I Fixed My CR250 Engine For $2!

In a, previous video you guys somebody put together the cr250, bottom end only, to have to split the cases once again because, of a missing washer so, I've got that washer on hand I'm, gonna install it and get, the rest of this bottom end back together I am super excited let's. Get started so let's, recap things a little bit when, I went to go spin the transmission, after I assembled, it I noticed. It would bind at some point so right there it's, coming to a bind and that. Led me to digging. Into the transmission and finding that missing washer so, it goes right underneath. This. Gear, the. Last gear on the counter shaft so. We have a washer on top the gear and then. There's a little spacer, in here so. That washer, was supposed, to sit right, underneath a spacer, and the, gear so they call that a thrust washer it's like a two dollar and fifty cent piece it's, crazy how such a small part can, cause so many issues so. The transmission was binding and then, it wouldn't want to shift in a neutral either alright let's go ahead and install this washer and make sure everything, is working properly, so most washers, are gonna have a, rounded. And a. Flat, face to it the. Rounded, face always, goes up. So. It looks like that's the correct washer, I'm. Gonna slide on the gear. Spacer. And the. Washer. Here. We go. Looks. Like it all fits on there good. Now. Let's, see if it binds at all. Man. That's that spins, pretty buttery, smooth, no. Signs of any binding, all right now to test to see if it goes into neutral so, I believe I'm in first gear here all the way at the end of the drum and. One. Click over, we'll be neutral. Right. There should be neutral and, how, to test this I'm gonna hold the main shaft and spin. The counter and they're. Gonna spin independently. Of each other so you, see. You'd, counter shop the spinning, but. I'm holding the main shaft so that is indeed, neutral, sweet, so, once again guys before you fully assemble, your transmission, make, sure you've got all the clips washers, gears, all that in place before. You put the cases together learn. From my mistake it is time to slap the left crankcase back on to the engine. Now. I've got the cases pressed together thanks, to this Tusk crank puller tool these, things are super handy to have and. Before I put any case bolts in I'm definitely, going to go through all the gears in the transmission, make sure it shifts smoothly and check. The shafts or any excessive, end play. Now. That is how it's supposed to spin right there super, smooth and there's no binding at all now, I'm gonna go through the gears and make sure everything, is in order all. The way down is gonna, be first, gear and then. Half way up is neutral, right, there as neutral, so. I'm holding the counter, shaft from, the other side and the output side and spinning. The main shaft you can see they. Are not spinning together so that's neutral. Alright. There is third. Fourth. And fifth. Now. That's a huge relief to know that everything, within the cases is good to go just got to pop those case bolts back in and then, I could start assembly the clutch and the, gear shift components. Now. Before I proceed any further this, excess, gasket, material is kind of bugging me so, I'm gonna shave it down with this little scalpel, flush. With the gasket surface. Okay. First up I'm gonna assemble the gear shift components, that go right here so, that will be everything, laid out here on the table and once, again just like the previous video, I've got the diagrams, printed, out and these, are a huge help before see how everything goes together and make, a treat got all the little bits and pieces so, thanks to this nihilo concepts, engine stand I can get the engine app pretty much any angle I need so, it's gonna make the most sense in this position, here I'll, have a good angle at getting all these pieces into place the, first piece that needs to go on is going to be the tensioner, for the shift drum so, that's gonna include the, tensioner, arm looks, like the spring a washer. And the. Retaining bolt, see. If I can find this stuff here, here's. The arm. I've. Got spring. The. Bolt is gonna have a little, edge on it or a shoulder. And. That. Looks like the washer, so. When looking at this diagram looks, like the spring goes on first in, that position and then. We have a washer. In between and in. Order for the washer to stick to the little stud I'm gonna put a dab of grease on there. That, should keep it in place. And. Let's. See here, looks like there's. A little notch on the. Tensioner. Arm that. Is gonna hook up with the spring. It's. Gonna go just like that. To, be honest it's actually gonna be easier to install that texture with. The end, piece off of the ship drum and that's, usually how I install them anyways but, I just have this piece on here from the get-go I'm, gonna go ahead and pull that off and that should make my life a little easier.

They're. Not a huge deal to pull this thing off might as well do it right all, right so we got the spring. The. Washer. Get. This arm into, its. Position. Sure, everything's lines up here. There. We go and. I'm gonna put a little bit of Loctite on the shoulder bolt just got some. Blue medium, strength there. And. As. I'm tightening down this retaining bolt here got, to make sure that shoulder it's within, the arm so. There's kind of legal things around and that will allow, that. Shoulder to go into place and the torque should be around six or seven foot-pounds on that one now the spindle, can go back on and you definitely want to put Loctite, on this bolt as well. With. This piece you definitely got to make sure that groove, lines, up with the pin on the, shift drum so. Kind of line it up before you set it down and. Then. Just spin it around until it locks into place, so. Right there it's locked in and. Then the bolt can go back in. All, right so basically what this tensioner, does is it keeps the bike in the gear so. You can see as I spin, the, shift drum, it. Is gonna walk into each. Of those details. So. I'll see the notches where, that roller or that tensioner, roller sits. It. Locks right into there and that, keeps the bike in the gear so, right now we're in first and I'll show you kind. Of how the neutral, setup, works I'll, bump it up halfway it's. Like you're shifting up halfway and that. Little half. Detent. There, that. Is neutral right there and there's. A detent, for each of the five gears and neutral. It's. Going to torque the center bolt to 16 foot-pounds and, then. I'll be ready to, install. All the pieces here, on the inside. Now. For this part there's a lot of little pieces to the puzzle so, I'm gonna refer the diagram and make sure I've got everything here should. Have two, Springs. Two. Poles, two. Pins. This. Little, washer. Or spacer, and the, center piece that all this stuff goes in so just to keep everything together I'm, gonna put a little bit of assembly lube, inside. This, piece it. Always helps with assembly, too, so. First thing goes, a spring. Side. Of each hole. And. Then. A pin goes on top of that. And. Then, to top it off goes, this, little pole they call it so. The slotted. Side that goes in. You. Can see there's a right and a left Paul, this one is installed correctly because, the slot lines. Up with a pin and then if. I took the other one try. To line that one up you. Can see the slot would be off so, that goes on the other side I'm, gonna hold this Paul down with one hand, come. Over to the other side. Kind. Of make it a mess with this, assembly. Lube but it's part of it, get. The spring in there grab. The pin put, that on top. And. The. Paul, goes. On top, of that. So. That's what it looks like all put together, now. Before I slide the whole setup into, the shift drum, doesn't. Hurt to put a little bit of assembly lube in there. So. Before this piece goes into the shift drum I'll, have to slide the, retaining, plate on top of it. It's. Gotta be super careful going in not. To knock those poles, and, pins. Out of that, part. There and then once again these, bolts will need some Loctite. And. Then the last piece for the shifting assembly is the shift shaft this. Just goes right through the hole that goes through both of the cases, make. Sure there's a washer, on here, right. Here that washer most. Bikes will have that. Looks. Like I'm gonna have to spin this piece around a little bit for it to line up. Well. Unfortunately I'm. Gonna have to flip this thing around, I had it together wrong. There. We go that fits a little better before, I tighten down these bolts I'm gonna check to see if the shaft lines up and, it's. Gonna need a little, bit of Lube here for, where it goes through that seal on the other side. Yep. Looking, good. All. Right I'm gonna pop the shifter on to the other side of the engine and make, sure all. The shifting, stuff is working properly. All. Right I'm gonna show you guys exactly how, this works when you shift the bike I'm, gonna figure out what gear I'm in right now. Should. Be in first. All. Right spinning the shaft. I'm gonna go up into neutral. It's. Neutral right there now. That I've got the gear shift assembly out of the way it is on to installing, the kickstart shaft and just, like the transmission I've, got a diagram printed out here and this, time I'm actually gonna go through and check each individual.

Washer And clip not, gonna mess it up this time so, starting, at the very end here looks like we've got a spring and. Then. A looks. Like a gear with splines. In the center this. Part right here another. Circlip, and a washer, see. A washer, and obviously a circlip, then. The, main gear. That's. Obviously in place and, then, on the other side there, supposed to be a washer. Here. Take. A look see if we got that I. Do. Not see the washer there. Yeah. So number 10 right here supposed. To be a washer on this side of the gear and it, is missing see, if I can dig that one up somewhere, thankfully. I had a bunch of random hardware from this engine got it in a bag with the bike and I. Found the washer, inside of there so that'll, work out perfect. Slides. Right onto, the shaft and looks. Like it's a good fit so like, I mentioned earlier it, definitely pays to check all your washers, and clips I'm not sure what kind of effect that would have had missing, this washer but. You know what the diagram shows you got have it on there and then pass that washer we've got shaft a little. Collar this, part right here and then. The main recoil. Spring and also, there. Is another gear. That goes on the, counter shaft and, it. Looks like there's sleeve. Behind, it as well we, go find that sleeve actually. It's right here so. That's sleeve make sure it fits on to the gear, yep. It's. All good so time to assemble the kickstart, shaft onto the engine. One. Thing I need to mention with this kickstart shaft is this piece on the end needs, to go on in a certain position there's. A little dot right here a little. Locating, mark and that. Needs to be lined up with the dot on the shaft as well. Go. Ahead and. Get. Those lined up like, right a bit out there. So. Having this piece lined up it's pretty critical because, it does set the tension here on the spring and, aligns. The, stopper, tab in the correct position as well just, like installing any other part especially one this high up on the engine definitely. Want to put, some assembly Lube inside. Some, of these areas and. Then. To install the kickstart shaft this tab that I mentioned earlier needs. To go behind the, stopper, plate so. To slide it in until, it. Is right, above the stopper plate and, then. Rotate, it behind. You. Get the spring on the other side. So. Right, there that's, where it should be. And. Then. For the mainspring here you got to make sure the sleeve right inside of here is over. The. Tab, that goes into the shaft I'll, show you a better angle here so you got to have this sleeve around the tab on the spring that protrudes, down into the shaft looks. Like this together correctly, it's. Gonna set some tension, here on the spring and line. Up this tab with, this, hole on the crank case. Just. Like that. Make. Sure it's all settled. All. Right we're good to go for that part and then just below the kickstart shaft is the transmission counter shaft and this, is where the kickstart, idler gear goes, onto I've.

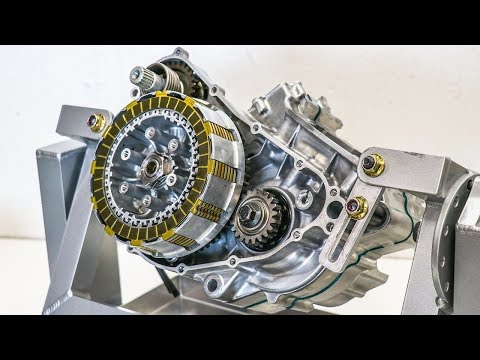

Got A little sleeve on and. Put some more assembly, Lube and, then. The idler gear slides. Onto here. So. This idler gear is what transfers power from the kickstart shaft to the clutch basket which. Is attached, to this shaft and that eventually makes its way to, the crank shaft there's, one last little thing before I start to assemble the clutch the, crank primary, gear, to go on so. That is gonna be these four pieces right here we've got the bolt a washer, the, gear itself and a sleeve that goes behind it so. I've got all that right here. And. Whenever. You're installing a gear onto a shaft you want to make sure there's no markings here on the gear or the, end of the shaft that usually indicates that things need to be lined up but, with this one I don't see any markings so it's good to go it, can be put on in any position. I'm. Just gonna leave this bolt loose for now since it's easier to set the torque once I have the clutch altogether but, don't let me forget that one guys if. You guys are enjoying the videos make sure you support the channel of a shopping, over at Prime MX com I've got hats t-shirts. Stickers, and, a few of the supplies used throughout the videos over there as well I'll put the link as the first one down, below. For. The clutch there's a lot of pieces to it so I need to check this stuff over starting. From the shaft it looks like we've got a spacer. And a. Needle bearing. Spacers. Right here, needle. Bearing. Clutch. Basket there's. A washer that goes in between. Should. Be this one right here the thicker one, clutch. Inner hub so. The basket, here the. Inner clutch hub and. The. Push. Rod or. The rod that goes through the center that's, what activates the, clutch and then. The whole plate set that is soaking in oil let, me zoom in here we've, got, another. Washer. This. One right here. The. Tab, that goes underneath, the nut that, is a like, a locking, tab so. This one, right here this, is the old one tough. You always want to replace those so I've got the new one right here. And. Then the. Nut. That, holds everything together and, that. Nut is right. Here shoot. This thing is pretty beat up should, almost replace it I'm, going to dig through my parts bin and see if I can find one of those, so. When you see this right here where the diagram has they can cut away that'll. Be like a different design or in, this case a different order of the parts so, you definitely want to make sure you've got it together correctly so. For this one I'll have to go look at the. Diagram, online to figure out which one is the correct order all right I'm over here on Rocky Mountains diagram, and how I'm gonna differentiate, the, order, here is we've. Got looks, like a 19 to 20 and then, a 24, and a 25, so. I'm gonna scroll down look. At all the part numbers here so it looks like we've got a 19, out of 20 and no. 24. And 25, so. That would indicate that, the. Design for this bike needs to be the 19 and 25 so. Washer, first followed. Up with, the. Locking tab or the locking plate and then, continuing, on down the line looks like we've got the, lifter piece a bearing. A washer. And the clip so, that's all pretty much one piece and that, is this, part right here and then. Finally, on top the clutch is the clutch pressure plate all. The clutch springs and the clutch bolts so. I've got new clutch Springs right here and there. Should be, five.

Clutch, Bolts so. It looks like everything, is here time, to start, assembling the clutch so just like the diagram shows I've got the spacer, and the needle bearing up first and, I'm just gonna coat everything, in this, assembly lube. And. Then, next up is this washer that goes in between the basket, and the inner hub and there's, a rounded, face or a rounded, edge and a flat edge if. You run your finger along the edge you'll be able to feel the difference there so, the round edge is gonna be facing out I can't. Forget a little loop here. And. Then. Next comes the clutch inner hub. So. I've got the washer this. Retaining, clip it just goes on like that with the tabs locking. Around, the. Hub, here make. Sure that's locked in and I was able to find an identical nut off of a CRF 450 that parted out but it's in a lot better shape than the old one so that, worked out perfect I really, should have just gone out and bought a new nut for this but. You know what got. To work with what you got now, the easiest, way to torque the center nut for the clutch is going to be to use a clutch, holder tool so. I've got this tool from Rocky Mountain just. Grabs on to the. Clutch hub like, so, so. I'll show you how this works in a second I'll be torquing that nut 259. Foot-pounds, now, I'm just gonna clamp, this tool on to the inner hub but. Definitely, not gonna put too much pressure on it don't want to damage that hub. Set. The torque wrench to 59, foot-pounds, and then. I'll be all ready to torque. Now. This is actually the first time I've ever used one of these clutch shoulder tools didn't. Damage the hub at all and it gave me some great leverage to torque down the nut so, I would definitely recommend grab, it in one of these from Rocky Mountain now the whole purpose of this locking washer is to bend the tabs onto the nut that, way there is no possible, way this, nut can ever come loose I'm, gonna bend some of these tabs over using, some, pliers here. Okay. Now I've got the clutch plates ahead of me so I've had these friction plates soaking in oil overnight just, in this Maxima, MTL oil since. That is what I'll be using in this bike so. You're really only to soak the friction plates the steel plates do not need to be soaked although. It's a good idea to have oil on them upon installation and, the clutch kit I'm using is this tusk setup that Rocky Mountain sent over so big big thank you to those guys for providing, this kit so all the friction plates on this bike are the same they've. All got this, little notch here on looks. Like, three. Of the tabs so. I'm gonna line all those up here in the basket, it's. Gonna reposition the stand a little bit before I start sliding these in. There. We go. So. The first one. Goes. In it, doesn't matter. Whether. It's you know which way it's facing they're all the same and. Now. For the steel plates so, there's a rounded, edge and a. Flat, edge on each plate if, you run your finger along the edge you'll be able to notice the difference so, I've always ran the plates with the rounded edge facing, out and I did some research I noticed a lot of people are saying run. The plates with, a smooth, or the rounded edge facing, in so I'm gonna try it on this one with the rounded edge facing, in but, honestly I've never noticed a difference, with, the rounded edge facing, out it might just be me but I'm. Gonna give it a shot for this build. So. Just gonna alternate, steel and friction, steel friction and then. Lining, up these notches in, the, basket as well. Alright, guys that's it for the clutch plates gonna move on to installing the rod and the. Lifter piece that goes on the end followed, up with the pressure plate so here's the push rod this runs through the center of the engine and connects, to the clutch cable on the other side so. It's the same on either end doesn't matter which way it goes in just. Gonna. Lube up everything super good with this assembly, Lube. Then. Of course we've got the clutch pressure plate. Followed. Up with some. New clutch, springs these, are from Rocky Mountains tusk. Is the brand. So. I just found out I'm missing, one of these bolts on the old hub there was a bolt snapped off in it and that's why I replaced it so, I'm gonna have to dig through the parts bin once again and see, if I can locate one, of these clutch bolts right. On I found one from the same serie four could do that parted it out it's the same length and everything but.

It's A little bit different color but who's gonna know the difference. It's. Always a good idea to tighten these bolts down, in an even consistent. Pattern I. Kind. Of want to do like a star pattern or just, alternate, every one. Now. The torque spec on these is seven, foot pounds so, I'm gonna tighten it in the same fashion as I, did earlier. Sweet. That is it for the clutch I am completely, done with it oh and, I almost forgot I still need a torque the crank primary, gear bolt to 47, foot-pounds, and. How I'm gonna do this is by, taking a rag and. Stuffing, it in between the clutch gear and the, crank gear, just. Like that and with. That I should have all the levers needed to torque this bolt down and another, thing you can actually do here is put, a penny in between the gear as well or I. Think motion Pro makes a gear. Holder tool so. It's like a little gear jammer that you put in there as well but. We'll see how the Reg trick, works. So. It seems like that worked out all right just as long as I can get this rag out of here now. All. Right cool, so I'm gonna call this side the engine done for now it's gonna flip it around and install, the flywheel, and stator. This. Crank doesn't have the Woodruff key or the locating, key for the flywheel installed yet so, I'm gonna steal the one off the old crank looks like it's in pretty good shape. Now. For installing the stator and the flywheel, it's, pretty straightforward the. Stator just uses two bolts and before. I slide, this in I've, got to put the clutch actuator, arm into, the bearing first. And. Now for the flywheel the only thing you got to consider is lining. Up the keyway with. A Woodruff, key on the crank and. Then. This bike just uses a washer, and. A. Nut. And. I. Believe I should be able to use this clutch holder tool to, hold the flywheel in order to torque the nut down let's, give it a shot. And. This. Nut calls 440, foot-pounds. So. That's as far as I'm gonna get on the engine bill for today wish, I could show you guys the engine covers but that's gonna have to wait till the next video so, stay tuned for that man, they look so good can't wait to show you guys and once again this engine bill would not have been possible without rent rabbit sending over the rebuild kit which, included that crank bearings. Gaskets. Seals the. Engine stand was supplied, by Hilo concepts, best, wood out there I love that thing, the, transmission, polishing, was done by trick engineering super. Nice addition to have I cannot, wait to test that out and then. For the clutch components, Rocky, Mountain sent those over and. Then. Oil and, assembly. Lube that, was provided, by maxima, so, a big big THANK YOU to those companies for helping out so I'm gonna wrap up the video right here hope you guys enjoyed it if you did give it a big thumbs up and hit that, subscribe button down below as, well and I'll see you all in the, engine cover video keep. It pride my friends.

2018-06-13 03:50

fry em, buy boyesen ones. Prolly strip the boyesen ones to because the coating dont last worth a damn

cerakote them, bronze?

You had some blue powder on your ig story a while ago. What is that for?:)

Great job! Very informative and well explained.

Cameron Niemela You clean them up with Scotch-Brite pad

Did you make new ones from modified scotch brite pads? :D

Cameron Niemela cerakote bronze color

Anodize it, red or gold colour

Spray paint

I saw it on your instagram. hehehe

Cameron Niemela HRC REPLICA covers. Order them through Luckynino.

Bronze ceracoat, factory finish?

Cameron Niemela QUIT TEASING US!!!!!

boyesen!!

Cameron Niemela powder coat? Lol

Bronze cerakote

boyesen magnesium colour covers or scotch brite the oem ones, also a magnesium colour cerakote will look awesome, since you 've also other parts

Who else loved the bloopers at the end?

Don’t forget to lube the springs

Cameron is the best

Wonderful

Love the vids love the series! Keep it up!

This is some next level clickbait,well done!! haha

Oooh some one has a potty mouth! Good shit my friend. Lol

Looking good

nice video bro.

Man i love watching your videos even I'm past this stage of wondering what your doing... I just love your cleaning process everything looks brand new...i will clean most of my projects mainly the inside .. but damn you can really bring a bike back from the dead...i love it...keep them coming...I'm learning a lot...thanks

More bloopers pls n thx

Your the best person to go to for bike info on yt

Hey I have a vintage dirtbike and I’m scared to tear down the motor to clean the cases. Is there anyways I can clean them without taking the motor apart or getting water in the motor. Thanks!

love your videos keep it up Cam

Love the vids man! Keep up the great work❗️

will you ever do a supermoto build in the future ?

That'd be fun!

This bike would look so sick with all the modified stuff but still maintaining oem graphics and seat cover.

Why do you oil friction plates cam? I want to know

The oil needs to penetrate the friction plates in order for them to work properly

Loved it especially the end! Thanks for letting us know your human! Keep it up!

$2 plus $9.95 shipping. Am I right people

Your videos of two-strokes are what made me decide to buy the 125 in my videos! I owe you a beer for that!

I love your channel, I just want to know how did you learn how to do all this, did you go to school to be a mechanical engineer or something, because I’m very interested on how you know exactly what to do.

Thanks! I am mostly self taught, just went out a learned the ropes myself.

If ever in doubt about something, put assembly lube on it

everytime double check

This is one really cool video Cameron

Didnt file the basket where the clutch disc's ride? Makes shifting much smoother

So clean!!

It's always the simple little parts that make the biggest difference lol

Do you speak any finnish/puhutko yhtää suomee?

Thanks for this video, so fine !

proof of how the small things really makes THE difference!

Beauiful

I love the videos so informative of going through each step and pointing Out little things and mistakes keep it up.

you got so far on this engine, good job (:

Hello Cameron ! Ha voilà, verry nice gearbox ! Verry nice video ! Excellent week-end for you !

You look like Ron Howard's son

Cameron is type of guy that fuc*s with assembly lube.

17:55 High Sided Films forgot

Dope my guy

Buttery smooth with that assembly lube! Great job cam love your videos

Actually i believe the notches on the friction plates are for using the clutch holde tool

I use red loctite on primary gear bolt,, that's the only one bolt on dirt bike i use red loctite

Wouldn't be a good mechanic if u didnt swear a few times aha ,sick video anyway !

Droping bolts and stuff on the floor and have to walk around on your knees and look for it like 10 times per houer is a part of the game lol..

Is there a special way to read these assembly drawings?

You should definitely show all those mistakes ! I mean you did, but how many did you hid lol ? Great video, great bike, can't wait to see ya ridin' it !

I am so glad you misplaced that washer. I have been putting off throwing my 98 cr250 motor in for months now because i just couldnt figure out what was wrong. Just so happens it was having the same symptoms and now its only gonna cost $2 and a few days waiting to get it all back together. Really appreciate the Quality vids. Keep em coming brother!

Yo bro, put locktite on the flywheel nut! They always have locktight on it from the factory! I know this because I run a 10oz flywheel weight on my 07 CR....Besides that perfect job!

Great vid though

Anybody else get unsatisfied when he reopened the cases? Lol

Love this series, has helped me get to The point to do it myself. Would love a similar series with a 4-stroke.

What brand of torque wrench did you have there?

OCD on a clean workspace, Kudos! Nice series thanks

Can't wait for that first BRAAAAAP!

Most Excellent work.I believe that's the best engine assembly video I have ever seen.

What part of the transmission was polished? And why not just get a new part?

Everything was polished inside the cases. See this video for more https://www.youtube.com/watch?v=yYIBOVtX-yU

yessssss he's human!!!

Awesome video. Now I can get a bike super cheap w/bad crank. You made it very simple to follow.

Haha love the END of your video . I laughed so much

Whats that blue sticky substance you put under the blue gasket?

MORE BLOOPERS

That’s sick as f**k

Hi mate please can u tell me wherecyou got the engine stand

nihiloconcepts.com

Can’t wait till the next vid. Love ya videos man!

Great video dude!

My wish was granted!! Haha sick man! Cant wait to see it chirpn away

i am very excited too! why? ! cause usually engine builder or transmission builder speak in passing of the actuall issue! aqnd people are left scratching their head, what was the issue? a washer? speaking about it isnt seeing it ! awsome job !ty for taking the painstaking time to explain why up isnt down etc

87th.

Got to say it, one of you best videos yet! I appreciate how clean your work area and equipment is in the video. So many times I’ll watch “ others” videos and everything’s a mess. Hate that. Nice work!

Awesome job mate, been watching for a while an have been here to see all the CR 250 teardown and rebuild vids.

cool man!

The only video series I look out for

Another great video! Thanks!

love the longer videos

☝️

Awesome work dude, great vids.

another great well made informative video thanks Cameron can you get me a cheap OEM KTM 85 cylinder barrel?

Cameron Niemela I bought the bike for £700 and the cheapest full top end rebuild kit is between 480 and 700 gotta be a cheaper alternative?

Thanks! Sorry nothing like that in stock

hey pal, great work, but just for the sake of knowing,from one tech to the other they say its easier to slide the clutch steals on with the rounded edge in to prevent the sharp edge from possibly putting a burs in the hub .. as if some one is gonna beat them in crooked with there favorite B.F.H.. lol..

Cameron Niemela. How do you know so much about dirtbikes. When did you start working on motorcycles/dirt bikes???

Cameron Niemela I started a little younger. But most of my inspiration comes from these videos. They help a lot. Especially when I'm stuck on something

I started wrenching at 12

I love the end of this video!! Ha ha ha (B***H) Tell her who's boss.

Super excellent video Cameron. What camera uses, your quality videos is super full hd

Thanks! I use a Canon 80D

I want to see the video of the Hot Rod crank grenading.

Fesh af! Nice to see it sandwitched together

Was there a ballbearing inbetween the clutch actuator pin and hub?I did my engine and clutch seemed a bit short on the pin

I noticed you didnt mention anything about ignitiontiming on the stator might be usefull info :)

Can't wait to see the bike running

I love this half-hour video

Potty Mouth!

This is definitely my favorite bit of the 250 rebuild series to date *:)*

just the way the steel plates are stamped , does not matter what way they are facing

Banging out these videos. Good job on that engine. I bet you powder coated or cerakoted the covers.

This engine will run soo smooth love your videos

Damn fine job! I can’t imagine there are many bikes on this planet put together with so much love.

So clean

That engine looks awesome!! Like it belongs to Factory Honda.

buy the anodized red footpegs and levers from ebay your vids inspired me to fix the clutch on my sx☺☺

adjusting the TDC made the kick-start tougher harder to kick at the beginning and that's how I ate through my kick-start it started right up first kick

Excellent

Dude are you self taught or did you train to become such a meticulous bike mechanic? I used to mess with engines about 20yrs ago and wish use have taken it further as a living!!! Your work looks second to none, would be very interested if you answered my first question! P.s I cannot wait to see and hear this bike complete and running and of course you riding it around your mx track....talking about tracks how is your track coming along?? Loved the track build vidz also! Your living the (my) dream man! Keep them coming! Thanks....all the way from Wales UK

Thanks man! I am mostly self taught! Yeah can't wait to rip her around the track!!

the trick is not to mislay components in the first place.

Did you put that number 10 washer on the wrong side of that shaft, or does it matter?

keep making video bro!!!!! amazing work!

So I'm not supposed to have extra parts left over?

Isn’t there 6 gears?

we dont wanna go out and buy all these tools to rebuild an engine. show us tricks without using tools

awesome video!

Ha. Loved the bloopers. Hey have you ever thought about doing a detailed video on the front shocks (leaky seals or general maintenance)...I run a Honda 2012 crf 250r so I’m loving all this knowledge bud. Thanks for all the hard work.

Love the videos, Cameron! SOO GLAD you showed Rocky Mountain MC's blueprint-database. I am rebuilding the transmission on my 1993 KX250 and it's been invaluable. Greetings from Finland :D

START IT UP

I never take the shifter paws out of the side to aggravating

hello what's the red oil?? where i can buy it??

Glad the washer fairy came!

Very helpful vids bro!

Love his videos, but dude can really drag on a bike build...

Can you get a video of you taking apart where the kick-start is on your your CR125 honda

The engine you bought each and every part of you? So let me ask you to buy at the wep page so that you address sin sister home brother thank you

Man you cost me a lot of money. I went out and bought a project 250, locked up bottom end, just so I could rebuild it! Four stroke so not exactly the same rebuild.

Can anyone tell me if a 2017 Crf 450r Engine can fit on a 2002 modle?

This dude has every single tool in existence. “Here I’m gonna pull out my clutch holder tool.” If I tried rebuilding my bike it would be a nightmare

I struggle with my gear. It's hard to change from 5 to 1. It kind stuck then I have to insist until it works.

Hi Cameron, it seems so easy to do mechanic when watching your videos. I enjoy watching your footages, it reminds me when I was doing meccanos toys. But everything which seems that easy needs a lot of practice! congrats for the videos, really interesting

To sad you put a crappy hot rod in, otherwise great build.

the crankcase bolts weren´t torqued.....

You mentioned a previous video on this engine. In the future can you please put a link to all videos related to that topic? Diagnosis, tear down, cleaning and reassembly. Thanks.

Rebuilding my bike but when I take the engine cases off I can go through every gear, slap the cases back on and will only go into first and nuetral. What’s the problem?

Ahhhhhh it’s kinda like a puzzle

is that engine holder fits for 250f engine?

i cant stop watching ur videos they are so well made and so entertaining i love you

One thing I noticed that you did was wrong that shaft collar that you put in on the crank and it rides on the seal. I noticed it had a groove all the way around it.this ride on you crank seal. Rule of thumb is if you could feel it with your finger it needs to be replaced this is what blow s your crank seal and make your bike smoke really bad in your motor will not clean out. That shaft collar is a $44 part.

awesome videos in depth keep them up great stuff

Awesome you have a new subscriber here! You explain things really good!

what is the thing/part you hate most about assembling or dismantling a 2stroke engine?

Do you have family in Finland because you have finnins last name?

Nice

Haha the last outtakes are relateable

Awesome blooper reel dude :-D

nice vid but please less adds

is it nerdy that im watching this entire video even though I dont even have a cr250 :D

that washer looks like it was the one for the trans

Have you heard about alternati g each clutch fibers notch? Ive heard it helps aggitate/ scoop more oil for the clutches. Hmm. Kind of like rolling a star on the ground. Point to point to point to point. Instead of, whomp, whomp, whomp, whomp. Lol.. I'm a little crazy....

brilliant.did u go 2 school for all this .im putting a 1981 xl250 together and i find that difficult lol

Include Thai caption

This is the best Service/repair video that I have seen on youtube. I am subscribed and glad that I found your channel.

If it moves, assembly lube.

great video, this might be a stupid question (i'm no mechanic) is the bottom end of a 2 stroke the same as a 4 stroke?

Great videos mate, but now I have assembly lube stuck in my head

Made in Japan

109k subscribers 109k views

When you put the grease on the case how does that prevent the gasket from leaking?

where did you got these diagrams for rebuilding the engine?

You are so amazing brother Great job

Should be a teacher, love the videos man I learn quite a bit

Love you videos bro thanks for not editing the little mistakes !!!

Rounded side doesn't always go up. Rounded side always goes to non-moving part.

fake bullshit

Cameron - You do a terrific job putting these engines together. I, too, like to assemble my own.....then I pretty sure that it is done correctly. A lot of times I do it without a diagram but I won't do it anymore. You've certainly convinced me that using the diagrams makes it a lot easier. Clean and careful.....Quality is JOB 1! Ha! Stole that from FoMoCo.

Great demo Cameron, the devil is always in the details. Thanks for sharing this.

Man I love your work... Very nice criteria when it comes to making sure everything is spot on!! I just wished you didnt put the seals of the bearings before closing the crank cases in order to check the end float of the crankshaft and double check its alignment with the cases as well. other than this pretty damn good job lovee it keep it up!!!

Ah man

you should show how you got it apart that would of been interesting

What was that blue stuff on the gaskets?

I like how you show how to order parts. It is a learning process and need to double check which actual part is needed for the build. I know because I have ordered the wrong one or not all the parts needed

grease

Ausome video man!!!

I presume you are timing the stator later? Your attention to a clean background and good lighting make your video a pleasure to watch.

hahah the bloobers at the end x)

86 cr125 transmission the same

hello xin chào

I bet this guy puts loctite on his cock before putting on a condom and puts assembly lube on the condom.

This is exactly my problem only thing is my whole bike is re assembled

What did I do to the engine covers?