speed, which of course you better do on a track somewhere rather than breaking the legal speed limit but those are some incredible speeds. Now of course most people will never get anywhere near those speeds but those speeds require special lubrication pumping up the special oil through these bearings to keep them cool at the higher speeds, and special cooling system to keep that oil cool. So anyway now we've got, if I tip it up on its side here, we just have our motor shaft spinning the counter drive gear spinning the counter driven gear spinning our differential our differential case and our tires and that gives us an overall gear reduction of 3.12 from here to here multiplied by 3.12 from this gear to the final drive which gives us an overall gear ratio of 9.7334:1so 9.7344 rotations of the electric motor to one rotation of the tire .

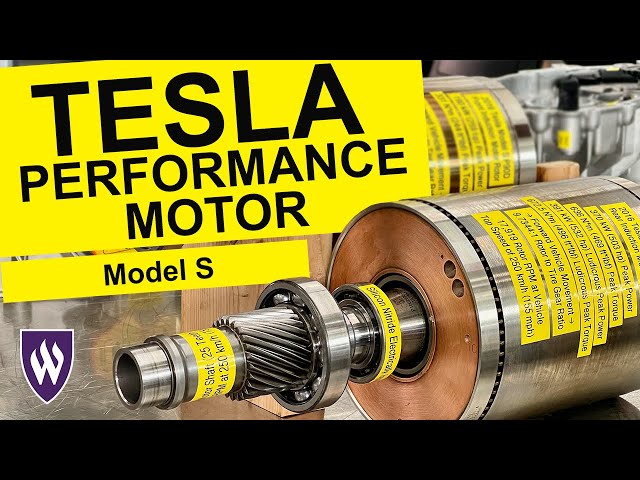

All right now let's bring in the electric motor. This motor weighs 27 and a half kilograms just a little over 60 pounds which is more than I'm able to just toss around and so I'm going to set it in some "V" blocks made of wood here to show you a few things about this about this rotor. Okay uh the first thing is that the P90D this the version of this rear-drive unit was only from 2015 through 2016. the part number of this rear-drive unit ends in the letter Q and the part number of the rear-drive unit in our 2018 P100dDends in the letter R, so there's been one more revision somewhere for the increased performance of the 100 kilowatt hour battery, but I would imagine they're very close to the same, maybe some differences in bearings, so let's take a look at some specifications here this is a three-phase four-pole AC induction motor. This has no permanent magnets in it, this is an induction motor.

It is rated at 370 kilowatts or 503 horsepower unless you put it in Ludicrous mode, in which it goes up to 391 kilowatts or 532 horsepower. It has a peak torque of 469 pound-feet of torque or 636 newton meters, and that is in Ludicrous mode I could not find any torque specs for regular mode so if any of you know what those are or if these numbers are incorrect i've had to go back in the wayback machine on the time machine on the internet to find some old Tesla documents to get these specifications, i didn't pull them off anybody else's website, this is Tesla only specs that I found now as I mentioned before we have a gear reduction from the motor to the tires of 9.7344, I think I said 334 before but this one is correct the 9.7344:1 and that's rotations

of this rotor, it takes 9.7 of them to get one rotation of your tires and as I said before also this rotates up to 17,919 rpm at 250 kilometers per hour. Now uh when I first heard that number the 18,000 rpm, I thought, well I wonder what kind of bearings that is using, because the later Toyota Priuses have motors that spin up to 17,000 rpm at their top speed but their top speed is only I forget it it's just barely over 100 miles an hour I believe, and this goes up to one 155 and the new Model S that was just announced goes up to 200 miles an hour, so I'm really curious to see what they have for bearings, but so there's some very unique things about these bearings. There were some bearing failures early on on the Model S and they switched to what everybody calls a ceramic bearing, it is a ceramic, it's called a silicon nitride according to SKF's website. Now SKF is the bearing manufacturer for the majority of the bearings in this gear reduction unit and here for the motor these bearings the ball bearing portion of the bearings are made of a non-conductive material so if i turn this around here let's zoom in so you can take a look at the balls in the ball bearing see how they are not the shiny silver typical ball bearing that you would see in any other bearing there's kind of the dark color that is that silicon nitride and both front and rear bearings on this motor are non-conductive so there's no electrical current that can run through there no arcing that can occur and damage the bearing like what happened on some of the earlier models from what I read the balls are 60 percent lighter than the previous ones which means they have less mass and can spin at higher rpm, they don't expand like steel bearings do and so they can run at higher rpm it takes a special lubricant. there's a special seal that I've pried off

that goes on the outside so the seal is this dark seal and this is the lubricant that's on the the back side of it but normally that would be right here covering up those ceramic balls so that you couldn't see them, but I wanted to see them so very interesting bearings these bearings have no external lubrication fed to them, they have no external cooling system fed to them, and this rotor does not spin in oil transmission fluid coolant, it's a dry spin inside of a sealed housing. Okay as you can see the copper color here on the end of this rotor, the rotor does have a copper core, you can see some of the connector bars on either end they appear to be just straight through without being tilted or twisted on the front of the motor we have a speed sensor reluctor wheel right here this two tooth ring, on an induction motor we just need to monitor the rotational speed of the rotor of the induction motor, not its actual relative position, so just need to know the speed. Both bearings, this one here and the one in the back we just looked at, are the same part number from SKF. I tried to find this bearing on their website it is not there. Other bearings of the same type are there but this part number is not available on their website or in their catalog from what I could see. let's take this rotor and

put it into the gear shaft now for the rotor and see the whole gear train put together. Okay that's quite a chore putting that in there but as you can see it just connects directly to that motor shaft and as it rotates 9.7344 times we end up with one rotation of the final drive unit itself that hooks to our cv shafts cv half shafts. Here's the end of a cv half shaft the tripod or tripod joint that just slides right into a side gear and there's another one that comes in from the other side, so as your electric motor turns so so do your cv half shafts and your tires all right so this is pretty basic stuff there's as far as the gear train is concerned there's nothing magical about this other than it's just big and heavy duty but as I mentioned before these bearings to withstand the high rpm that they have to at the maximum vehicle speed and even faster on the newer ones have to be some special bearings now I mentioned before that the Toyota Prius MG1 and MG2 rotors on the latest generation 2016 and above can spin clear up to 17 000 rpm but there are these little tiny lightweight rotors compared to this thing, these bearings have got to hold the big heavy rotor and handle a whole bunch of torque at the same time, so an interesting thing is that the rotor itself is only supported by these two little silicon nitride deep groove ball bearing, non-conductive bearings, and that just spins inside of the stator assembly back here. Let's take a look at the stator for a moment. We have a stator housing cover that fits right here and we have a bearing, a non-locating bearing, so it moves just slightly as the rotor heats up and cools down, and then the locating bearing is all the way in the bottom of the bore here. The locating bearing is the one that holds solid

it doesn't move with expansion and contraction of the metals as they heat up and cool down. This is a 60 segment stator assembly, it has 60 segments. I'm not sure how many poles it has i'm not sure how it's wound but if any of you know let me know because I couldn't find anything anywhere as to how many poles it has, i know the motor is a 4-pole. This stator assembly with the housing that it's in weighs 125 pounds or 56.7 kilograms. This thing is heavy very heavy it's not something you can just toss around easily and especially if it has the rotor inside of it. On the other side of this stator

housing if we turn it around we've got the other half of the gearbox so our differential locating bearing that holds solid and doesn't move is right here, our countershaft locating bearing goes right here, and our motor shaft locating bearing goes right here. Now notice we've got an oil pump, there's an oil pump pickup tube right here there's a magnet for any metal particles in the special fluid in this thing and then we've got kind of a windage tray to keep the movement of the ring gear from sloshing up the oil that's trying to be picked up by the oil pump. So the oil pump has this 23 tooth driven gear right here and this is driven off of that 78 tooth ring gear which means it's overdriven by the ring gear about a little over three times, so whatever ring gear speed is this oil pump spins three times faster than that and this oil pump has one job and it's not to lubricate all these gears it's to keep those bearings alive at high rpm, so if we look at the output of this pump it has this kind of a t-shaped except with three outlets uh piece coming off of it this piece right here that goes back into this housing for the bearing feeds three evenly spaced oil holes that go into the back of the bearing and then force fluid through to the front and that's on that motor shaft bearing and then this tube right here sprays across to the other bearing so our motor shaft has two different bearings on it, and then the center piece right here sprays on the motor drive gear because this is the gear that's going to have all that torque put to it, so the big deal here is that the rotor of this motor spins on those two little lightweight, non-lubricated, non-externally lubricated, non-cooled ceramic silicon nitride bearings, but it turns the motor shaft and the motor shaft has to handle all of the thrust torque from rotating and turning that counter drive gear and the counter driven gear in the end then that gear drives the ring gear. So with what did we say um 636 newton meters maximum, 469 pound-feet of torque, on the rear motor here, that's a lot of torque, and these bearings have to, they have to be very strong to be able to handle that amount of torque, and they require a lot of lubrication and this pump as I mentioned only has one job and that's to keep those two bearings lubricated on the motor shaft and also to spray oil on the motor shaft drive gear where it meshes with the counter-driven gear. So that's pretty incredible when I first opened this up and I saw that oil pump I thought oh it's lubricating all these bearings and whatever else, no it's just the motor shaft uh bearings and the gear so when I looked up the part numbers for the two bearings on that motor shaft have to spin clear up to 18 000 rpm, I just wanted to see what the specifications were on the bearings.

Were these also a special silicon nitride bearing or not? and they're not, they're, it's a special high-quality bearing, I think they call it their Explorer Series bearing, but an interesting thing in the table I found on these is that one of these, well there are two speed ratings for each bearing. There's one called a reference speed which one of them is at 20,000 RPM, the other one is at 18,000, and then there's a Limiting Speed which is a mechanical limiting speed without any doing anything extra, with no external lubrication, or anything of 13,000 and 11,000 on those bearings, but then I saw a little note that said you can run bearings higher than those speeds if you do some special things, so the catalog says it is possible to operate a bearing at speeds above its reference speed, its adjusted speed, or even its limiting speed. So we're running these bearings above the limiting speed, it says before doing so make sure you do a thorough analysis and take whatever further measures may be required such as the use of special cage executions or consider using high precision bearings.

regarding management of the effects of increased speed consider the following options. So listen to these options and let's see what how they compare to what tesla did here control the resulting increase in bearing temperature by additional cooling so this pump here running fluid constantly through these these two bearings uh gives it the extra cooling compensate for any reduction in bearing clearance resulting from increased bearing temperature so the bearings get hot and then the balls expand and we don't want them binding and so the bearings that are in these are special high clearance bearings there's a clearance that's above the the regular bearing and then there's two, three, four, five, other things two of the most important ones in regard to the Tesla motors are: Ensure that the lubricant and lubrication method used are compatible with the higher operating temperature of the cage execution, so as i mentioned before it's a special lubricant this isn't just gear oil, this isn't just regular automatic transmission fluid, Tou need to stick with the tesla recommended oil for this and then check that the re-lubrication interval is still acceptable particularly for grease lubricated bearings oil lubrication may be required and so Tesla is using oil lubrication. so they've done what they need to do to run these bearings at higher speeds and of course you're not going to be running at top speed all day long every day and so it's probably not a huge concern for most people but it's very interesting the things that they have done in this gearbox. All right now as far as lubrication I've mentioned that takes a special lubrication I don't know what it is i don't know where to get it other than at a tesla service center so if any of you know what it really is and don't just tell me it's Dexron -VI, I've read that I don't believe that at all (See corrections in video description) let's share in the comments below what it is. All right now as far as draining the oil from the gearbox, right here on the bottom of the gearbox there's a drain plug and right here on the side, there's an oil fill and oil level check I assume but the Tesla service information that I've accessed is less than helpful. Alright on this housing let's take a look at a few other things while we're here there's a vent here on the gearbox side and then there's a separate vent for the inverter the power electronics portion of that I mentioned that this drive unit is out of a car that burned down but I was able to clean up the tag enough that we could read the word Sport right there and that's just like the the tag in the P100D that we have it also says Sport up here in in the part number and description above that so this is the the Sport version of the motor I mentioned that vent for the gearbox this drive unit has three different areas that are sealed off from each other. We have everything

that's in the gearbox that we've looked at and it has the special gear oil in it as we've discussed, but that needs to be totally sealed from getting into the inverter area where the electronics are, it needs to be totally sealed from the anti-freeze cooling passages that run through this drive unit as well, and it needs to be sealed from getting in where the rotor is because that's a dry area. and so there's special seals and o-rings all over the place to keep those separated and so if you're planning on taking one of these apart and then putting it back together to reuse it you better keep all that in mind because one leak of one especially any type of fluid into the inverter area is going to cause some some major problems. okay well let's look at how this drive unit is cooled. if we look at the back cover of the stator assembly, if you look at this photo of our P100D here on the hoist you can see that it has an inlet hose coming from the front of the vehicle and I haven't traced where it comes or where it goes to in the front of the vehicle but i'm sure it ends up at the chiller eventually through some sort of a switching valve and a radiator to get cooled down and then it comes back. We have this piece right here and that inlet hose connects right here now since this is out of a burned up vehicle the plastic inlet fitting melted off but this is where the coolant would come into this drive unit. Now as it comes into the drive unit it goes two ways, one way is that it goes up

and then all the way down the middle of this hollow shaft right here and this hollow shaft with a seal sticks down inside of this rotor assembly the induction rotor now an induction rotor runs hotter than the internal permanent magnet motors that a lot of other vehicle manufacturers use so it runs coolant down through the center of the rotor where it's blocked off at the bottom and then it has to come back up around the outside of this tube where it goes through this seal and then it goes up and out the top right here and as it goes up and out of the top there it connects to a pipe that we'll look at here in a moment. So that's one direction that coolant goes from that fitting that you saw in that photo the other direction is it just goes down and through this fitting right here which connects to this passage which on the other side is just a straight pass-through passage so you can see you can see light through there and then that feeds right here into the bottom of the stator so the stator is cooled all the way around by anti-freeze, a special antifreeze that tesla wants you to use, so it comes in the bottom goes up and around, and then if we switch this around here you can see that it comes out on the top right here where it then goes through our gearbox housing right here and down to feed and cool the inverter IGBTs that run the three-phase power to the stator assembly and we'll take a look at those here in just a moment. The next part of the cooling system is that with if we put this cover back on here right there and we get our inlet and our rotor cooler, oh by the way this other hole right here is for the speed sensor for that toothed wheel on the top of the rotor assembly, but what i wanted you to see here is that as the coolant leaves the rotor and comes up through that hole there's a pipe right here and this pipe plugs into that outlet coolant from the rotor and it comes up front here to a hole in the gearbox where it goes through right here and goes into the other half of the gearbox so now we are ready to look at the cooling passages in the other half of the gearbox .Oh by the way, this wire right here coming out by our three-phase connectors for the stator has four wires, two blue and two green. I believe these

are stator temperature sensors, there's probably an inlet and an outlet temperature I believe. Okay, that pipe with a little hole that went through the other half of the gearbox lines up with this hole right here and it comes through this coolant passage I've got labeled coolant flow going down, we've got the coolant flow coming from the stator going through and now let's look at the other side. Okay the coolant from the stator comes in and goes through this passage right here and it ends up on the inside of these three sets of holes right here, so these three inside holes are where the coolant from the stator comes. now notice there's a temperature sensor right here measuring the temperature of the coolant coming from the stator, there are three sets of these holes because they cool three sets of IGBTs, capacitors, and other electronics, that are all here to control the current and the voltage at the three-phase connections at the stator assembly itself. Now I've taken this cooling passage apart on this IGBT module, and as you can see there are all kinds of little buttons, whatever you want to call them, I don't know how to describe them sticking up heat sinks to transfer heat from the 32 IGBTs that are on the other side here, and you can see this definitely got burned up, into the coolant as it comes through now if we compare this housing with the two the two fittings here this housing is going to bolt right there and so if the coolant comes in on the inside one then that's this hole right here, so that is going to come in and go up this channel right here spread out to these four holes and come up across all of those little heat sink pins and then go back in and come out on this hole right here which is the outside hole on these four or three cooling passages and once it goes in to those outer ones you can see, well you can see a cast channel where the coolant comes in from the stator then it cools all three sets of IGBT modules and then it goes out through this passage right here and there's an outlet coolant temperature sensor right here also and then it goes over and there's a hole right here and notice there's a whole bunch more heat sink pins right here on the gearbox side and that little tiny hole that came from that pipe back here on the stator housing feeds coolant into this hole and then the coolant runs through all of these little pins where there's a heat exchange between the hot transmission oil and the coolant so it transfers heat into the coolant and there's a there's a plate that fits right here that bolts down, you can see in this photo here from the one in our car what it looks like in the car, and then it has this fitting right here that bolts right there that is the outlet to go back inside under the back seat to a water pump where it's pumped through the onboard charging module and then back out to go back to the front of the car. So we've got the cooling system for this the stator housing, we've got a cooling system to cool the induction rotor, and as I mentioned before they get a lot hotter than internal permanent magnet rotors because they have current running through them where the permanent magnet ones do not. And then after the stator and the rotor are cooled

the stator fluid comes in and cools all the IGBT modules and then goes out of the gear unit here and then the coolant from cooling the rotor comes in over here and helps cool the gear oil and then it comes out this same fitting here underneath the car to go up front to have the heat removed from it or added to the passenger compartment heat from what I have read and understand but I have not physically traced that to verify that that's true. Okay so with all of these IGBT modules bolted up here in the shape of a triangle as you can see here in this photo, the last part to bring in would be the inverter cover itself and so it bolts on right here and before I knew anything about Tesla motors drive units I thought this was another electric motor but even though it's round like the stator assembly on the other side it's not a motor it's just a cover for the electronics that are in there. Now on the front cover for this inverter assembly cover we have two great big holes right here for the positive and negative high voltage cables from the high voltage battery underneath the car so they come in and plugin right here let's see this one is the battery positive it's actually cast into the the cover and this is battery negative and then there was before it melted out a low voltage black electrical connector there for data communication, power ground, wake up signals, and whatever else there may be, drive accelerator position, and so on I'm sure other information sent to the inverter to drive the vehicle. So this is the inverter cover. Okay we've looked at a lot of stuff here on this 2016 Tesla Model S P90D rear drive unit I believe it is very very similar to the P100D in the 2017 and above and of course the new released one that's got the two individual rear motors is totally different that has just been released or announced. but I have, for this same 2016 Tesla, I have the front electric motor that

we'll look at and it's different, I mean it's similar but it's got some major differences and then I've got all the power electronics, everything all the high voltage cables all the high voltage electrical components on the Tesla Model S, we're going to lay it all out and show you what's connected to what and how it works and then we'll do the same thing for model 3. I've got a rear motor a front motor and the power electronics to go with that. If you've enjoyed what you've seen here today and you feel like donating to the Weber State University Automotive Technology Department there's a link in the video description at the bottom, thank you for watching

2021-02-23