Mod-01 Lec-28 Turbine Blade Cooling Technologies

You. Have just had a good exposure to the various. Fundamental. Heat transfer. Science. Panel, indication. How that science. Of heat transfer, is used for, actual. Flow turbine cooling, in. Today's lecture we'll. Be looking at the, technology. Of. Gas. Turbine, cooling. The. Cooling of, axial flow turbines specially, in aero engines, have been in vogue for nearly, 50 years now, so. The cooling technology, is indeed 50 years it did not start with cooling technology, axial flow turbines in. The early era, where. Without cooling technology. However. For. Nearly 50 years now various, kinds, of cooling technology, have been used and we. Will look at this, entire generations. Of cooling, technologies, in today's lecture. In. Fact all, kinds. Of those cooling technologies. Are still in, use today. Because. You need some. Of those cooling technologies. Even. Today in simple. Gas, turbine engines, whereas. More, modern, or more ambitious. High-performance. Gas turbine engine may, require a more advanced, cooling system. So. If you are creating a simple, gas. Turbine engine. Old-fashioned. Cooling technology, would still be useful. And. Hence. Those. Technologies. Are still in. Use in some, form or other in. Many gas turbine engines, especially. In, aero, engines, even. Today so. We will look at all those technologies, that. Have developed over last 50. Years, now. As I mentioned the cooling technology, is, based. Primarily. On the science of heat transfer. The. Idea, of. Cooling. Actually. Came. From the. Gas turbine. Thermodynamic. Cycle analysis, which. Very clearly showed. That, if you can increase the, turbine, entry temperature. You would get a substantial. Benefit, in terms of the work done by the cycle, which. Of course in in terms of gas turbine engine means more. Work done by the turbine more work available. Either. For creation. Of thrust for aero engines, or, for, running a propeller, which, creates, thrust or, for. Land-based application. It simply means that you can get more power output, out, of the single gas, turbine engine, so. Those fundamental. Signs, of thermodynamics. Finally. Bore. Down on the fact that you. Need to have cooling because the. Material, science. Was. Unable, to go beyond, a certain level to provide material. Or, alloys. The metal alloys that. Could withstand temperature. Beyond a certain limit which is roughly of the order of thousand. Degree, K. Now. Beyond that it became very apparent that. Ordinary. Material. Technology, is, not going to really, be. Really greatly helpful and, in, which case additional. Techniques are required if, you, want the turbine entry, temperature, to go even higher, and. That's. When the cooling technology. Came, in and of. Course the entire field of heat. Transfer, had. To be utilized so, in today's class, we. Will look at the technology, in, the last class you had exposure to the science. Of heat transfer, and. We. Have done all the aerodynamics. That is necessary, on axial flow turbines so, in today's class let's, take a look at various. Kinds of actual, flow turbine cooling, technologies. Now. Much of these cooling technology, does indeed. Involve, a lot of. Engineering. You. Will see that lot of things are engineered, in. Signs. Of a transfer, creates. The basic, fundamental. Basis as I, mentioned, thermodynamics, showed. Us the way that you need to have high. Turbine. Into temperature, which. Then requires cooling, which you the science of heat transfer, and then, there is a whole lot of engineering, the thermal engineering, the. Mechanical. Engineering the, manufacturing, technology. All. That comes into picture and we. Will have a look. At some of these technologies, in. Today's lecture one. By one let's. Take a look at what. Are the fundamental, issues involved, and how, the whole thing has developed, over, already. More than 50, years. If. You look at the, graph, which is available you. Know in many books probably easily, see that in. The early era in 1950s. Or so most. Of the blades were actually, uncool, blades, so. But. They could take up. To about thousand. Degrees centigrade or so and then. From there onwards, if you are aspiring, towards, higher turbine, entry temperature, you, have to resort. To some kind of cooling technology, beyond. Other ways the turbine in inlet temperature, could not be, improved. Upon and. Irrespective. Of what material. You use the material, technology, was. Not quite. You. Know helping the matters, so. A simple, cooling technology, was used in which certain.

Amount Of cold, air, was indeed passed through the blade this, provided, a little bit of cooling of the order of, 25-30. Degrees to, begin with and that, was quite often sufficient to, raise the temperature by 50 degrees or thereabout, and slowly. The temperature, started rising as the, cooling, technology. Improved. Upon it's. Basically, an engineering. Method. Coupled. With the heat ron's for signs of heat transfer, and, as, a result of which the. Temperature could go up to near about 1400, degree or so and then. Of course people, realized that you, need more. Complex. Cooling technology. To. Go higher up and hence. More complicated. Cooling technology, came which we will be talking about in today's lecture and. Hence more sophisticated. Cooling system, came in which involved, film cooling and then. Inject. Impingement. Cooling so. On and so forth which, has taken the. Turbine. Entry temperature, to near about 2,000, degrees so. Very. Modern gas turbines, do have turbine entry temperature, very close to a 1900. Or 2000. The. Material, as I mentioned the material technology, has not really helped, matters a great deal over here and. The. Projected, trend that was shown earlier and, by now we should have reached values, of the order of, 2200. Or 2300. Degree K that. Has indeed, actually not happen, and. One. Of the reasons is some, of the cooling technologies, that were projected and we, will be talking about it in for, example transpiration. Cooling those. Kind, of cooling technologies, have not matured, one. Of the reasons again is the material, technology, the, new material, the. Porous material, which was to facilitate. Transportation. Cooling. Has, not really happened. And as a result of which. The. Cooling technology, did. Not project. Beyond. What, is shown, here and this projected. Development. Not. Really, quite matured, there's a lot of research still going on and. We. Are not quite, as yet crossing, the 2200. K mark. In, actual, commercial. Applications. So. That is where we are we are near about 2000. Or so and that's, good enough for us actually to, use, in most of the modern gas turbine engines, and we. Shall see that since, the pressure ratio has gone up the. Efficiency, of the turbine has been actually. Upgraded. Hugely, through a gradation. Of compression, ratio and this. Up gradation of turbine entry temperature, coupled. With the high compression ratio has, given gas, turbine engines huge. Efficiency. Boost and in terms of fuel. Saving, there, is a huge fuel saving in the engines, so, turbine entry temperature, boost actually. Is known. From, fundamental, thermodynamics, to, give better. And more efficient, engines. And provide. More, power, now, if we simply. Summarize, the whole thing in, the, fifties the, blades were uncooled. The early era of gas. Turbine engines and as. A result the temperatures, were somewhere around thousand, to 1100 K and, then, of course, the. Cooling. Technology, came which were internal, one or two past cooling, we. Will look at this one or two past cooling very, soon, today. And, and. The temperature, could go up to about. 1200. To 1400 K that's about, 150, degree more we. Are possible, with cooling. Later. On the cooling technology. Developed. Into internal convection. Cooling, which. Allowed. A lot, more coolant. To be used a lot more elaborate, cooling system, and temperature. Could be pushed to 1300, to 1500 K and. Then. Came of course the film cooling towards, the end of 70s. Which. Existed. Along, with the internal convection. Cooling so. Film cooling plus internal, convection, cooling push. The turbine. Inlet temperature, to higher than 1600, K and, then. Of course the, impingement cooling matured. The. Idea. Which has been around for, a long time and, has. Pushed their temperatures, now to close to 2,000. K they, are about the. Whole thing has kind of. Stagnated. A little because, the transpiration, cooling, has. Not quite matured. It has been as an, idea it has been around for nearly 50. Years it, involved. Micro. Channel cooling. Methodology. The, science of which is well known but. The technology, is not quite available, as, of today and the. Porous material, that can withstand the, stresses you know turbine. Blade has, also not quite matured. Of today to. The best of our knowledge so. The. Turbine technology has. Matured hugely. Over a period of 50 years and, has. Resulted in engines. That are more powerful and of, course which, are indeed. Smaller in size. Now. When we talk about our, wine cooling the, first thing that comes to mind is what are you cooling, you.

See The turbine is. Processing. Gas which is hot and of. Course high pressure. But. The blade feels, a temperature. The feeling of the blade here is the important, issue the. Blade feels a temperature, which is not same as the turbine entry, temperature, so, if the turbine entry temperature, is T zero one and, the. Blade, exit. Temperature, is T zero two what. The, blade would feel is an. Average, of the two, minus, the rotating. Kinetic, head which. Is shown as you. Mean square, by twice CP, of the gas which, is passing through. Plus. The, degree. Of reaction. Factored. In here now, this gives rise to the, situation. That. The, blade, temperature. As felt, on the blade surface average, blade temperature, is. Something, quite different from the gas temperature, so. Gas temperature, is not what the blade feels the, blade feels a different temperature. Arguably. And as is quite obvious, here it, will feel a temperature, lower, than the gas temperature, so. The requirement, for cooling, is not with respect to that gas temperature. It is more with respect to what the blade actually, feels. So. That. Is the temperature that has to be cooled. Through. Cooling technology. The, science of heat transfer, that you have done in the last class we. Can simply bring in here the, fact that the heat transfer coefficient is equal to. The quantity of heat to be transferred at, any local, point on, the, blade on the, blade surface at, the location, of the blade which, is normally given code, wise. In terms of often xyc, on, the cord and, the. Local surface area, over there the, temperature, differential between the hot gas and the surface as we have just seen the blade, surface temperature, is indeed, less than the hot gas, temperature. And it. In vary from the local point to point on the blade surface and, then. Of course the, time that is required to. Affect. The heat transfer, quite often the heat transfer, is expressed, as we have done in the last class in, some detail in terms of nusselt number, and they. Are known to be proportional, to reynolds. Number and prandtl number, this, is also a, semi. Empirical relationship. Which has been developed, initially, for simple systems like. Flat plate and nusselt. Number is directly, related to Reynolds, number and Prandtl. Number for. Simple systems through some. Constant. Terms, which. Are used to create. This semi, empirical, relationship. Now, this is the kind of science. Or technology that, one, would need to bring, forth in, the turbine cooling. Business. Now. Let's look at the technology. What. Happens, is when, you have a, blade, this is a typical carbine blade and you are looking at a diagram which probably you, had had a look at in the last lecture also, but. Let's discuss this again the. Flow comes in here, and at, this point you have the leading edge which is the stagnation. Point, now. What happens at the stagnation point the flow comes to a halt when. The flow comes to a halt thermally. That. Place. The. Total. Temperature is, equal to the static temperature which. Means this, point of the blade the. Blade feels, the, entire, total, temperature of, the gas flow that. Means the static temperature plus, the kinetic head, that, the gas is carrying, the, entire thing, is felt over here at the stagnation point so. The stagnation point is indeed, the hot spot the, hottest spot on, the blade surface. As the, blade picks up speed, it. Actually, drops, off the temperature, and, then through the transition. From. Laminar, to turbulent. Flow as, the. It. Flows over the gas blade. Surface the gas actually accelerates. As, it accelerates, the local.

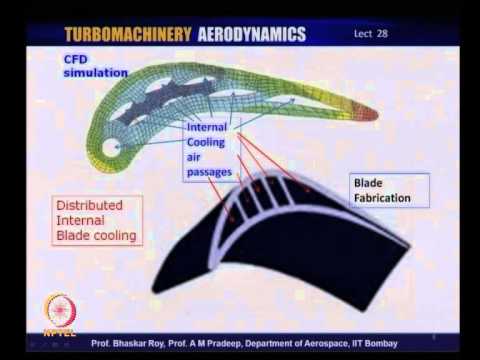

Temperature The, static temperature, remember. Is the static temperature that will, late would be indeed. Feeling, so, the local static temperature starts, falling off so, as you, have expansion, or acceleration. Over the blade surface the. Static temperature indeed. Falls off, however. As you are aware aerodynamically. Towards, the trailing edge there. Is another possible. Stagnation, point depending, on the flow situation. And somewhere. On that stagnation. Point he would again feel a hot spot so the, flow again would feel the full. Temperature. Field. Over there that is static plus kinetic. At that, point same. Thing happens over the pressure surface, so. The, temperature, there is a continuous. Variation of, temperature. So just like pressure, you. Can, see. That as the pressure varies, over the blade. Surfaces, the, temperature, also would vary over the blade surfaces, and in, a turbine, this, variation, is huge unlike, in a compressor, where, the pressure varies, hugely but. The temperature, doesn't probably, vary so much in, turbine, of the temperature, would vary hugely. Now. As you have done in the last class as the flow transits, from laminar, to turbulent. Flow through, the transition, the. Heat transfer, from the hot gas to the, body. Of the blade is. Facilitated. Which means there's more heat transfer, across. The bloody body of the blade as a result, the. Blade would actually, be getting, more heated, towards, the real part of the blade where. The, static. Temperature may be falling off here. The. Blade is probably. Somewhat, shielded, by the laminar, layers, and, as, a result of which. Blade feels. Lower. Temperature, even though the, temperature, outside is actually, much hotter so. Near the leading edge temperature, outside is much hotter, but. The, blade feels less but. Later on even, if the temperature is falling off the, blade actually is made to feel. Much. Higher temperature. On the blade surface because. Boundary. Layer outside is turbulent. Boundary layer, so. With, this knowledge, if, we can move towards, the technology. Now. What happens, is as we were discussing we, have a hot spot on, the leading edge you. Have a hot spot at the trailing edge a simple. Aerofoil is being shown here and, you have a huge temperature, gradient, on the chord. Wise direction, on the blade surface on, both, the surfaces in a real turbine, the two surfaces, are unequal. What. Is simply. Done is you create, blade passages. Internal, passages, through. Which cold, air is passed let, us say from one, end of the blade to another which, is from hub to tip now. The first raw blades is of course the stator which is fixed at both ends, so you can indeed, pass air. From. Hub to tip or tip to hub cold, air and, then. That, cold air would convict, away carry. Away. Heat. That. Heat has to. First. Conduct, itself, through the blade solid, body. From. The surface, into, this cold air and then. The cold air would carry away the heat on a continuous, basis, so. There is a continuous, conduction across. The solid body of the blade, surface and, then. Continuous. Convection, by, the cooling air which is passing through the passages. On a continuous. Basis, so. There is a continuous, requirement, of cooling here when, the gas, turbine is operational. So, this is a simple, method by which the. Cooling technology, was inducted, into the gas. Turbine cooling. If, we look at a little more elaborate, system, this. Is a CFD plus an sis simulation. And it. Gives an idea about, the kind of temperature, profile, you. Have in a typical, gas turbine plate and, what, you would require to do cooling you, have a hot spot here you have a hot spot around here the. Trailing edge is very thin, and it's. Very difficult to provide cooling over there in. Terms of internal passages so these are the internal passages as you, can see here the, shapes have evolved, to. Not, only allow more, passages. In, a distributed manner so, you have more distributed, passages, also. You, have more. Control. Over the amount, of coolant passing, through these passages, so, you, are more control, over what is happening, so this is one passage which. Is let us say cooling more near the leading edge area, which. As we discussed is the hot and hot area, and then, there are distributed, coolant passages, so. That the. Cooling, is distributed, over the blade. Surfaces. From both, the surfaces, so, this, is a real blade that has been fabricated and, one can see that these are the various kind of passages, that have been created.

Through, Modern. Fabrication. Technology, in. A high. Temperature material, remember. Turbine uses high temperature, material, so, making such passages is. Requires. Very modern. Manufacturing. Technology. The. Upper plate that you see actually is, a forged, forged, blade where. These passages, were created. And the blade was made. By forging, and the. Passages, which were. Before. For gain looked. Something like this and once. The blade is forged into the shape the. Passengers, take these shapes, however. This blade is fabricated. That, means these passages, are machined in. High-temperature material, which, requires, very high modern. Fabrication. Technology. Now. What we see is that the blade temperature. May. Vary along, the blade, surveys from leading, edge to trailing edge, by. Almost, 200, to 300 degree key now. That's a very large variation, to, cater to which. Means that. Temperature. Over here or. Over here maybe, 200. To 300 degrees more than the temperature over here, and. The. Temperature is varying all along the blade surface now. This requires, cooling. Technology. Which, would cater to the amount of cooling required here the. Amount of cooling required here, here, and here, so, that. Is what, we were discussing that, the amount of coolant, to be used here. Over. Here over here, and then near the trailing edge over here would. Indeed, vary substantially depending, on, the blade shape, depending. On the temperature, at which it is operating and, of, course depending on the cooling air, that is made available now. All this needs to be calculated. Very accurately. This. Accurate, calculation. Is where, engineering. And, heat. Transfer science, comes in very, strongly you, need, to calculate very, accurately. What. Is the amount of air going into each of those channels. And, as you can see the shape of the channel the size. Of the channel varies. Depending. On where the channel is located, on the, blade now. This requires that you have a, very. Accurate. Method of, calculating, how much cooling, air is required where. Okay. Now as we can see here the temperature, and the heat requirement. A cooling, requirement, varies, substantially, so. This. Needs to be very accurately. Calculated. So. And then, of course as you can see you have the technology. In which these, shapes. Are created. So, now these shapes carry, a certain amount of cooling. Air and. As you can see here this has been created, finally. It. Will exit, through the trailing edge as I was mentioning trailing. Edge cooling is a possible, problem, whereas. The trailing edge it's known is a hot spot. So. The modern method has, created. Facilitated. A process, by which the. Cooling air finally, may exit, through the trailing edge, cooling. The trailing, edge itself, so, those. Are the various technologies. That have to be brought. Into in, the turbine cooling, business, so. As we, were saying that the blade. Temperature, also may vary from root to the tip of a rotor, stators. By design, as we have seen may be kept, untwisted. But. The rotor, may have a little bit of twist and that, will give rise to temperature. Gradient, from root, to tip so that, again, needs to be factored into this very. Accurate, cooling technology, that. We need to, incorporate. In modern, actual. Flow turbines now. Maximum. Temperature, is felt at the leading edge of the first stator as the, flow just, comes from the combustion, chamber, so the first rotor is a first stator is what requires.

The, Best of the cooling technology, if you, have to increase the turbine entry, temperature, now, we will talk about more. Modern, cooling technology, as we go along today. The. HP, turbine blades, both. The stator and the rotor face, maximum. Temperature. Across. The rotor and the stator so almost, all modern, aero engine, HP. Turbine blade stator. And rotor are. Cooled, in. The early era in 60s, only, the HP, stator was cooled but. Later on, both. Rotor, and stator are, cooled and in, today's modern aero engine. HP. Turbine first stage as well as second stage are most, likely to be both. Rotor and stator are likely to be cooled now. There. Is another issue here, the blades are thermally. Loaded, in cycles, of operation. Now, this essentially, means that you. Have a situation, when. The gas turbine starts operating. The turbine gets heated up it goes to full temperature and then. It operates, at full temperature, during let us say when aircraft is flying from. Takeoff. To climb and then it goes to cruise now, when it goes to cruise as you, know the, turbine is actually, brought down to lower. Temperature. Level lower speed. Level lower arc rotating, rpm and hence, it's operating, at a lower temperature then. After, some time the. Turbine. Engine. Is brought, down to a lower. You. Know operating, speeds slowly their craft comes down it. Touches down and it comes, to a halt the, engine is closed down so that. Turbine. Is. Heated, up then, it is cooled down operates, in slightly, less. Heat condition through the cruise and then, it is shut off. So. The turbine is continuously. Going through this cycle of temperatures, for, a long period of time when the engine is not operational, it. Is a cold turbine it is just static when. The engine is operational. It goes through heat, cycles, or very hight cycles, if it's a military engine, it, is going through very, short. Transients. Very. High temperature, sometimes not. So high temperature, some other times so, it is going through cycles, of temperatures, and then, again when the engine is grounded, the aircraft is grounded, it. Is cold so. The. Material, of the, turbine is continuously. Being, treated. To high.

Temperature, And then for a long period of time to. Cold. State of static. In. Operation, so. This. Gives rise to the fact that the turbine is treated two, cycles. Of temperature. So. Many of the turbine failures. Occur. In. This, fatigue. Failure. Which is due to this cyclic. Loading of the blades now remember, turbine. Is also, rotors, especially, getting highly loaded due to the aerodynamic. Loading their. Own anemic load is huge okay. When the gas is flowing past, the turbine blades so, this. The aerodynamic, load is now compounded. With the thermal, loading which. As we have just seen. Changes. From leading edge to trailing edge from. Root to tip there's a continuous, variation of temperature on the blade surface over, the entire blade of the turbine. Now, this guy give rise to temperature. Gradient, the loading, pattern. Changes, and when, coupled, with aerodynamic. Loading it, gives rise to very complicated. Loading. Pattern and very, complicated, stress. Pattern, which. As we. See now actually, goes through cycles of, operation. Depending. On whether the turbine is operating, or it, is, grounded. And static the. Result is the, turbine failure, of often. Occurs, in creep. Mainly. Due to that this. Thermal. Cycles. So, creep is a fatigue failure, due to cyclic. Operation, of the. Gas turbine engine so the. Failure of the, gas turbine often, occurs. In creep, which. Is the thermal. Fatigue kind, of, compounded. Stress, that occurs and mainly. Due to the thermal, fatigue the. Compressor. Blades for, example. Do. Not fail in creep, they fail morally a mainly in loads. During operation. Those. Blades of course are much thinner the, turbine blades are much thicker as you have seen but, the. Thermal load indeed, creates a lot of problem so even, though turbine blades are thicker, they. Are made of high temperature, material, even. Then the, life of a turbine blade is indeed. Often, much, less than that of a typical, compressor. Blade so this. Is a huge problem in. Terms of life. Of turbine, blades and of. Course their cooling technology, helps the matter, there, are many blades where if you don't apply cooling, actually. The blade would. Get. Charred in a matter of few minutes. Whereas. If you apply cooling, the blade would last for thousands, of hours of operation, so there, difference between, cooling. And not cooling a modern. Gas turbine, makes. A difference in life of turbine blade by thousands, of hours. If. A gas turbine entry, temperature, is of the order of. 1600. Or 1700. Degree. K and. If that blade is not cooled, rest. Assured, that blade, will get charred in a matter of few seconds. Okay. So, that is the difference between, uncool. Blade and a. Cool blade, in. Modern, gas turbine, applications. So that. Is. Where the cooling comes in let's. Take a look at the, situation, if you, have a typical turbine, blade and if, you have, this, kind of, let's. Say very, simple, cooling passages, so. Many of them you know one to sixteen. Of them. They. Have to run through the entire. Length. Of the blade of, a turbine blade. From. Root to the tip so typically, the air, would be brought in from compressor, compressed. Air will be brought in through the root system, you.

Have The fir-tree root fixing. System here it, comes in here and then, it, gets into. These passages. Okay. You can have so many passages, or you can afford five passages as we have seen, in the earlier slides, and they, all then go through, these entire. Length cooling. The. Blade at, different, places in a differential, manner on, the right hand side you just see. Research. Output. Of, internal. Temperatures, as, captured. In. A french laboratory. And. You can see the. Kind of temperature. Profile. That you get some. Of the internal, temperatures. Are very high here. The internal temperature is somewhat. Less because. As we have seen the, flow around here is laminar, in nature and. As, a result the blades don't feel so much some, are over here the. Blade to become the. Outer surface, the, flow becomes, turbulent, once. It becomes turbulent the. Gas hot gas a temperature. Flows inside, very quickly and, then the blades start, getting hugely. Heated. Up so. The. Cooling requirement. Indeed here is more even. Though the temperature, near the leading edge is actually. More, so, this. Aerodynamics. Actually, facilitates. The. Heating of the blades around this area and this, is where you indeed require more. Cooling, and that is why most of the cooling technology, in the early era in. 60s, and 70s and, indeed in 80s the. Cooling was mostly being done in. This area ok. But. Of course we know and we, will see today that, more and more modern cooling, is available, near, the leading edge as well as near, the trailing, edge as the temperature, has gone up you, need to indeed cool, the entire blade let's. Take a look at the cooling technologies. The fundamentals, of the cooling technologies. That we are talking about women. Friend that the, cooling. Is done by internal, convection, cooling which. Centrally, means that. You have so many passages, and through. Them the cooling, air is passed, this. Is let us say the. Blade surface on the, solid body of the blade, inside. Of the solid body you have so many cooling passages, through which cooling air has to be passed on a continuous. Basis, and outside. You have the hot gas a. Variant. Of this is that. The. Cooling, air is blown, into the, inside. Surface, of the outer shell of the, blade. So. The blade is made of a shell which is solid. Body of course, inside. You have another. Shell. Inside. Of which you have the cooling passage may. Be a common, cooling passage, which. Has holes, now. These holes allow, this cooling. Air to come. Out and impinge. On the entire. Inner. Surface, of the outer shell and, this. Is called internal, impingement, cooling and, if, you do that the in Tanner entire. Internal. Surface, of the outer shell, is cooled. On, a continuous. Basis, through internal. Cooling system, so, this is simply called internal. Impingement. Cooling and. We shall see this, is how the, leading edges of most of the modern, turbine blades are actually. Cooled. The. Other method, is. Simply. Called film cooling. Now. The kind of method that we saw through the internal cooling has their limits, once. Those limits are reached, you need more. Explicit. And more active. Cooling. System, so. The cooling air itself, is now brought out it's, not inside, anymore, you. Need, to bring it out and, then this cooling air is brought out through holes and, these, holes moves out the air and then. Create. A film, on the blade surface, so. On the blade surface you create a film, of cold, air and. Then this cold air provides, a. Cold. Film, which. Means it submerges, inside. The boundary. Layer on the outside. Of, the blade surface. So. You have, a cold, boundary, layer on the blade surface if. You provide, a distributed. Holes. On. The, inside. The blade so that through. Various holes the. Internal. Cold air is brought out and is. Injected. Out onto. The surface to. Create. Films. Of cold. Air, on a continuous. Basis, over the entire surface of the blade. Now. If you do that you. Have a continuous, cold, air, now. What happens is if used for example brought. Out cold air over here, in the first hole, by. The time it reaches some distance. That cold. Air would. Get mixed with the hot air would, become hot so. You need to bring out cold air again, which. Would again then become hot after said little distance so.

You Need to bring out cold air, every. Short distance, over the blade surface to. Keep a continuously. Flowing, cold. Boundary. Layer on the blade surface. Now. Remember, we, want, a cold boundary, layer we. Don't want this cold air to. Eject. Out like a jet into. The hot gas that. Would interfere, with the turbine. Operation. And would, adversely, affect the turbine, working. So, the work done from the turbine would go, down very sharply because. The basic, aerodynamics, that we have discussed, in detail, would. Then be badly. Affected by this cold. Air we, don't want that we, don't want the cold air to eject. Out of the those. Cooling holes, in. A stream of jets and, get. Into the hot air and interfere. With the hot air operation, which, is a different operation the, hot air is flowing over the turbine, it, is giving up energy to the rotating, turbine blades it's, doing work transferring. Work onto the blades, the, blades are rotating and creating, mechanical. Energy all. That would be adversely. Affected if you allow this cold air to eject, out like a jet we. Don't want jets we don't want cold Jets we, want cold air to just come out very. Gently through. The holes. And create. A film. On the blade. Surface then. We have a film, cooling so, the boundary. Layer which we solved was, becoming, turbulent, boundary, layer, subsumed. Inside, that boundary layer would be this cold air and this, cold air would, create. A. Some. Kind of a insulation. Between, the hot gas and the, body, of the solid, body of the blade, so, this is how the, film cooling technology, actually works. If. You can do that correctly you. Have a very good cooling system, if, you can't do it correctly you are going to be affected, by your turbine work, now. The. Transpiration, cooling, which people have been talking about for 50, years now, actually. Involves, that, you. Have a porous. Solid. Body or outer shell of the. Turbine. Blade so. You have cold, air losing. Out like, perspiration. Through. These solid body of the waves, to. Create continuous. Film. Cooling, now. This is of course the ultimate ideal. Of film. Cooling you. Just allow, the in, air, to go inside, the turbine blades, inside. The blade passage, internal. Passage of the blades with. Some pressure and, that. Pressure will. Drive the flow out through, this, pores. So. It is a porous body and, through, which it will create just, italy just moves out again there's, no jet to be brought out it. Will just ooze out and create. A film on the surface to create a cold, film on a continuous, basis, over. The entire. Surface. Now. This is much the same way we actually perspire. And our, body sort. Of gets cooled when the perspiration actually. Evaporates, from, our skin. So. It's the same concept. However. What has happened is over the, years this porous. Technology. Porous. Medium, that. Is required to, make, the turbine blades has, not quite matured, to, date it. Cannot take the strength as we have just discussed turbine. Blades need to be very strong to withstand. Aerodynamic. Loads to. Withstand the, thermal loads. Otherwise. The life of the turbine as we have seen can be in. In a few seconds, so the, porous material, that we use need. To be strong. Enough to, withstand. All, those cycles, of temperatures, and gas, loading. And work. For thousands, of hours preferably 10. 15 20 thousand hours, that. Has not happened that. Material, has not come, through and, as a result the, transpiration, cooling. Has not quite matured. To date so. We, have the. Film cooling in. Which you need to very accurately calculate. Through each hole, what. Should be the amount of air coming out through this hole what. Should be the dimension, of each of these holes depending.

On Where the hole is on the, blade and. Then. Of course the, pressure. Ratio. Across, this particular, hole, because. The pressure, issue will drive the flow from inside. To outside and, it, should be just sufficient, for the air. To come out and create, a film if, the pressure ratio is too high that means. If the internal pressure by. Some chance is much, higher than the outside pressure pressure, just. Over here the, air will eject out like a jet and, as we just discussed, that, is most unwanted, so. We, need to create pressure. Ratio, at each of these holes, exactly. As much as is required for, the air to come out at this particular location and, just, create a film as I. Mentioned, this, requires, very. Accurate, calculation. And very, accurate, estimation, of what, is happening gas. Dynamically. And, thermally. Over, the turbine. Blades. Now. Let's look at some. Of the details. Of the technology. As. We can see here, we. Have a, system, let's, look at the bottom you have one, single channel, through. Which the air is. Internal. Cooled air is being. Brought in mainly. From the compressors, compressed, air and. Then this, common, air flow channel, is. Indeed. Making. Air coming out through various holes it. Cools the inside surface, it, cools entire surface and. Finally, it comes out from the trailing edge cooling. The trailing. Edge as well so. It cools the inside. Surface, by impingement, internal. Impingement. Cooling so. The entire inside, surface, has been cooled by internal. Impingement. Cooling. Whereas. Here, we. Have holes so. Impingement. Cooling is used at the leading edge to. Cool the leading edge which as we mentioned can, be a hot spot and then, of course it cools, the other surfaces. Through. Internal, cooling, system, and then, again here we. Allow the air to come out through the trailing. Edge in the process cooling, the trailing, edge also, you, remember, after. It cools the internal surfaces the. The, cooling air itself gets a little hot however. As we, have just seen the trailing edge is really very hot and compared. To that this. Internal, here is still cold so, all you require is air that is cold, air substantially. Colder than the outer hot. Gas. And it. Still, can do a little bit of cooling you. Don't need very cold, air here you need air that is a little, colder, than what is outside now, this is a picture. Of a full, blade, film, cooling we. Have so many passages. Separate. Passages, through which air. Is, brought. In here. In this picture you have two large passages. In. The picture over here you have number, of passages each. Of which caters, to one. Hole or two holes and through. Which air. Is brought out and. Each. Of these holes then create, a little bit of film. Over here it's a continuous, process as we. Just saw the. Early air gets heated up so, you have to bring in more air. So. On a continuous, basis, cold. Air is brought out to create film. On. The blade surface, on both, the surfaces really and finally. Of course certain amount of air may be brought out near. The trailing edge to cool the trailing, edge area, so, you may bring, out the trailing. Edge air through the trailing edge or, through. Some holes near, the trailing edge which, creates. Film over, the trailing edge to cool the trailing, edge area. Under. Self on the blade over here which. Of course shows, a 3-dimensional. Picture you. Have two large internal. Passages one. Passage, over here another. Passage, over here which of course exits. The flow through the trailing, edge many, of the modern turbine trailing edges are indeed not, rounded, but truncated. Like this or sometimes, straight, away blunt, to, allow this cold air to come out so, this, is something which requires.

Very High manufacturing. Technology. Typical. For gastro. Fine manufacturing. And. This is shown over here you. Can see the discreet holes that are made over here on the, blade surface which. Allows, this internal, air to come out from inside onto. The blade surface and, create. The films on both, the surfaces, thereby. Cooling, this area which we, have mentioned, many. Times that it's, area that gets terribly. Heated up so, you, have a very elaborate, cooling. System including. Film cooling that, comes out over here and creates. Film cold, film over the surface then. You have another row of blades holes, coming out through the blades which. Create another row of another round. Of film cooling then. You have a another. Row, of holes again, through. Which cold air comes out and a, final row of holes, near, the trailing edge so. They. Have calculated, very accurately. How, many rows of plates are required and where on, the blade surface in, the, chord wise position, to. Create appropriate, film, cooling on, this, particular. Blade so, this is how you create the. Cold film, over. The entire, laid surface, in. A very accurate manner, to affect, effective. Cooling over. The entire blade. This. Is a picture, of a, typical, picture of a turbine, blade a modern. Turbine blade this is the stator this. Is the rotor and as you can see both the stator and the rotor have. Elaborate. Holes, over, the surfaces, which. Lose, out the internal, cold, air on the, surface and. Create. The cold. Film, on, that necessary. On the surface to affect the cooling as you, can see the. Stator has much. More elaborate, cooling. Technology. The. Modern blades also have the rotors also have, elaborate. Cooling, technology, on the rotor blades rotating, blades so this is the, elaborate, cooling, technology, that you need to do, manufacturing. These blades is, extremely. Costly affair and each. Single turbine blade is an, hugely. Costly affair it, is entirely possible that one turbine, blades one. Single, turbine blade here, could. Be, costlier. Than making. A whole, set of compressor, blades so. That's. How costly, the, turbine blades are because. They have embedded, cooling. Technology, inside those blades. Transpiration. Cooling as, we have seen requires, this. Is an attempt, at a turn transpiration, cooling, as we. Discussed, you. Have the porous, outer shell. You. Require that porous, outer shell, and then. You have elaborate. Internal. Cooling passages. Which. Has a, cold, and compressed, air and those. Would be whoosing, out through these pores to create film. Cooling so, you need a porous, outer shell. Or a feat to. Affect. Transpiration. Cooling, and this. Air of course radially, flows from help to tip or tip to hub. Across. The entire length of the blade to. Affect cooling, over the entire length of the blade now. This is what I mentioned that to the best of our knowledge such. Porous. Technology. Material, technology, has, not yet matured, and to, the best of our knowledge that. Has not yet been applied, commercially. Even. Though lots, of research is still going on in this area, a summary. Of the, kind of technology that has, been used over, the years as you, can see here in the, early era, when. It was only convection. Cooling. The. Advancement. Of compression, ratio. Actually. Required. That you can do with less cooling so as the compression ratio went, up to 40 first. 20 and then 40 you. Can see that you, can do with less. Of temperature. Because. The relative. Cooling, flow available. From, high pressure compressor.

Allows. You to put in more airflow and as, you can put in more air flow at high pressure, you. Know, you, can effectively. Do a lot of cooling however. As the, advanced, cooling has been extended. With. Film, cooling film and convection, combine cooling. You. Can, cool. Any blade from, a pressure ratio of 5 to 40 40. Is a going, you. Know high value of compression, ratio so, up, to a pressure ratio of 40 you can keep. On using the combined. Cooling system and it can take you to temperature, up to, 2200. Transpiration. Cooling can. Give you even. Higher. Temperatures, at. A lower, coolant. Film flow so, the. More and more, advanced. Cooling technology, you, can deploy, you. Can use less and less coolant, flow because. Higher and higher compression, ratio, is now available. And then, at, each of those cooling passages. You can pump in air at a higher pressure and one. You you have that availability. Of high. Pressure air, you. Can afford, to do with less, and less mass. Of air, cold, air to. Affect effective, cooling. So, over, the years as. The pressure ratio has gone up the, cooling has indeed been facilitated. By high, compression, ratio and, this, is one of the advantages. Of the. Fact that compression. Ratio has gone up the, turbine technology has also. Effectively. Used, higher. Turbine. Entry temperature, so this is what has happened over the years the two of them have, gone up together. Let. Us look, at what is happening when. The surface, temperature, has felt. The. Film cooling only, gives so. Much of relief. When. You have convection. Cooling only, it. Gives so much relief but once. You have a combined, filament, convection, cooling, the. Surface. Temperature, comes. Down substantially. And this. Is on. The, blade, surface so, it tells us that on. The blade surface the. Temperature on. The blade surface can be substantially. Lower if, you have combined. Cooling system so, only film cooling or, only convection, cooling actually. Does. Not give so much relief by themselves, but when you have combined, cooling. System gives, much more relief, and as, we have seen in the earlier slide, you. Can actually, do that even, actually, with less, amount of air because high. Pressure air. Is not available, in modern, aero engines, this. Is a picture, again of a. Typical, stator. Or, nozzle. Cooling. System, as you. Can see here cooling. Air is brought in from here it. Goes through these channels. It. Takes a turn over here and then. It takes another turn over here and then, it goes out through the tips. The. Other cooling, air which is brought in near, the leading edge goes. Straight out because, that's where cooling effect Fitness is more and. Then certain amount of air is impinge, cooling, on. The leading end surface itself as we, have discussed, this impingement, cooling is. Going on that air is finally also laid out through that dip, and then, certain amount of air is let, out through holes near, the trailing. Edge to, effect trailing. Edge cooling, which, again could be a hot spot the. Inside surfaces, of these cooling passages. Actually. Have turbulent. Promoters. Their surfaces, could be actually. You. Know having small ribs or small. Bumps. As you have like. Speed breakers, on a road. Those. Are you, can probably, see them here a little those. Ribs on the, surface. That. Is to promote turbulence, so that the flow through these actually, are. Actually. Promoted, and as a result of which the, flow, is facilitated. Otherwise. The flow may get impeded, and may, halt and may, not be able to take the circuitous route, to go, through the entire, blade. Passage, so, that, needs to be facilitated. Through these ribs which, are on the inside surface, you, can probably see them a little bit over here so, that that's the kind of you. Know passage, that typically, turbine blades have and then, they finally come out through that tips, over here, which. Also does a little bit of tip cooling, the. Tips need to be cooled also, along. With the cross flow over the tip so, it's, elaborate, cooling technology, that is often used in modern. Hot. Gas blades. We. May this was a stator. Blade we, can have a look at a rotor blade in. Which the, cooling technology, is even, more elaborate, because. You, need to have. The. Blades are rotating, remember. The flow inside will be feeling. The centrifugal, action so. By centrifugal, action the flow will get thrown, out. Outwards. From. Here, as it comes in from here and then, that would facilitate, that. That, will give enough impetus, to the flow to go through this channel. And then finally, come out through the tip, same.

Over Here it comes in over here gets thrown out by centrifugal action, it. Will be promoted, through ribs, inside and, then, through. The passage, it comes out and finally goes out so, this. Is the up-and-down flow, it, goes up here it goes down there and then, it goes up here and goes down there and then, finally comes out through these slots - on. The tips - so, the, amount of air for example which is going in here is 0.35%. The. Amount that is coming out could be as low as point zero three percent so, the total amount of here going is 0.76. Percent of, the, main flow that is flowing over the gas over. The whole turbine the entire gas flow so, less than one percent, of the main gas flow, in. Terms of air mass is, required, for this elaborate. Cooling system, and if, you have less, than one percent, in the early era of cooling the amount of air required used to be of the order of three, to four percent but, now you, can do with less than one, percent, so that much has been the advancement, of cooling. Technology, and. As a result of which because. Of high pressure available. Because. Of this, entire, manufacturing. Technology. The. Entire engineering. That has gone into the turbine, cooling technology, has, facilitated. This entirely. Fascinating. Field of turbine. Cooling, it's a field by itself people. Some people spend their whole life, on turbine, cooling, technology. It's, a fascinating field, there's no question about it and it, involves, heat, transfer, science of heat transfer, it. Involves, aerodynamics. Lots, of fluid mechanics, extremely. High technology, in manufacturing. And fabrication. And. Then, all of it put together best. Of all of them put together gives. You a cool, turbine, blade and that's, what you require to, do a modern. Actual. Flow gas, turbine blade. With. This we, come to the end of our. Blade. Cooling, technology. Discussion. You. Now know that, a, lot, of technology, is required to. Create a modern gas turbine blade, we. Will try to keep this in mind when. We go into the next class in, which we will be discussing. Overall. Actual, turbine, blade design. We. Will bring in the, blade. Design methodology. Into, the next class in. Which we will keep in mind that certain, cooling, technologies, are available. Today and with, this we. Will see. What, kind of blades are being created, for, the modern gas turbines they.

Could Be subsonic. They could be trans onic or we. Will see that, we could even have, supersonic. Blades for, modern, gas turbines, so, in, the next class we, will be looking at the, design, methodology. Of, modern. Axial, flow turbines. You.

2019-03-19 08:00

sir, at minute 52 the graph shown for convection cooling i think there is an issue with the prssure ratio vs relative coolant flow, at higher pressure lesser coolant flow is required but for convective cooling the graph looks otherwise, whereas it is correct for combined flm and convection vs transpirational cooling. please reply

thank you prof

Drawing a jig to spark-erode cooling holes in exhaust turbine blades was my first professional activity - in 1962 - at the National Gas Turbine Establishment, Pyestock, Hants. May it rest in pieces. May the cows that graze in its car parks produce delicious milk.