GPG Outbrief 09 - Next-Generation Chillers

Good. Morning everyone and thanks for being here and we'll, hope we'll, get one on when, we get to that portion of the presentation, before. We get started I want to go over a few logistics. Today's. Webinar is based on two GPG, assessments, they're variable speed magnetic, bearing or maglev chiller and the, variable speed screw chiller and both, the full, reports, as well as summary, findings and infographics are available, and, gsa.gov. And. Today's webinar is, based as one of a series the. February February webinar. Will be on plug load control, and it, will discuss, findings, from GP G's report, on advanced power strips as well as well as more recent developments, in the field of advanced power strips and smart outlets. In. March we'll be featuring the honeycomb solar thermal collector, and this, solar. Thermal collector, is particularly effective, for solar hot water systems. Without, a storage, tank. April's. Webinar, will discuss electrochromic. Windows, in, december GPG released two reports, of. Test. Bed assessments, of electrochromic, windows in general office space and highlighting. The effectiveness. Of these windows in glass curtain. Wall facades. Recordings. Of the webinars as. Well as an upcoming schedule. Is available, at gsa.gov flash, GPG. Today's. Webinar, as we've some of you have experienced, we've been participants, are muted and it. Will be in you'll be in listen-only mode but. You can submit questions using the chat box on the right side of your screen and you don't need to wait until the QA QA session that'll happen at the very end of the presentations, in fact we encourage you to submit questions throughout the presentation and. Now. Mike, Lowell, who's the GPG project, manager for the variable speed screw chiller assessment, will be facilitating. Today's webinar and, walking, through the agenda Mike. Thank. You Andre next slide. Here. The agenda for today's webinar. Which. One could a brief overview, a gbg, by the director program Kevin Powell. Kevin's. Opening remarks. We. Will transition, the technical, portion of webinar, with. That Kevin welcome. Next. Slide. Yes. Dick sides thank you very much. Yes. There I am. Crabbing. Ok. Next slide. Just, a couple of notes about, what. The, aims, of, the. Emerging technology, programs, at GSA, are and. Then. How this particular research, supports, that. The. They. There, are two programs that constitute. The emerging technologies, division, at GSA, the first is the. Proving, ground and this is a result of we're, actually presenting results a couple, of field trials from proving. Ground projects, and then. The the, intent of these proving ground project, is to provide real-world. Data, that. Validates. The, performance. Promising, technologies. Technologies. That do prove out and. You'll hear about two that have, proved, out are. Ones, that we, then are looking, to further, deploy. Across our portfolio in, order, to improve, its financial and environmental, performance. So. Next slide. Next. Slide yeah there we are so. The, I think the key thing and, what, I hope everybody will understand, on on this call is that, there really is, a lot, of investment, in. In. In really developing, next-generation building. Technologies. The. Challenge. For most of those technologies. Is, that in. The, real, world operating. Environment, of buildings, there's a, fundamentally. Conservative, impulse. To. Replace. Things with. The same things because you, know they work. The, plaint of the proving ground program is to take, out, some, of the risk of what. Essentially. The next-generation technology. Because. There's some concern does it actually deliver in the real world and you. Know our experience is sometimes. It does sometimes it, does with, you. Know certain types of caveats and sometimes it's really just simply not, ready for primetime so. That's what we try to do we try to bridge that it, shows on the slide the technology, valley, of death and. The. The, important, thing to understand, is that this, these. Results. Have enabled GSA, to make. Investments. In our buildings, even. In the fiscally. Constrained times. That. Are really, delivering. Real-world. Savings. So next slide. Our, process, is that every year we hold a. We. Publish, a request, for information that, actually has closed, in, December, the. Current one that is to say as. A, after. We receive. All of our submissions, we have independent. Subject, matter experts, score them we. Select. Series. Semi-finalists. Hear from those semi-finalists. Select. The best of the best pilot.

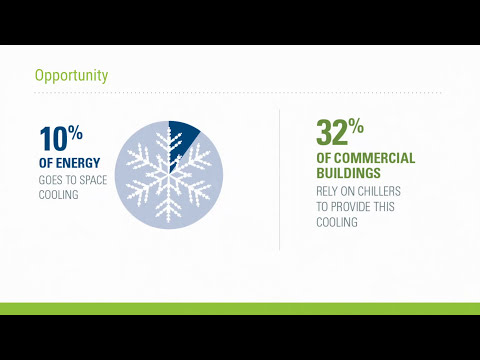

Those Within our portfolio. Partner. With Department, of Energy National Labs, who really are world. Renowned experts, in conducting, these kinds of field studies. See. How they how, they shake out and then. Those that, that. Actually deliver promising, results, we recommend those. For. Deployment. In. Our ports our, portfolio, and. Also to come, up with kind of, guidance that can help I should also say that the the results, from. Proving. Ground evaluations. Are intended. To, also. Facilitate, adoption. By private. Sector folks so that private and we've actually found that there's, a there's a fair amount of confidence, that these these outcomes. Generate. In the private sector for exact. Cleveland in the same way that that they do for us next, slide. And. With. That I'm going to turn. This over to Jeremy Jenks of Pacific. Northwest, National Lab. All. Righty thank, you Kevin. Yeah. I actually, operate. In. That kind of in that valley of death region. Working on thermally, driven, heat. And power cycles. Cooling. Cycles, so, a lot of experience. And that realm based. Off that slighted, killed earlier cabin next. Slide please. So. I'm, going to present some results, from a study that was conducted by. Staff here at P&L on a variable. Speed and magnetic, bearing chiller that. Was installed, side by side with a different. Unit we'll talk about at. A Federal. Building. And courthouse located. In Pine, Bluff Arkansas. Next. Slide please. So. In general just the, big picture, 10%. Roughly 10% of the energy, in. Offices. It goes, to. Its. Base crewing, and and. Of that 10%. 32%, of the commercial. Buildings. Are. Actually relying on chillers, to provide that space space. Cooling. Next. Slide please. So. GSA, is unique. In that 80%. Of, their their floor space is attributed to large build and, most. Of those buildings, are cooled, with water cooled, chillers, so. Looking. Into, applications. Or opportunities. To to reduce the. Power. Requirement. For a given cooling Lotus is certainly an advantage for. GSA. Next. Slide please. This. Is the cutaway view of a. Magnet. Variable-speed magnetic, bearing chiller you. Can kind, of look at all the different. Internal. Working parts there but. Speaking. In general the compressor, uses two, impellers, on a single, high speed rotating, shaft, which is actually, only moving, part in the compressor, and the. Two impellers provides two stages of compression, which provides, high efficiency, and, a fairly compact line.

The. Compressor has a fully integrated variable. Speed drives and this, allows, the compressor. Highly. Efficient, and certainly. Relatively, efficient compared, to the other. Children we'll talk about in a minute especially. At partial lows that's one of the unique things with, with this particular. Compressor. The, shaft with impellers is levitated, during rotation using digitally, controlled magnetic, bearings and unique. That. Unique feature reduces, the, friction heat, caused by conventional bearings. Adding. Again to the efficiency but. Also eliminates. The need for lubricating. Oil and. The ancillary equipment to go into, that lubricating, oil system, which. Reduces. The amount of overall maintenance requirements. So. Again yeah the compressor, is digitally controlled with. Microprocessors that, manage the compressor, operation, and provided. Self diagnostics. And correction, so. In a nutshell that is the mag. Bearing. Magnetic, bearing shield, compressor. The EC right there. Okay. Next slide please. So. This. Was this study was conducted. During. A. Fairly. Long cooling, season back in 2012, the study period was started. Earlier than anticipated I, believe it was in March and went, on through to September so it gave the, researchers. A good, opportunity to look at a, lot of different data, this. Particular. Building, is over a hundred thousand square square. Foot and it, has to. Each other is located, to 150. Each other is located, in the mechanical, room, so, what, occurred. Is one, of the chillers was due to be replaced it was a rotary, screw chiller and, it was replaced with this magnetic. Bearing. Chiller. That you can see that details. On the image on the right called variable, speed chiller 1 and, so. All the, both. Units were. Instrumented. To determine. The overall coefficient. Of performance and. Look at that. Throughout. The entire cooling season. Next. Slide please. Well. This other chiller, was a rotary, screw killer that was working, side by side with the, new magnetic. Bearing, chiller it. Was a it's a hundred fifty ton rotary screw chiller it was installed in 1993. And. If, it, really was before, there, was any variable, speed it was installed before there was any variable speed chillers and. These. Smaller, chillers. I think, more from a cost perspective than. Anything else needed. To be rotary. Screw, at. Anything below I think 100 anything. Below, two, two or three hundred tons the. Centrifugal. Chillers. Just really didn't exist. One. Thing to note is this. Is a side by side study, but, the, refrigerants. That were used were. Different, so the r22, the the. Rotary. Screw killer, was, using r22. Refrigerant, and the. Magnetic. Bearing chiller was using, r134a. Now, to just, do a quick. Look. At those two refrigerants, at standard. State points for HVAC. You'll. Find that at. Least from my back, of the envelope. Calculation. -. So. In, that sense, this study is somewhat conservative in the charts that are following. Look. If you look at the table on the right these are just comparing the two chillers the. Original, chiller they're, both 150, tonnes the only difference here is a new chiller obviously. Has the magnetic bearing, and there are two individual. Compressors, in that, particular unit the biggest thing that you can look at the oil tank heater up. There, is one of those for the original chiller not applicable. Or the new chiller because it doesn't require oil. And. You can see the difference in refrigerant, there. And at, the bottom of course oil is not applicable for, the new chiller, next. Slide please. This. Is showing. That, the. Overall, coefficient performance. Versus, the, chiller load for. Both of these units the. Gray line, is showing the old chiller, performance, the rotary screw chiller. And. Then the green. Is showing that the new chiller and it's really just a, lot, of data. That's. Kind, of hard it, may be difficult to see a trend but what. You can see looking. At the green data for the new chiller in that there's a an. Optimal, operating, point, when they when, they. Compressor. RPMs. Are, slowed. Down the. Compressor speed is slowed down and that, occurs between 27. And 33 percent of. Full. Load. So. We're actually seeing a theme, by reducing. By using this variable speed and increasing, efficiency and, given. That most, of the time the, children gonna be operating a part load that's a huge benefit, for this type of chiller, as.

For The old chiller, you can see it drops, off as. You reduce the, cooling. Load and. The reason for that is in these old, chillers. That didn't have variable speeds had to restrict, the refrigerant, flow in some manner and. Of course there's. Essentially, an, Associated, loss. Of work usable. Work associated. With that that, reduces, the overall coefficient. And the coefficient, performance, for those of you that may not be familiar is, not. An efficiency. It's. Just a measure of how. Much power or. How much cooling, we can. Get. Out of this unit. Versus. How much power we have to put. Into it. In. General. 42%. What. We found was 42 percent, energy savings. Because. Of this this, reduction, in, this increase, in coefficient performance as we reduce, the load there's, a 42 percent energy, savings from. One and, one chiller versus. The other shoulder. Okay. Next slide please. At. The end of the study period there, was a roughly. A. $9,000. Energy. Cost reduction, per year assuming. The. Energy. Or, the cost, of energy electricity. As shown there in the. Subtitle. Firm. It was very a lot of studies that P&L had conducted previously, for a Navy program textile the. Payback, period is strongly dependent on the installation cost but. In general. Throughout. Most of those studies it was found to be less than five years, for. This particular, technology. Next. Slide please. Operation, maintenance I spoke to this a little bit earlier, but clearly, some of the benefits, it's smaller and lighter then, similar. Capacity. Compressors. It's. Quiet, because it's because, of the mag magnetic, bearings it's frictionless. So. It can be played you know these. Especially. For new spaces they need chillers can be placed next to ox fence spaces, and, of. Course it's as, we saw it's more efficient, cooling at lower, you. Get more efficient coming at lower partial loads as. You reduce the speed. Of these centrifugal. Chillers. Next. Slide. Alright. I'll hand it off to one. If he I, don't know if he's available or not. Yeah. Yeah yeah. One Griego is a regional energy engineer, for gsa region seven and, he's now going to provide insights the region's embassy deployment, and operations, thanks. Ron take it over, thank. You Kevin thank you Mike, good. Morning everyone I'm.

It's. An RFA honor honor, for me to be here, and talking. About our, experiences. With the deployment and operations, of these mag bearing chillers. Next, slide. Since. The. Release. Of the, gbg reports. On the mag Marion chiller technology, GSA. Is seeing an uptick in the. Deployment. Of the mag bear and chillier technology. Overall. GSA, has deployed 210. Of these nightmare and chillers, region. 7. At. The region we have installed. 68. Of them with. Four pending, next. Slides. So, the 68 mag Marion chillers represents, a little, more a little more, than a third of our. Region. 7 chiller inventory. The. Range of sizes of our mag baron shows range from, 60. Tons one compressor, to, 750. Ton for compressor, units. About. 90%. Of these magneri and chillers are water cooled with. The remaining being air-cooled. Now. What makes the, Magnar. And chilled attractive, is their. Low IPL. V values. Which. Are in kilowatts. Per ton as. You can see the mag Marion chillers the. Values for these madmen shows range from point three to 0.35, which. Are lower, in. Comparison to, what you see for. Rotary. Screw screw, or centrifugal. Chillers, a. Little, explanation on the IPL v. IPL. V stands for integrated Partlow. Value, it. Is the, it. Measures. The overall, average efficiency. Of a chilled, cooling system. So. Basically in. A nutshell the, lower IPL, B value will, look being more efficient, your chiller. Next. Slide please. Next. Slide. Thank, you so much thank, you. Lessons. Learned from being, incorporates. In these night variant shoulders these. Mega bear shows need to be operated, differently since. Since. With. This technology, you maximize, your energy efficiency at, lower, partial. Loads. Which. Means. That, a few. Things one that, the onand contractor, needs. To be properly trained to operate and maintain these, chillers. And. So. We've. Incorporated. That requirement, on, in. Our scopes of work when we conduct. These children. Projects. The. Other thing that's the, other thing that we have. Learned. From going through these shoulder placement projects is that. Because. Of the energy savings, of. Going. With these mag bearing chillers that. Depending. On the territory. In which you're replacing. These chillers, that. Whether. It's whether. It's with an encore, or center points or energy or whichever. Area in, those cases. These. Chiller. Replacement projects, are incentive, eligible, so. So. Main. They're. Driven off of lower, IP le values, when you're replaced in Chile with a mag Marin chiller and as we've already, shown the. IPL. You guys are lower or Magda. Ranchos was compared to. Rotary. Screw, or centrifugal, chillers, and another. Requirement is that they have to be a h RI certified. Give. You a quick, example, we. Were. In the process of receiving, incentive, money from, entering, were. We, we had a six hundred thousand dollar project where we had incorporated magma, and chillers over. At, both. The a bear and tail, bogs federal, facilities, down to Orleans. It. Was a six hundred thousand dollar project and one, the process of receiving. Sixty. Thousand dollars and, incentive. Funding from entering. So. This helps for two reasons one it, receiving. Infinite money helps in terms of shortening your payback and then. Secondly, we can, deposit, the sixty thousand, into, which, we normally do when we. When. We receive.

Incentives, Toward. The. 863, money which, we then use toward. Future, energy projects, so. It's sort of a win-win. Sort. Of a win-win for GSA, there, unfortunately. It took us a while to understand. That. If. There are incentive programs out there for chill, replacements. So. But. We are getting up to speed on on, that. On. That. Requirement. Next. Slide please and, actually the last two slides are going to be case studies. This, one. Involves. The Fort Worth federal center billing, twenty-three. Back. In April 2015, we, had, installed. We had replaced two chillers with. Mag. Bearing chillers both water-cooled. 150. Ton, two. Compressor. Now. These, now the training data that you see. Represents. The elects the month by month little, electrical, consumption for, the entire complex, not for the equipment. Nevertheless. As, you can see since we install. These cnidarian, chillers that. We saw a, 30%. Almost a 30% drop in our logic in our electrical consumption and that's why 16 from FY 15. Which. Equated to a, reduction. Of almost two million kilowatt hours we. Also saw an electrical, utility, reduction, of. One. Hundred and twenty six thousand, dollars or, about twenty. Eight percent cost. Reduction. Partially. Due to the nightmare. And children ology. This. Was the best, case scenario the, next slide will show the. Worst case scenario. This. Was, the. Pickle, farm very complex, in Austin Texas, where. The project was handled, at the service center level. They. Had, replaced. The 600 ton trained chiller with a 440. Ton mag, bearing chiller. Installed. Back in December, of 2013. With. A. Little. Or no. Input. From, our, regional, headquarters and, as. You can see, we. Actually saw, in many cases, a natural, slight, increase, in our vegetable consumption and. When. We, when. I later took part in a, an internal. Audit for the awesome service center back in 2015. When we talked when we spoke with the owner and contractor we. Found out that we found out that the O&M contractor was, actually operating, nine barren shows on full load just. As that they were operating. A centrifugal. Or screw, chiller and so. They. Weren't provided, the training on, how they're properly, operates.

These, Mag there and chillers and so we had to make arrangements for, that train to occur. And. So. Those. Are the two takeaways, from, from. This particular case, study for pricklethorns every I. Think. That is it on my hand I. Think. I'm going to pass it on to Michael for our next presenter. Thank. You. Thank. You Vaughn. Next. We have Dan Hallett dan is an orangy staff member at Oak Ridge National Laboratory. His, focus is on emerging technologies that. Serve commercial, industrial facilities. And Dan's, the primary investigator for, the variable speed screw chiller Dan. It's, up. To you. Okay. Well good morning everybody on next slide please. This. Evaluation occurred, at the Cindy 8 building, in Washington, DC in, 2015. And 16 the. Building had recently been renovated and, the chiller plant was about to undergo a major overhaul, replacing. Two Overson, terrifical chillers as part. Of this overhaul, GSA, chose to install a 275. Ton, variable. Speed screw chiller in parallel, with. A 275. Tonne magnetic, bearing centripetal, chiller the, magnetic bearing chiller is of the same type evaluated. In the previous GSA, study and is widely accepted by the agency, both. Units will be connected, to the same chilled water in condenser water loops the. Configuration. Allowed GSA, to evaluate, their performance and, their near-identical operating. Conditions, next. Slide please. The. Original report from this evaluation, was issued in December 2016. In February. 2017. The, manufacturer. Of the magnetic bearing chiller Dyken, and the, compressor, dan Foss raised. Concerns, about aspects, of the report as a, research, organization Oak, Ridge National Lab, welcomes, fair scrutiny and, GSA, was through the report and commissioned additional, internal and third-party reviews, after. Six months of review three, major points emerged, number. One the report substance, and overall conclusions, are unchanged. Number. Two language, within the report was edited, to clarify points, being misinterpreted. Also. Documentation. Has been added to better characterize the study as a whole, number. Three at the suggestion of the National Renewable Energy Laboratory the. Third-party reviewer, shown, performance, data was an alliance with a second method commonly, used in energy savings, performance contracts. This, alternative, analysis, corroborated. The reports initial, findings. Details. Of the review process are captured in a 14 page preface, that was added to the reissued, report, overall. The report grew from 32, to 66. Pages with. The added documentation. Next. Slide please. There. Are two key design features which distinguish, the variable speed screw chiller first. The compressors, are of a positive displacement design. This. Allows the unit to rapidly, respond, to the changing cooler requirements, found in reelabilities. Second. Coin, capacity, is controlled, by simply, changing the motor speed, these. Two features eliminate, the requirements, for mechanical, unloaders, found on centrifugal, compressors, and older. Rotary screw machines, without. Those unloaders, their inherent inefficiencies have, been removed from the refrigeration, cycle, thereby. Increasing, the chillers performance, in the dynamic hold of actual buildings next. Slide please. Here. Are pictures of the tea machine in the mechanical, ring of the X building, they, were connected in parallel to, the same chilled and condenser, water loops during. The test the maintenance staff operated, the units on a day on day off schedule for the most part the. Team kept track of the condenser water temperatures, and percent, full load such that as, much as possible under, field conditions the. Unit spent the same amount of time under, the same conditions, next. Slide please. Instantaneous. Data was collected in 5-minute intervals key, performance parameters, for the energy consumption rate measured, in kilowatts, per tonne and the, percent full load at which the chiller was operating, the. Team chose to measure performance, instantaneously. As opposed, to averaging, over a five minute interval so, we can truly capture, how performance varied, under dynamic field conditions, using. Average 5-minute values would have resulted in neither curves rather than the broader scatterplots, this performance, very enslaved and lost, with.

Each Chillers data set a second-order, polynomial was, cur fit to the data these. Curves are shown on, the graph I would. Like to clarify a point of possible, confusion between this graph and the graph showed in the previous evaluation. Of the magnetic bearing chiller in, the previous study the, chillers performance, curve rose asn't, went into a part load condition, whereas. In this study the curve lowers as low decreases, this. Is because the previous graph measured, the coefficient, of performance in. Which a high curve indicates better performance, graph. In this study measures, the energy consumption, rate in kilowatts, per tonne in, which better performance, is shown by a lower curve it's, the same outcome, showing, shown, using two different metrics, a weighted. Average was applied to the curves in order to compare each units performance, at. The X building the variable speed screw chillers energy consumption, rate was 11% lower than the magnetic bearing chiller it. Must be noted that performance, at other sites under other conditions can vary, therefore. The reports final recommendation, is that both chi'lan types can. Show comparable, energy usage and should, be considered by facility. Owners, next. Slide please. As. Mentioned. Earlier the, National Renewable Energy Laboratory recommended. That the data be parsed in a second method in, which the energy consumed by each chiller, in a given hour was, compared to the average outside, air temperature during, that hour this. Method is used in energy savings, performance contracts. When, a contractor, wants to compare the performance of two chillers before, and after, a retrofit. These. Graphs capture, that data and, further separate, them based upon the condenser entering water temperature, they. Show that across the units operating, spectrum, the variable speed screw chiller consume less electricity, and magnetic, variant, children, the, exception, is at the right of these graphs when the outside air temperature a condenser, entering water temperature, were both warmer, at, this, point the magnetic varying chiller started consuming less energy than the variable speed screw unit.

Overall. The average Airy energy consumption indicated, by this analysis, method, corroborated. On, the previous slide next. Slide please. One. Performance, claim from the variable speed screw vendor is that their design could easily handle swings and convention, water temperature, that, were outside, the design parameters, at, the 8th building, design. Temperatures, were 65, to 85 degrees Fahrenheit, for, both chillers, in. March. Of 2016, there, was a stretch of sunny warm days when air conditioning was required that, the cooling tower Basin was at 55, degrees Fahrenheit, the. Variable speed screw chiller handle bestowed up without any issues when. The magnetic bearing chiller bender was contacted, it, recommended, not starting a unit until the condenser water loop had reached 65, degrees Fahrenheit, this. Cold water condition, could occur at other sites during shoulder, months or during a time when a tower base when a towers Basin heater failed, during. A hot spell in the summer of 2016 we. Had the opportunity, to test the opposite condition, the. Operating staff allowed the condenser operating, the condenser, entering water temperature, to rise to 95, degrees Fahrenheit this. Test replicated, the condition that might be found at the cooling tower fan were to fail or, if a multi-cell, cooling tower were to completely lose one or more cells due to maintenance or other conditions, the. Magnetic bearing chiller tripped off at its preset, high limits the, variable speed screw unit operating, continuously up, to 95 degrees Fahrenheit without. Any issues as part. Of discussions with the magnetic bearing chiller vendors they, stated that their units could be built to handle any condenser, water range found at a site the. Operating, parameters would simply have to be stated up front in the specification. Next. Slide please. Historically. Screw chillers have a reputation for being too loud my. Old boss from the early 90s refused to specify, screw units for that very reason, below. Is the manufacturer, provided data that shows the sound levels across each each, units, range of operation, as, you can see they are very similar and is and you've already heard testimony, about the quietness of the magnetic bearing chiller, so. The 8th building mechanical room, did not allow for artistic, think I can tell you anecdotally that, it was very easy to carry on the conversation in, the ring even, near the chillers the, no indias part of the room was near the pump batteries, next. Slide please. This. Light shows some direct comparisons, from the manufacturer's, literature, the. Variable speed screw chiller has one 200 Sony pots and compressor, the, magnetic, Marine chiller is built on a 400 centering and asked to 210. Compressors, even. Though the specified, cooling capacity, for both units was, 275. Tons, during. The evaluation, the. Oakridge and GSA, team had, extensive email conversations. With the equipment rep near Washington, DC who. Is supplying two magnetic bearing chiller the. 400 timeframe was questioned, but. Their rep repeatedly, stated that the configuration was selected, as it was quote the most efficient, to meet the 275. Ton requirements, the, complete email chain is included, in the final reports, the. Two chillers have similar external, dimensions, but a variable speed screw, unit is heavier. The. Variable speed screw, vendor, gives, us a budget price of a hundred nineteen, thousand dollars for their children, while, the NBC, unit was purchased, for one hundred and eighty five thousand, dollars through normal GSA procurement, channels both. Prizes included, similar packages, and startup support, the. Budget price for the variable speed screw unit seemed unusually, low so, a third party was used to go shop the vendor the, price was confirmed, through this process, next. Slide please. This. Test wasn't previously which, focused, on the magnetic bearing chiller indicate. That both technologies. Offer performance that is substantially, better than a standard, water cold chiller as, defined by the federal energy management program, a, facility's. HVAC, needs will best be served at facility, management and the design team consider, both chillers, when looking at purchasing, new water-cooled, units the, needs of the specific site must, be weighed against, rates of individual, chillers, next.

Slide Please. Next. We had feedback from the facility, operation, team at the H building, we. Receiving a feedback from Kenny Thompson he's the gsa property, manager and she could tell by the hat in the photo a rabid. Dallas Cowboys fan, we're. Serving with him are. Then. Stewart and Randy Burgess or te LR our joint, venture the, Yates building podium contractor. Anyhow. Let you and the team take it over. Everybody. Just. Give a couple of things. That. Ken and, Kari. You chose and I think they both work great but I'm, gonna turn it over to the two experts. This. Is Glen Stewart and Randy Burgess. The, via the, VFS runs, mourne mourne. Season, and it, does accept lower. Temperatures, when we Randy the carrier the, carrier which started about 50 degrees but. The Dyken. Would. Not start under 65, degrees and, after. Hearing. From dike and they're saying that they can build that differently. For different areas, and, that. Being said has you see in the picture the, cooling tower Basin is about. 25, to 30 feet in the ground with, no heaters so. We, have no way of heating up our condenser. Water during. Start-up on cool mornings so. Different. Setups may. Lend. Better, for. The Dyken than, our setup I guess, is what I would say to that. I. Would. Say that the, carrier chiller. Is. A little noisier at low loads attends a surge a little bit but. Both chillers, are very, good within noise levels, so. I would, I would, say that that both chillers have their positives, and you. Know they have their challenges to. Do. We have another slide here or. Yes. We're here now here's where it shows how how do you go down into the sump of the UH of. The cooling tower so, a little different I don't know if anybody else would see that out there except for for, what we have here. And. Yeah. The screens the, screens that you see are actually the intake for. The air and then, where you saw on the top of the brick towers that's where the outlet, is and the. Hole is have you access, to go down to clean it or. Check. The pumps or something of that nature so. But. In the end in the end we give we give both. We. Get we get we get both chillers a thumbs up. In. Our, actual. Daily. Work. With both of them and just. That just add on one that we have Garrett carrier actually takes care of our carrier chiller and I can take care of our Dyke and chiller and both. Of them have given us excellent service and we plan on using both of them in the future. Do. You have anything. Great. Thanks. Guys and. Next we'll have Dan how it will talk about best practices, Dan. Well. Welcome back we're, going to go through a few thoughts that should be considered when looking at a new chiller. In. Both evaluations. Of the magnetic bearing in the variable speed screw chiller focus, was entirely on the chiller, that. Piece of equipment is but one of several that make up the chilled water system there. Are pumps cooling, towers a piping, system and. Controls that oversee everything, perhaps. Circumstances, of such that a heat exchanger, can be added to allow free cooling also. In September, 2016. The. GSA proving ground published an evaluation, of a chiller control, optimization. System that might be right for your site it. Is important, that a qualified, mechanical, engineer to a thorough technical and economic analysis. To determine the right combination, of equipment, to control us to serve your facility, and and. As assistance, being installed perform, proper commissioning, to make sure all equipment, is working correctly in. Concert, with each other at your. Peak was the, h project, having autumn listed deserves mention, hey. The, original chillers at the site were to 350. Tons and terrifical units, reflexively. The design team was steering towards in sewing units of similar capacity, only. After performing, a heat gain loss calculation, did. They learned that the building use had changed, such that 275, 10 years would, be much more appropriate, next. Slide please. Okay, oh yeah that is the correct food as, mentioned earlier the magnetic bearing chiller was more sensitive to. Condenser water supply temperatures. You. Know I'm gonna see the slide here I. Do. The work profile, yeah. Yeah, I think the. Mistake is to make the. Key point to make here is that as you're working with you as you're looking at your building pay. Attention to the profile, that that building operates, that as. You can see and instead of blow comes, straight from me if I should provided, data as you. Can see as. The. Load profile, changes, the. Kilowatts, per ton for each type of unit will, shift whereas.

At A hundred percent load, the. Variable speed screw unit has a slightly higher kilowatt, per ton rating, we're. Down at fifty percent load it starts to go a little bit lower if. You have a building that operates. Consistently. At a very high load, rate such as perhaps a data center that can, skew your results one, way or another or if you have a building that operates a lot across. A wide spectrum with. The large amount of time at, low load or mid loads that. Could skew your decision. In another direction it's, important, to pay attention to your load profile, when selecting, a chiller next, slide please. As. Mentioned. Earlier the magnetic bearing chiller was more sensitive to condense your water supply temperatures. That were outside its design operating, range if. You have a site that is likely to experience, wide, swings in, condenser, water temperature, or, one where a chiller trip would be costly, such as a data center be, sure to clearly specify the full range of temperatures, that the chiller might experience at your site the. Evaluation, at the eighth's building did not measure any Marshall cost might be associated with the, magnetic very children with a wide range of condenser, temperatures, but, these must be evaluated. Specified. And balanced, with the site's actual requirements, next, slide please. In. Areas. Which have unusually, high electric demand charges, it might be viable to install a thermal storage system, or, some other met of shifting the peak tune into off-hours and, finally. All children's need maintenance, different. Manufacturers, have different maintenance presences. In various parts of the country the. Same can be said for the variance of item contractors. Who operate facilities, their. Comfort level with different chiller brands and technologies, can vary make. Sure that you'll have access to the maintenance resources. When selecting, your brand of chiller Mike. That wraps up my portion back to you. Thanks. Sam and, now we'll enter into our QA. Thank. You. Switch. Screen here. And. Let's. See first off Zach asked, if I could June continuing. Education credits would be offered for this training and the answer is yes. You. Need to complete a survey to. Receive the credit and you can reach out to Michael Hopson, of GSA. Let's. See. Scott. Chalmers, ask. The question, I think JJ this will be for you aren't there also accelerometers. And capacitors, for. The NBC chiller, as well. JJ. Is that the case guys. I'm, not sure on that one I. Had. To look into the Google, drawings and see where those would be located I wouldn't. Be surprised. Okay. And then JJ, would you have any ideas, to the. Required. Maintenance for, the MBC. Yeah. I think there's another question coming up on that that. I think, one, might answer, but in general, I'm, not sure exactly what the manufacturer, requires, but. As we talked about earlier the variable speed oil. Free. Centripetal chiller with magnetic bearings, results, may, result in lower maintenance costs. As a result of elimination, of the compressors, oil system. Take. A look at actual. Requirements. Okay. Squit has to turn down on the maglev. Quote. Unquote he says I have heard 10%, I, see. JJ doesn't know if. Someone else knows please let us know and and shat. The answer and we'll try to pick that up. I. Think. The answer the. Cost, answer, was covered, so, I'm going to ask a question about the cost between the two and that was answered in Dan's presentation. And. Then Dave asked how did the payback for the NBC and DSS compare to pay back compared, to a modern, centripetal. Dan. Or JJ I don't know if you have any thoughts on that. Yeah. Mike this is dan we're. Looking at the payback, for, these chillers. There. Are so many factors, that go into calculating, the payback your, utility rates your operating, profile, how. Many hours per year do you do. You operate. That. Is so heavily dependent on the individual, site data set to try to give a you.

Know Chiller, a has a you. Know 3-year simple payback compared, to chiller be anything, that, I, would. Say to, that effect. Would. Not be valid at any, given site so it's you, know to get back to one of the points that was made near the end of the presentation. Each site has to really be scrutinized. Based. On its own individual, characteristics. Okay. Thanks. And. Keith, has just the noise of the NBC and the higher or, lower octave, band and as Dan's, presentation, showed, both. Shelters the NBC the DSS operated, that 70 to 80 decibel. Range. He's. Also asked what kind of compressor warranty does manufacturer. Provide and. JJ. Didn't have any idea I, don't know one. If you have an answer to that by chance given your, elaboration. Of NBC's, in your region. And. Yes I'm I don't. Have, I don't have. That information offhand. But I I can, research that and provide that okay. Thanks. Hey. Mike this is Dan. Yes. I had a comment on the issue of manufacturer's, warranty. I'm, prior to joining the lab I spent about two years and they specifying. Design, engineer, and. My experience, if a buyer wants. A certain warranty, you, know a certain period. Manufacturers. Are open to negotiating, those again. Site. By site based on what the buyer wants, what would be in their best interest. Talk, to each manufacturer, and. Figure. Out what would best serve the individual sites needs. Okay. Thanks. Bob, asks do they have chillers that are external, style air-cooled. Choice, yeah so you answered the chat but why don't you wouldn't take that for the rest of us. Yeah. I just, looked I was just looking online and yes they do have, direct. Air-cooled. Chillers. For. I guess, is. He's, speaking about MV. NBC's. Very. If. It's for NBC the answer is yes they do yes as, a matter of fact I think as Juan mentioned. Region. 7 has several. Air-cooled, NBC. Chillers. Tim. Asks, how. Many manufacturers. Offer the NBC's and, do all major, manufacturers, offer them and. JJ. I'll let you in just a second but wonder again they've got over 60, of these, chillers in their region he, said even know offhand how many manufacturers, offered the NBC's but. They've installed. NBC. Chillers from Smart York multi, stack Arctic. Cool and Dyken in region 7, JJ. I don't know if you're aware of any other additional, manufacturers, Oh. Mike. I. Just. Could say just, doing, a first-rate look on online that, there's a lot, of chillers. Out there that offer NBC, I don't know the exact number. Okay. Thanks. And. My. Like, I want I wanted to follow up that, you asked as far as the warranties, on the, compressors. For mag, bearing chillers uh-huh. And, looks like and, it. Looks like to put five-year warranty so, what we what we asked, normally, would, be a one-year, warranty on workmanship in the chairs plus and extended, four. Year warranty on compressor. Parts and labor. Okay. Thanks. And. Then I think if next question might be four years well one you might not know but David, asks regarding, the incentive, do, you know of an expiration date for the incentive, and then you may want to qualify, I think. Utilities, that you were talking about of course are somewhat you need to reason 7 so. There. Is an expiration date, as to, when. When. We complete, product that we have to we, have to submit the paperwork to, the broker and, then. Typically. When. We perform, these projects, after, they accept our applications. They. Have to verify the energy, savings. Basically. There's a pre inspection there's a post inspection and they, usually do provide a deadline, on when. We. Have to complete the project, oftentimes. It's, usually toward, the end of the calendar year unit. Or the end of November, some. There are some brokers, where let's say we aren't able to complete the project they'll. Carry it over to. The. Next year. For. The incentive. Now. There's also that is also deadline, on when we submit applications, we unfortunately. Mean. We, were trying to submit yes we were we, were, trying. To submit an, application for, an exterior light without is different from magyar and chillers but they, had a deadline on. Many. Application, we we. Got into late the money had already been exhausted and so, the. Product that our. Project, was not, considered. And and. We couldn't and we couldn't hold up the project for next year because the product is ongoing and, and so. We had to move forward. Hope that answers your question. Desk. Thanks, and, then I think best questions for you as well one man. Asked for the whole building energy is consumption, I believe this is the to. Your. Presentation, the whole building energy use. With. Those graphs whether, normalized. Mmm. That's a good question I. Don't. Know offhand if they are I can, I can. Look.

Through That and get, back to you on it okay. Thanks. And then both Doug and Gary. Asked, if. At the Thornberry if there was improvement after, training I noticed in the chat that you said but. You don't have post training performance. Data so we don't know yet no. But we can compile the data and provide and get. That out to to. The guys so yes we. Don't have it a we can compile it. And. Then Brian cinclant asks, that the chillers meet the p100, requirements, and they do. Who. When. Scott shines, in on the maintenance of, the. Mbc chillers that they require quarterly, mains to check accelerometers. And capacitors, so thanks Scott. And. Then he also says that the cost overall for that maintenance there's not that much. Difference. Compared. To an annual. On the centrifugal chillers. Let's. See. Can. SRAM just, kind. Of. Think. Of the primary presentation. No. Get the cooling towers in the EH, building of low grade and, that does its impact. Of course the condenser. Water temperatures, which is why they kind of skewed towards the VSS. At that site but of course it's all side dependent. And. Then. We have an attribution, to the quietness, of both, chillers. People. Still eats. Mechanical. Room. A, question, for Dan and. AJ. Is. There, any reliability, data available. On the VSS, and NBC, chillers given that they're both relatively, new, we. Have a reliability, data from the studies over a year what is Ernie can be on that assure. Aware of. This. Is Dan I am not aware of that but I can look and see what's available. And. I, think Juan can speak to at least the dependability. Nbc's, one you've had those. Chillers installed for what the last three, to four years maybe in your region. Yes. Correct yes and operating. Pretty. Trouble-free. To. Our knowledge I. From. Talking with our operations. We we. Haven't we. Haven't encountered, supposedly, the lower, convinced or water. Temperature, issues. Although. Like. I've, been, hearing it here at the regional level. And. Maybe something I need to make. Sure I follow up down the field level with with, the equipment. Specialist, and you know hunters that that, actually operate, the equipment on a day to day basis. To. Verify. That and make sure that, this case but we have, any come across like any major. Magnus. Issues that, I've been brought up on with with, the technology. Eight, one this is Chris fumble doin McAllen, I can verify that we've got those smart, D chillers, in our area and we haven't. Had any problems with, them, and. I think we got them, install in 2016. So, as. Far as those go we've been good the ones that you know about in Brownsville. Super. Thanks. Great thanks. Let's. See, Julian. Asked what is he expected, equipment life for. The VSS and NBC. Dan. Or JJ I don't know if you can share any thoughts on that I would imagine they're similar. Uh. This. Is Dan I have no reason to believe anything other than similar equipment lies. Okay. Thanks, the. Man asked that the prices, quoted where GSA, priceless, quotes. Oblique. So those were market prices right Oh. At. The ates building, the. NBC. Chiller was, purchased, through normal channels and. The VSS, seller because. Of the nature of the green crude around we. Were working with budget prices but they were shop third party as. If it was being sold on a government contract in, the price and. It was listed in the report was confirmed. And. Then Joshua. The issue resolved, to run multiple childers a partial, load rather than loading up a single Schiller and the, case of the MBC that's right you staged your chillers so that the chillers, operate. Kind of in their sweet spot. Julian. Asks. Do. You have sound data comparison, to compare sound in the octave, bands and I will say that um we. Don't have that as a part of our study then, there might be someone out there in the marketplace but not that I'm aware of. Does. Anyone know, that cost associated the service in the NBC verse was the conventional, chillers. I'm. Going to take that as NBC, versus conventional, centrifugal. Chillers, does anyone. JJ. Any thoughts on that. Yeah. That we in. The report we as I, noted earlier we. Didn't have any data. On that the. Only only. Only. Something. That it would be lower because of the lack of oil. Requirements. For that particular chiller.

Right. Let's. See. God's. Got a question, JJ. And Dan I'll ask if you know what, is the max cottage manufactured. For. The VSS, and NBC and, how easier, they to get into the mechanical, room are. They modular. Jerry, or Dan any thoughts on that I. Looked. Up I was. Looking up the. Compressor. Manufacturer. And they're making, up. Into the several hundred ton. Compressor. Compressors. Now that. You want to on those chillers, so, assuming. They can operate them you, know install two two, compressors, and it's it's approaching, a thousand tons now. But. I know Juan do you have any one, line, can you off the top of your head state with the largest NBC, is in their region. The. Large the. Largest in our region for manga and chillers at 750. I know, that, when. I went to an OG conference, in Atlanta. Smart. Was care, was gonna carry, my. Great rose I think up to 1,200, tons. What's. In them as far as if they're the larger ones and market I'm not sure offhand but that's. The largest one I'm aware of. Okay. Thanks Dan, any thoughts on the VSS you know, yeah. The variable speed screw unit when I saw this question I just looked, at their website real, quick their largest unit is it five hundred and fifty tons and. As far as much clarity goes but. To, get the units into the, AC chemical, room was, a pretty, era pretty, impressive job with you. They worship modular, they. Were able to get them in place and. As. Far as I know reassembly, with well perhaps acquainted Randy could address that in more detail since they were there every day. Great. Thanks. Chad, ask was a plate exchanger, considered, as a means to utilize low condense for water temperatures, I think. That might be more of a lawn or a Kenny your team question. So. The. Question was did we did we consider, looking, at like, flat plate heat exchangers, it. Doesn't specify that I would think. If. You don't know that's fine but I actually. We'd, come across some, some. Cases. Where we had. Where. We had some I. Think. I think here in this building here in the land and building we have a flat plate heat exchanger, but we, hadn't been using and in, the unit because of the because. Of the magma and chillers. They've. Been talking, with Dana I. Don't. In many cases, things like when we when. We've installed, these night there and chillers we've, in. Places, where we where we have flat. Plate knee exchangers, we basically. Deactivated, and because. Apparently the night manager is a more energy efficient although I know, the flat plate exchanger, is beneficial, in that it, does provide free, cooling. And. But, apparently. From, from, talking internally, with robbers group they're more, comfortable going with the magnet chillers. In. Places where we have slightly, heat exchangers. Okay. Thanks, mmm, let's, see. Okay. Ask is there any independent, oil and refrigerant analysis, analyst. Analysis. Done. After the same time any frames or at the end of test period. And. I'm going to prefer the our study and maybe if you can just again talk about how we you. Know does our best to operate side by side stay, on and day off I. Yeah. The answer the questions. No we did not. Do. Any oil or refriger analysis. At. The end of the test period. Okay. Thanks I misread that um. He. Um. Craig, Campbell, states, that some NBC chillers can accept condenser, water temps down to 36, degrees so. Again I think that's a design issue. That. The, Danfoss. Titan rats told us you know if you specify, convinced. For water chimps don't design to it. That's. Who money. Ask if you can get copy the slides, Andreea I assume that's the case. I'm. Just going down the questions. Dan. Asks, this, is kind of out of a little. Bit let's give it a shot now Dan asked a new address free cooling selection, there. Seems to be some interest in that um I don't know if JJ. Had any other thoughts on pre-cooling, when having. These two chillers. Installed. Any. Thoughts on that given that they operate well, with a low low level. Yeah. This is band, free. Cooling is very, much a site-by-site. Item. That has to be decided, utility. Rate structures. Dew. Points. In. The climate zones there. Are myriad variables, that go into that and the discussion, would be too complex, for this case for this discussion. Here. Let's. Thanks. And. Then someone asked about the lower tonnage, range for the VF s do you recall what, you found was. A lower limit I don't. Recall off the top of my head okay, thanks. Jose. Alvarez. Mentions. That NBC chillers can unload to less than 5% based, on the manufacturer design. Let's. See. Then. Gary states you believes the train offers NBC as well. Zack. Asks. JJ. This question, for you the. Table of comparison, between the, or.

Know Maybe this is sorry, dan for you the. Table of comparison, between DSS, and NBC, the. Coefficient. Of performance shows. That, an official. Benefits. Of NBC. At 1% 25%. Loads is that for cooler weather states how, does that factor in for southern states. This. Is dan when. When. You're looking at that load, profile 100%, down to 25% that, is. Based. On a percentage of peak, load. And peak. Load is not so much a trait of the climate, zone that it's located in, peak. Load in the amount of time that it spends in a part load is more of a factor of what. Is your building how, is it operating. Is it a conventional, office building. That. Goes, from empty on weekends, to full in the summertime so. It's, really it. Certainly. Climate, is a, part, of what. Drives a decision, we are looking at a low profile, but, also how the building, operates. Very. Great thank you. Joe. Says the comparisons, with between VSS and NBC's chillers so are there chillers that are both the SS and NBC, and the answer is no we. Had a VSS. Chiller and a. Separate NBC. Chiller tunafish loose in the Yates building. Let's. See. Chief. Sim, makes. The statement oh he's what we'll give him the presentation, data was table, ISM decibels, not an octave and we. Use decibel, range we didn't use octave band so. So. We didn't test frequency, levels I believe that's the case right then. That. Is correct I said okay. Let's. Say someone. Asked. The question what happens if at NBC, if the power to the bearing failed either. By a power outage or electronic, failure and Jose answers if there's a power failure the NBC, will close down to a safe stop. Let's. See. And. Greg. From region 4 says, that they've been installing NBC's for 8 years. So. That's you, know long time duration for dependability they. Seem to be happy with him. See. Bob Braun asks, are these chillers consequentially. Zorkin they adjust a variable flow, chilled. Water and. Convinced. For water temperature flows, i. Don't. Recall off the top of my head okay thanks. Josh. I asked a variable speeds and triples been considered, for comparison, and the answer is no not for these specific studies. Let's. J. Dimension somatically chillers can be bought with knock-down kits so they can be shipped from similar smaller, components, so, that confirms what Dan was saying I. Think. Andre. Oh that's it for all the questions. Feel. Free to, reach. Out to us and we'll see if we can get those answered, and. Mike. Said this attending. Is. Available, for continuing, education credit. After. The completion. Shortly. You'll be receiving a very short five question survey and by. Completing that survey you'll. Receive. Continuing, education, credit if you don't receive the survey for, any, reason. Please reach, out to Michael Hopson, his. Email. Is. Michael. Hopson. At gsa.gov, and. He. Can get, you set up with those continuing, education, credits I'm good that should have been on the screen here I'm going to show. It here from, a previous webinar. So you have that information, of how. To get to continuing, education credits. And. Thanks, very much for all of you for participating and, for all, the speakers and, again. We. Hope to see you at next, thank. You. Thank. You.

2018-01-26 02:32